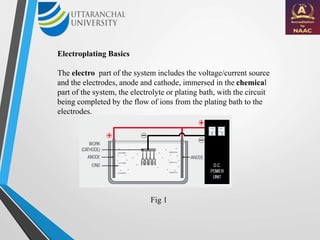

This document provides information about electrolysis and Faraday's laws of electrolysis. It defines electrolysis as a process of coating one metal onto another through electro deposition to modify surface properties. It explains the basic components and process of electroplating, including the power supply, electrodes, electrolyte, and ions transferring between the anode and cathode. It then describes Faraday's two laws of electrolysis, which state that the mass of ions liberated at an electrode is directly proportional to the quantity of electricity passing through, and that the masses of different substances liberated are proportional to their chemical equivalent weights. It also defines related terms like current efficiency and energy efficiency.