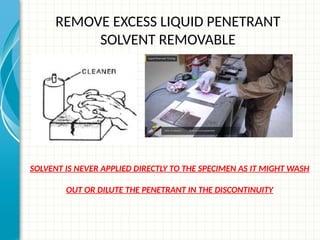

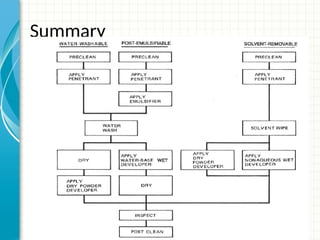

This document provides a comprehensive overview of liquid penetrant testing, including its principles, necessary surface preparation, and various methods of application. It highlights factors affecting penetrant capability, discusses types of penetrants, and outlines essential testing procedures and post-cleaning processes. The conclusion emphasizes the effectiveness of penetrant testing on a range of materials, as well as its limitations in detecting certain types of discontinuities.