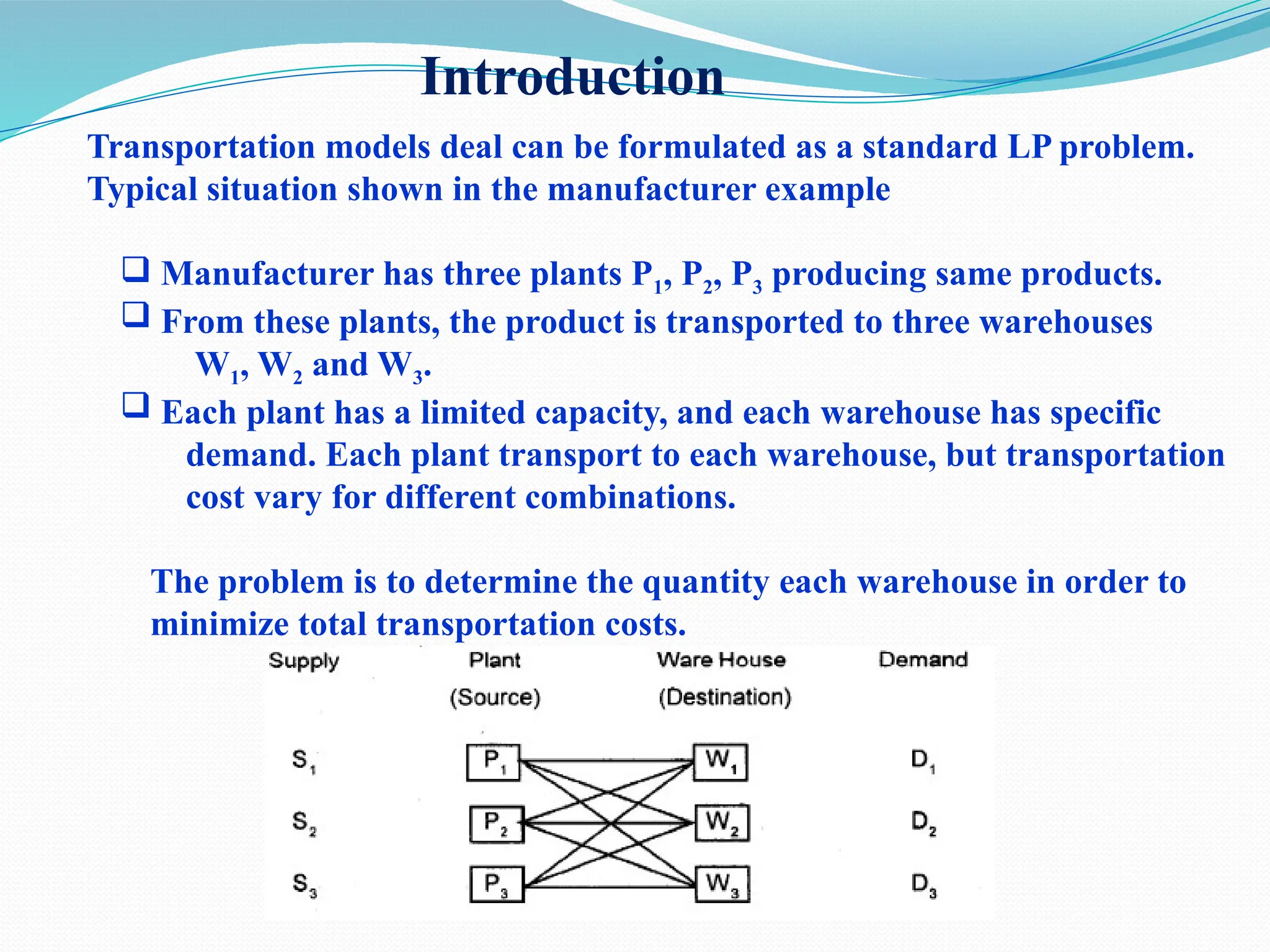

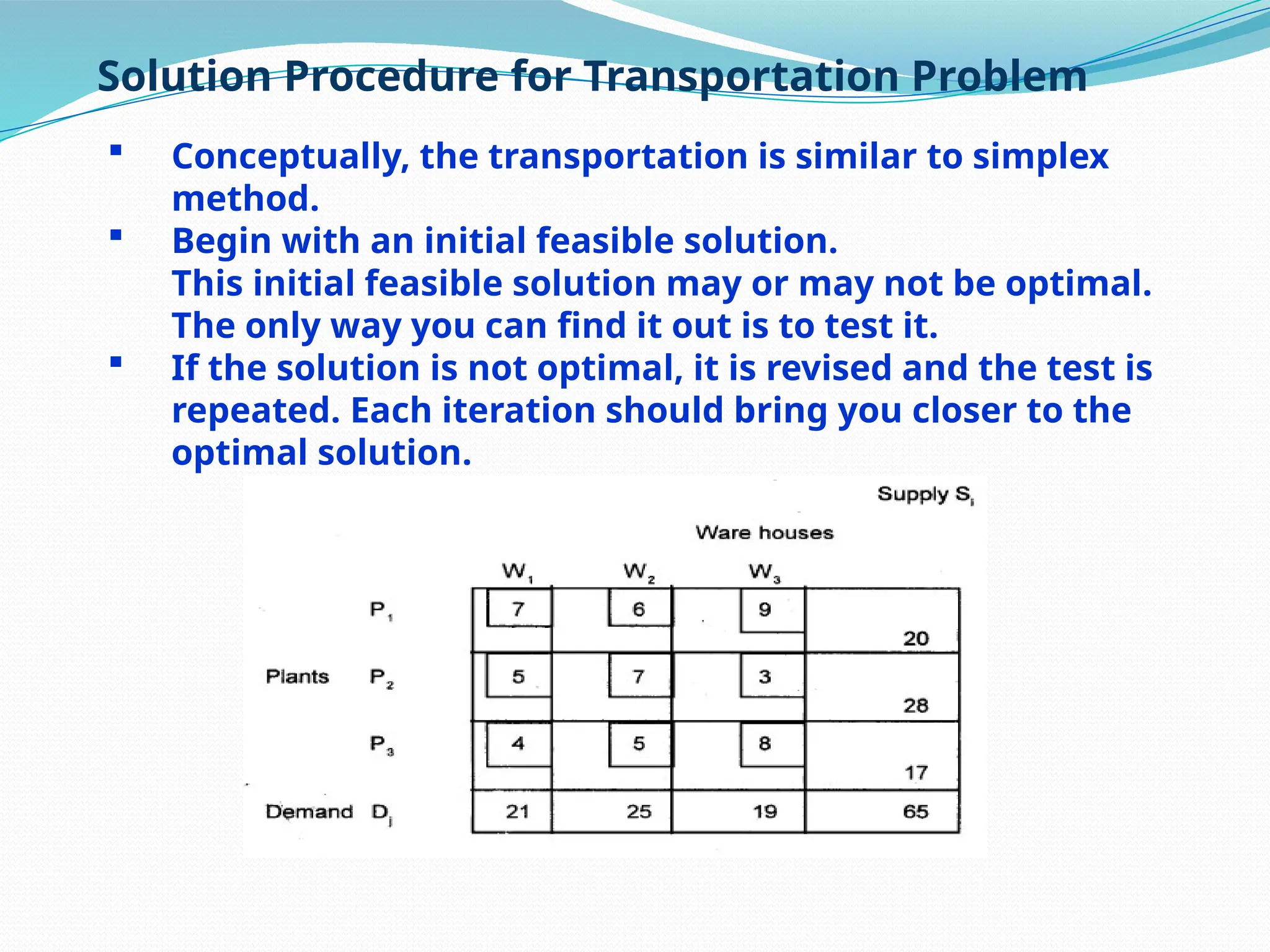

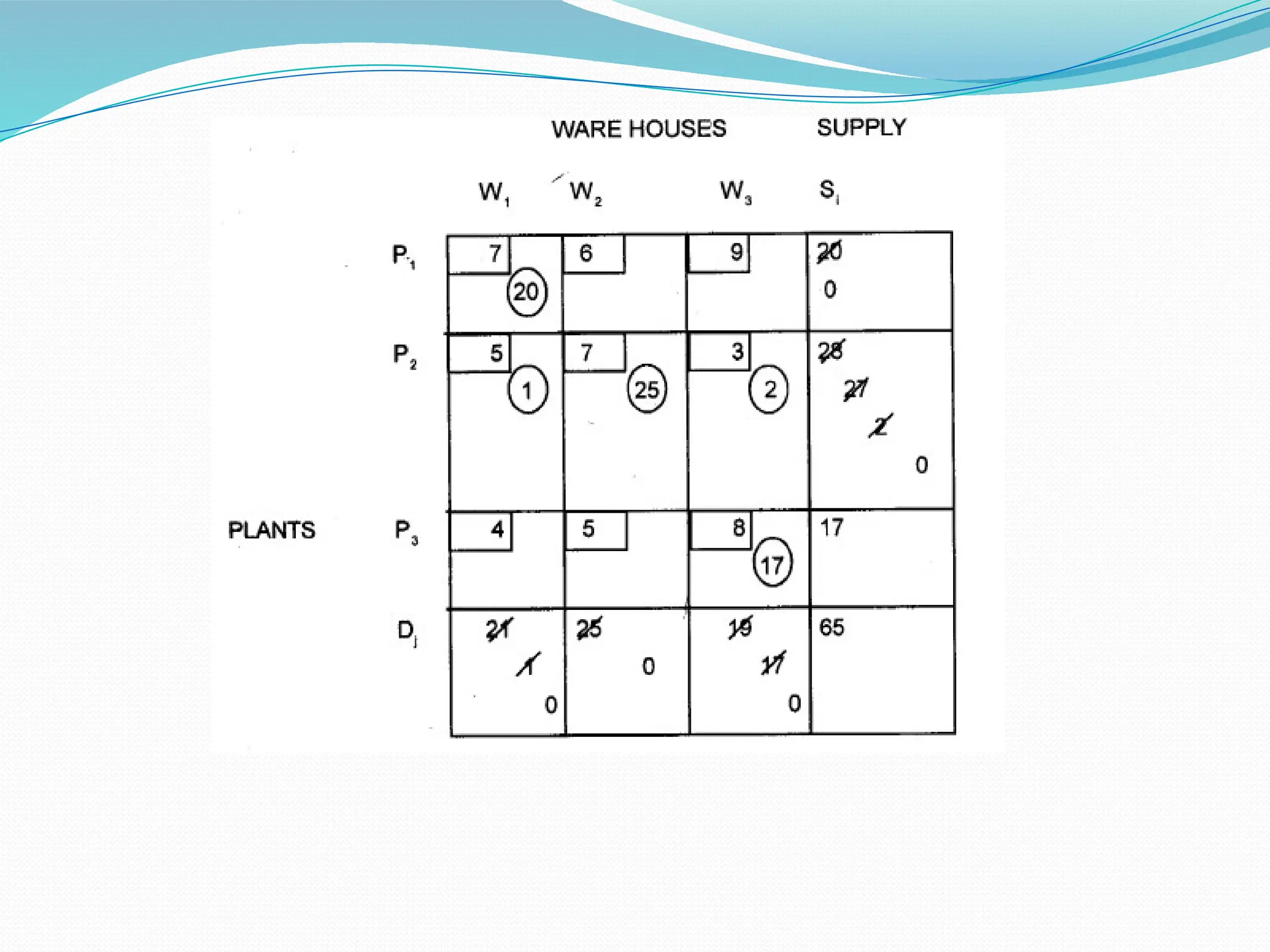

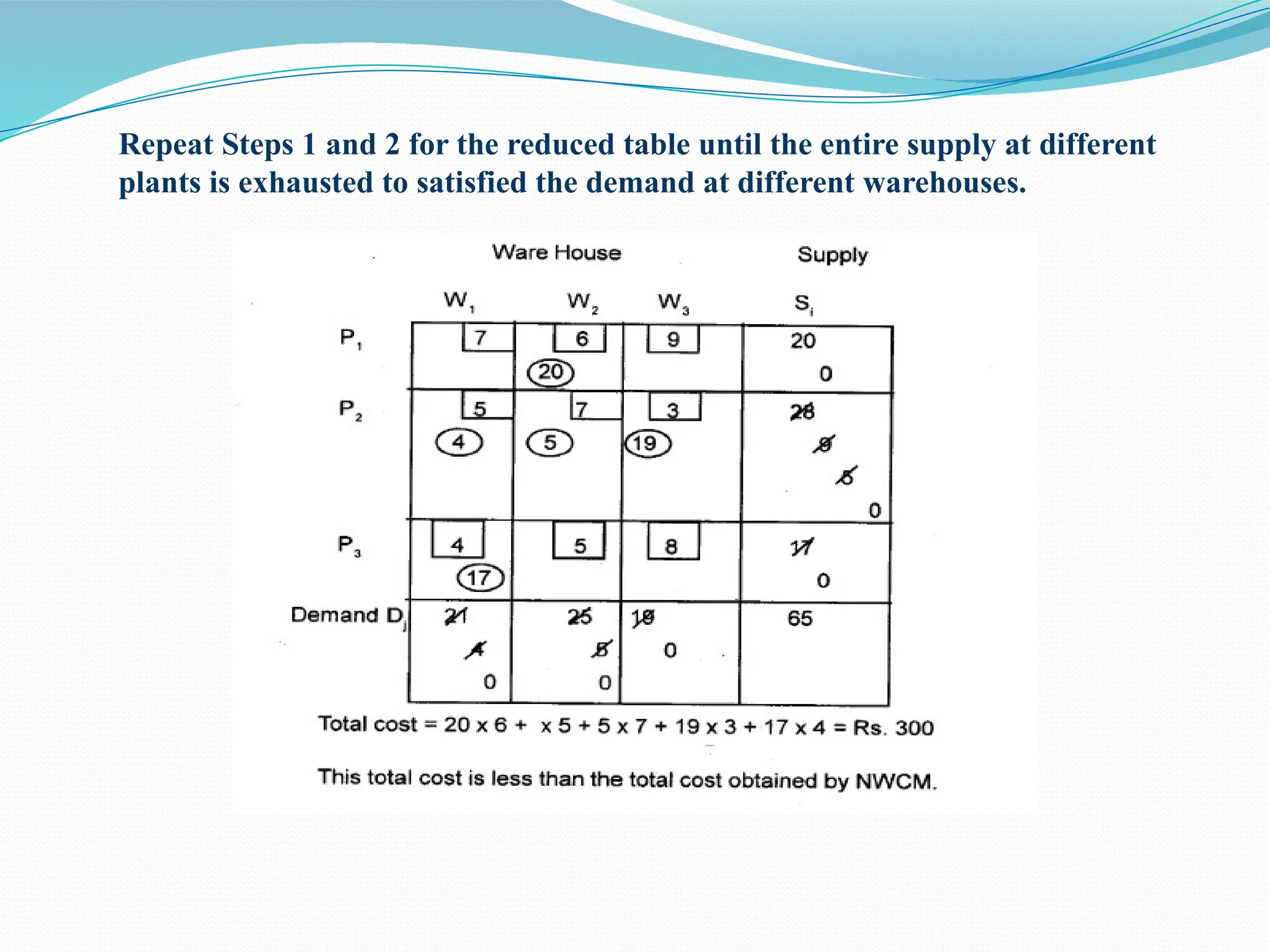

The document discusses the transportation problem in operations research, focusing on finding initial feasible and optimal solutions for transporting goods from manufacturers to warehouses while minimizing costs. It outlines solution procedures including the North West Corner Method, Least Cost Method, and Vogel's Approximation Method for generating these solutions. The document also covers how to formulate the problem involving decision variables, objective functions, and constraints.