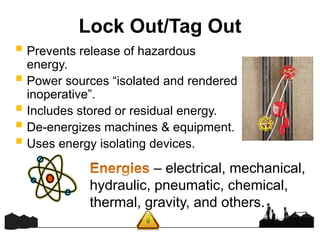

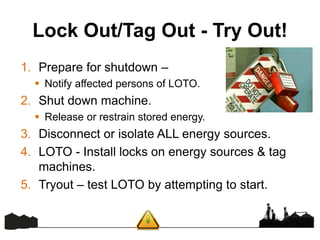

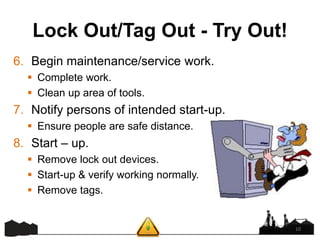

This document discusses lock out/tag out (LOTO) procedures, which are intended to prevent injuries from unexpected startup of machines or equipment during service or maintenance. It notes that LOTO is required by OSHA, protects employees, and involves written procedures to isolate energy sources to machines to render them inoperative before any work is done. The document provides details on LOTO requirements, including that only authorized employees can perform LOTO, all employees must be trained, proper locks and tags must be used, and procedures must be reviewed annually. It emphasizes that LOTO should be followed each time work is done to ensure safety.