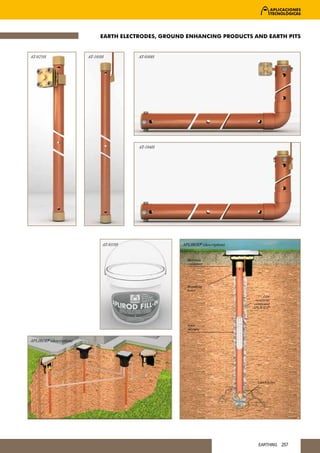

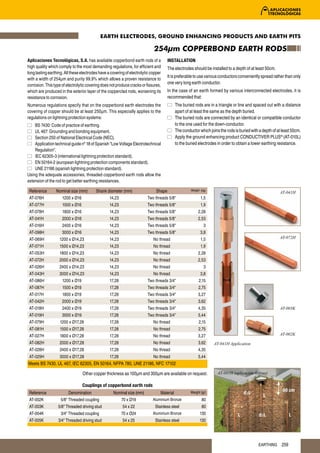

This document provides information on earthing electrodes, ground enhancing products, and earth pits used for lightning protection and electrical installations. It discusses the importance of a suitable earthing system and describes regulations and minimum requirements for different types of electrodes according to various international standards. Enhanced electrodes called APLIRODs are described, which use ionic compounds to lower the resistivity of surrounding soil in low-conductivity areas. Instructions are provided for installing and connecting these electrodes.