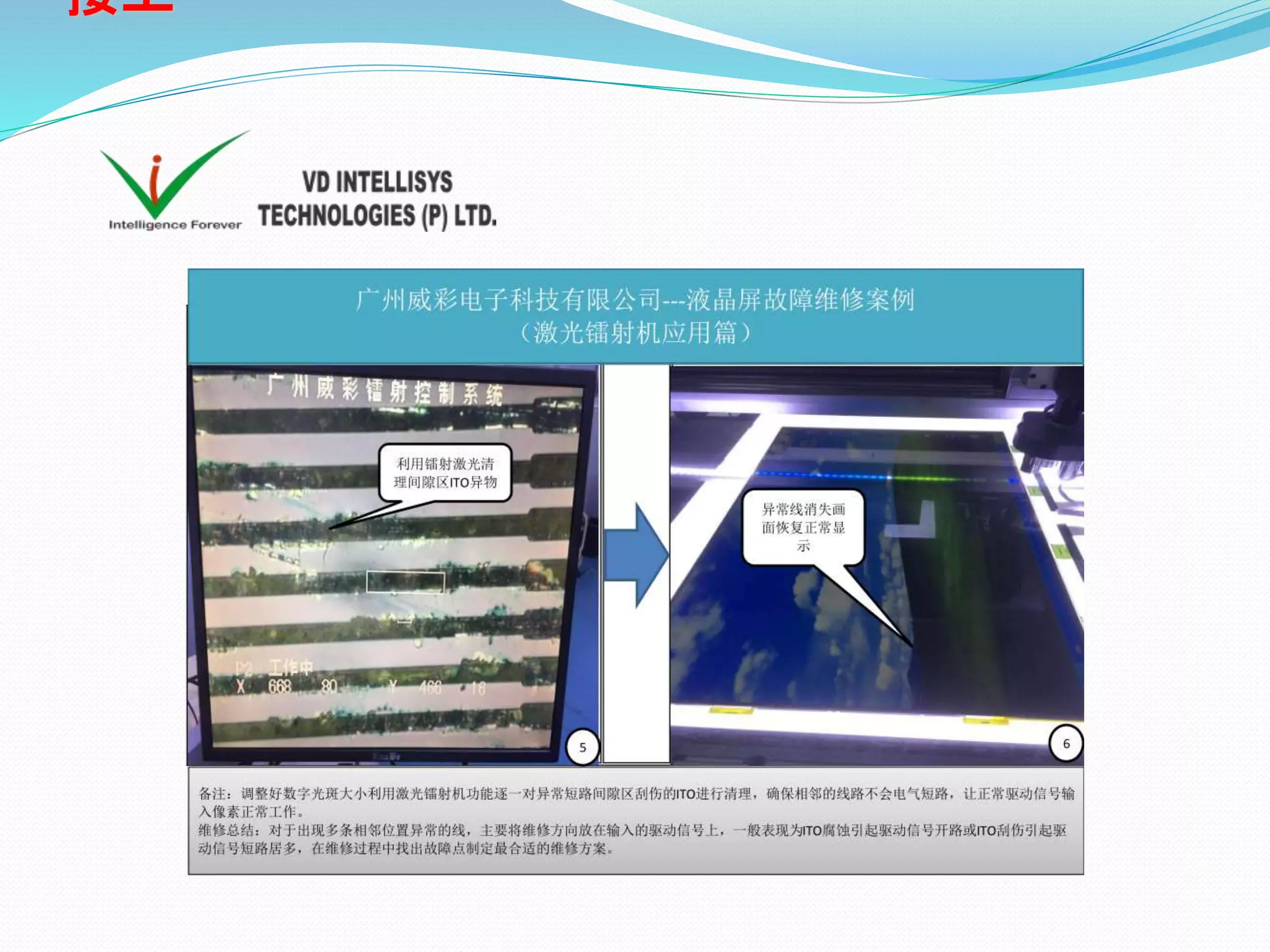

