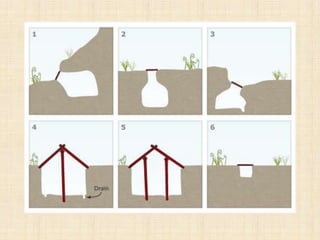

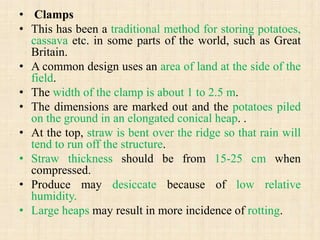

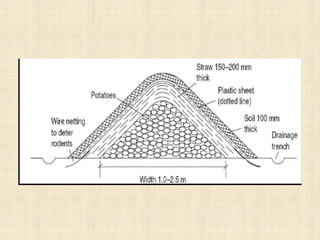

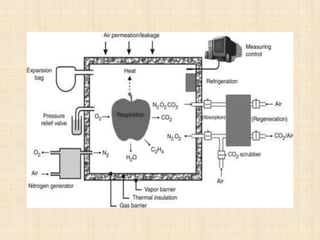

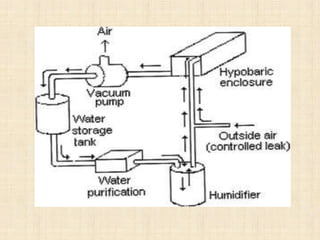

The document discusses two main methods of storage for fruits and vegetables: traditional and advanced methods. Traditional methods include techniques like in situ storage, pits, clamps, cellars, and barns, while advanced methods comprise low temperature storage, controlled atmosphere storage, and irradiation. It highlights the advantages and limitations of each method concerning preservation and quality maintenance.