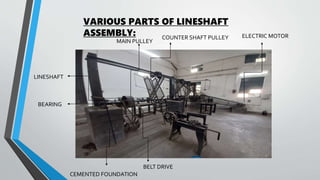

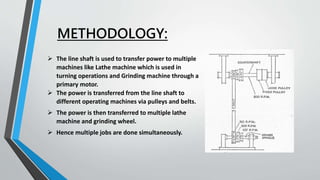

This document discusses the maintenance of a line shaft and its applications. It provides background on line shafts and how they were historically used to transmit power from central sources to machinery throughout workshops. It then details the specific maintenance performed on an installed line shaft, including lubricating jammed bearings and pulleys, replacing worn belts, and realigning misaligned pulleys. The objective of maintaining this line shaft was to make it functional again for demonstrating its use in industrial applications like farming and grinding operations.