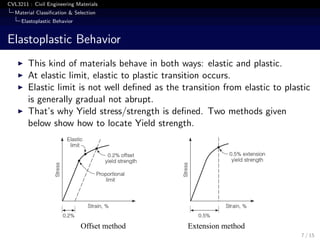

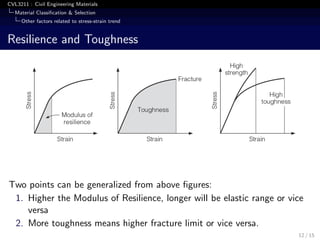

The document discusses the classification and selection of civil engineering materials, highlighting key factors such as mechanical and non-mechanical properties. It elaborates on the stress-strain relations, including elastic, elastoplastic, and viscoelastic behaviors of materials, as well as modes of failure and safety considerations. Additionally, it covers economic factors and material characteristics, like density and thermal expansion.