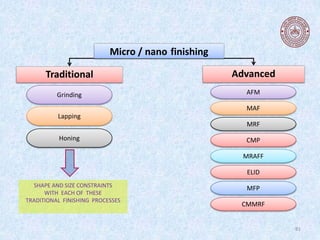

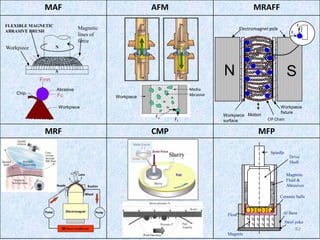

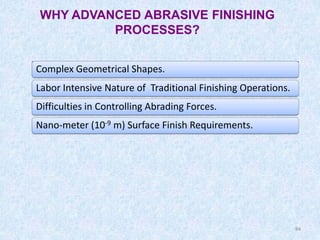

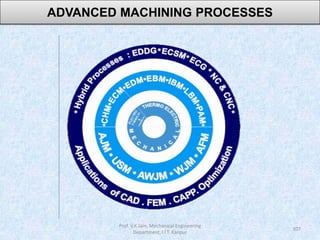

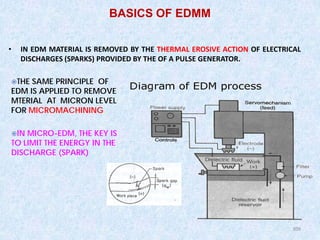

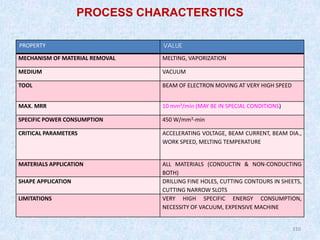

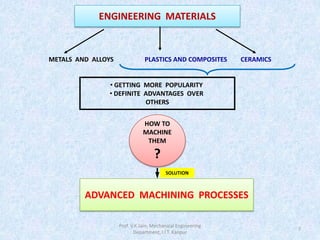

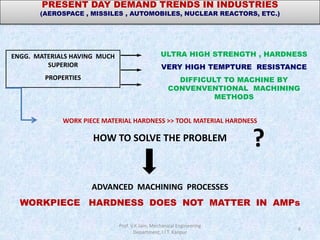

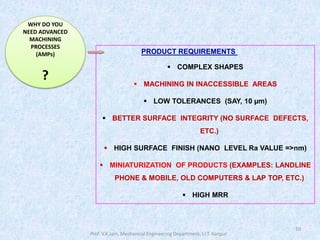

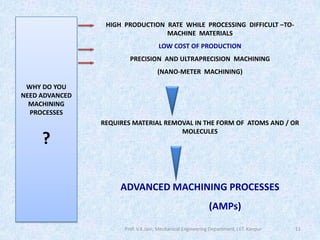

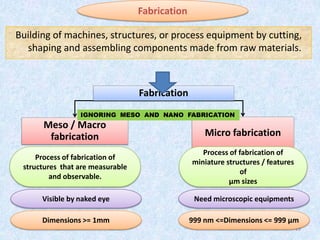

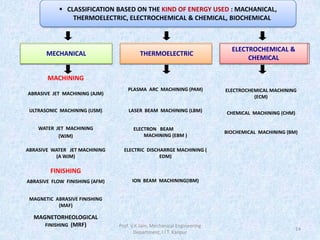

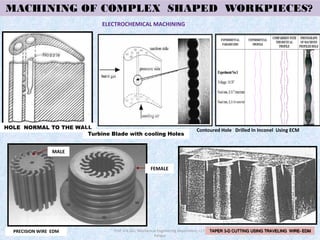

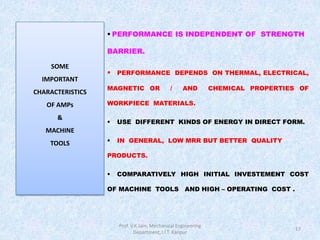

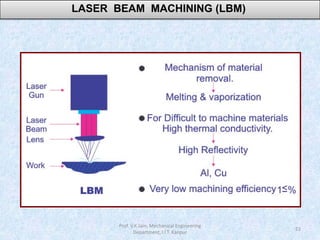

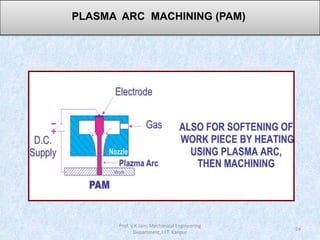

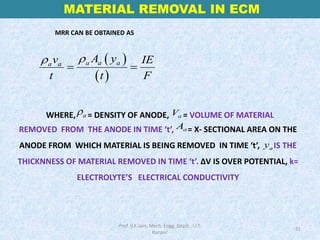

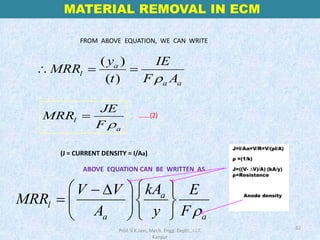

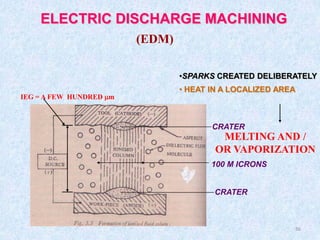

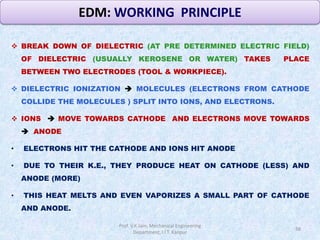

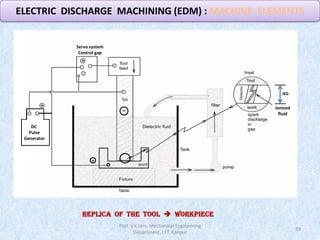

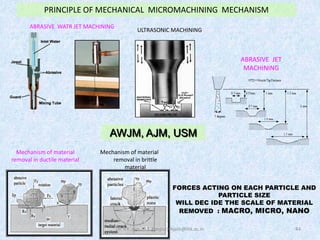

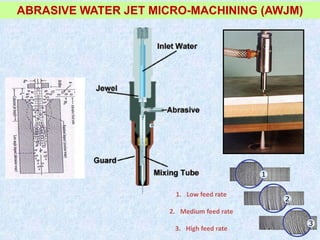

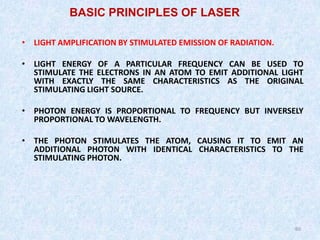

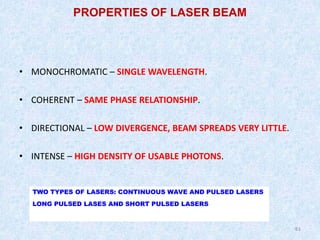

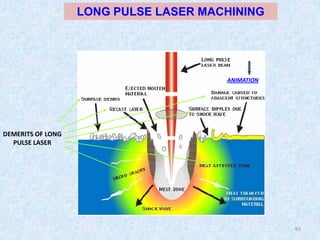

