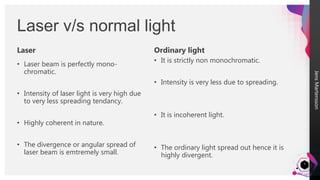

A laser is a device that emits light through optical amplification via stimulated emission, producing a narrow beam of light that is highly monochromatic and coherent. Lasers are classified into types based on their gain medium, including gas, solid-state, fiber, liquid, and semiconductor lasers, and they have a wide range of applications from communication to medical treatment. Despite their advantages like high efficiency and precision, lasers can be expensive, delicate, and potentially harmful if not handled properly.