The document provides an overview of advanced machining processes (AMPs) and their importance in modern manufacturing, specifically addressing the challenges posed by high workpiece hardness and complex geometries that conventional machining methods struggle to handle. It discusses various techniques such as electrical discharge machining, laser beam machining, and electrochemical machining, highlighting their applications in producing high precision components and miniaturized products across industries like aerospace and electronics. The document emphasizes the need for AMPs to meet evolving product requirements, ensuring better surface integrity, low tolerances, and high production rates.

![79

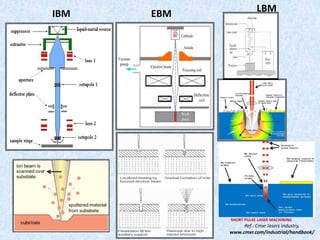

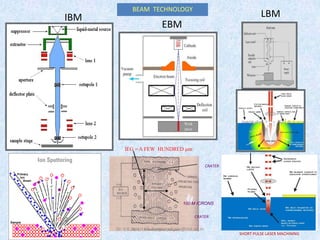

TYPICAL MATERIAL REMOVAL RATE IN ION

BEAM MACHINING

TABLE1: REMOVAL RATES BY IBM (SPENCER AND SCHMIDIT,1972 [1])

DATA : ARGON ION BEAM 60 TO 700 FROM NORMAL

PRESSURE = 3X10-4 TORR

VOLTAGE = 6 KV

CURRENT = 100 µA

CURRENT DENSITY = 1 MACM-2 OVER 1 CM DIAMETER AREA

MATERIAL REMOVAL (MILLING) RATE, (µM HR-1)

QUARTZ 2

GARNET 1

CERAMIC 1

GLASS 1

GOLD 2

SILVER 3

PHOTO RESIST MATERIAL (KTFR) 1

PERMALLOY 1

DIAMOND 1](https://image.slidesharecdn.com/lecture5ampmmnf-200914-240403183426-910c3258/85/Lecture-notes-for-engineering-students-for-all-colleges-79-320.jpg)