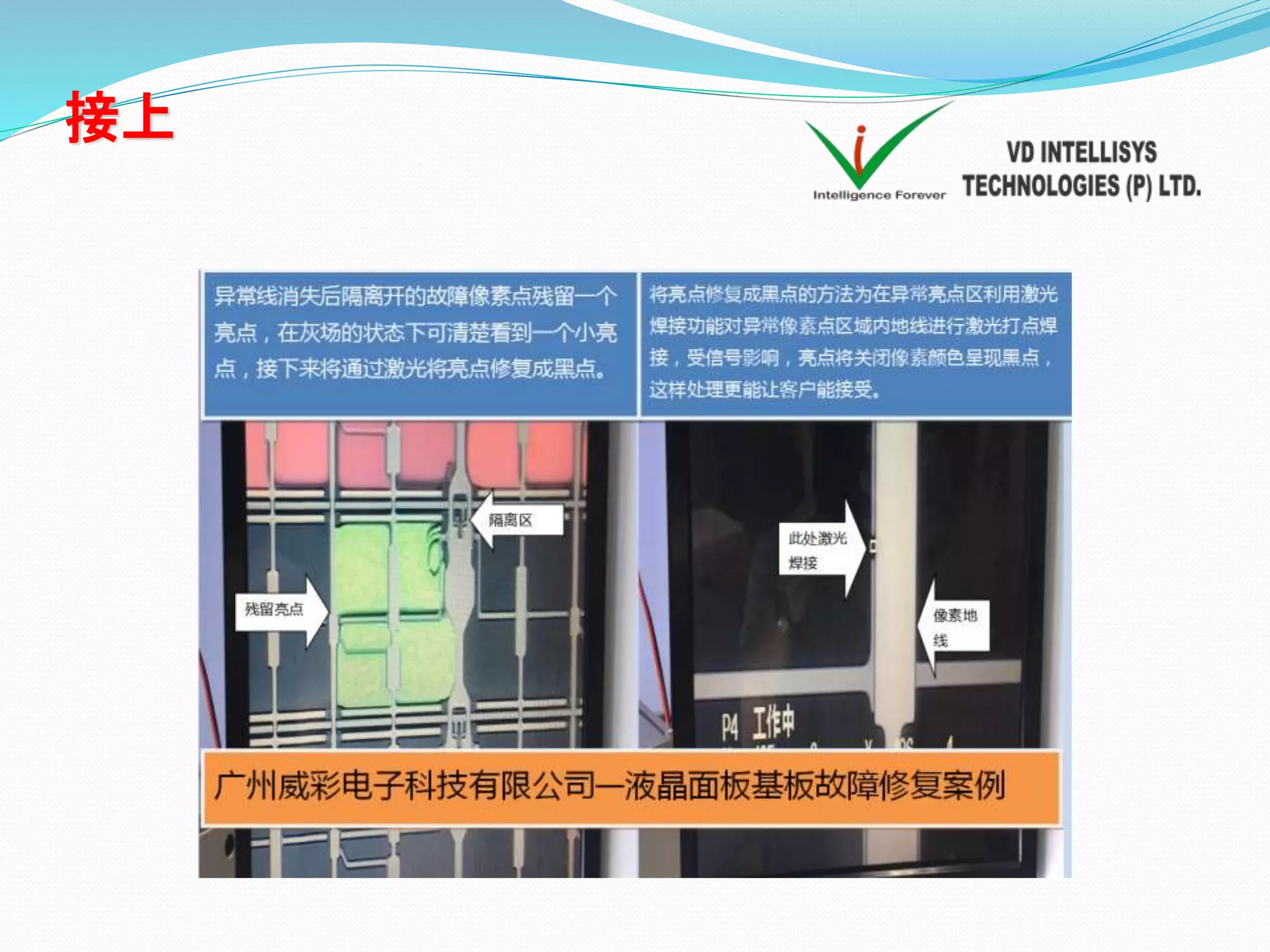

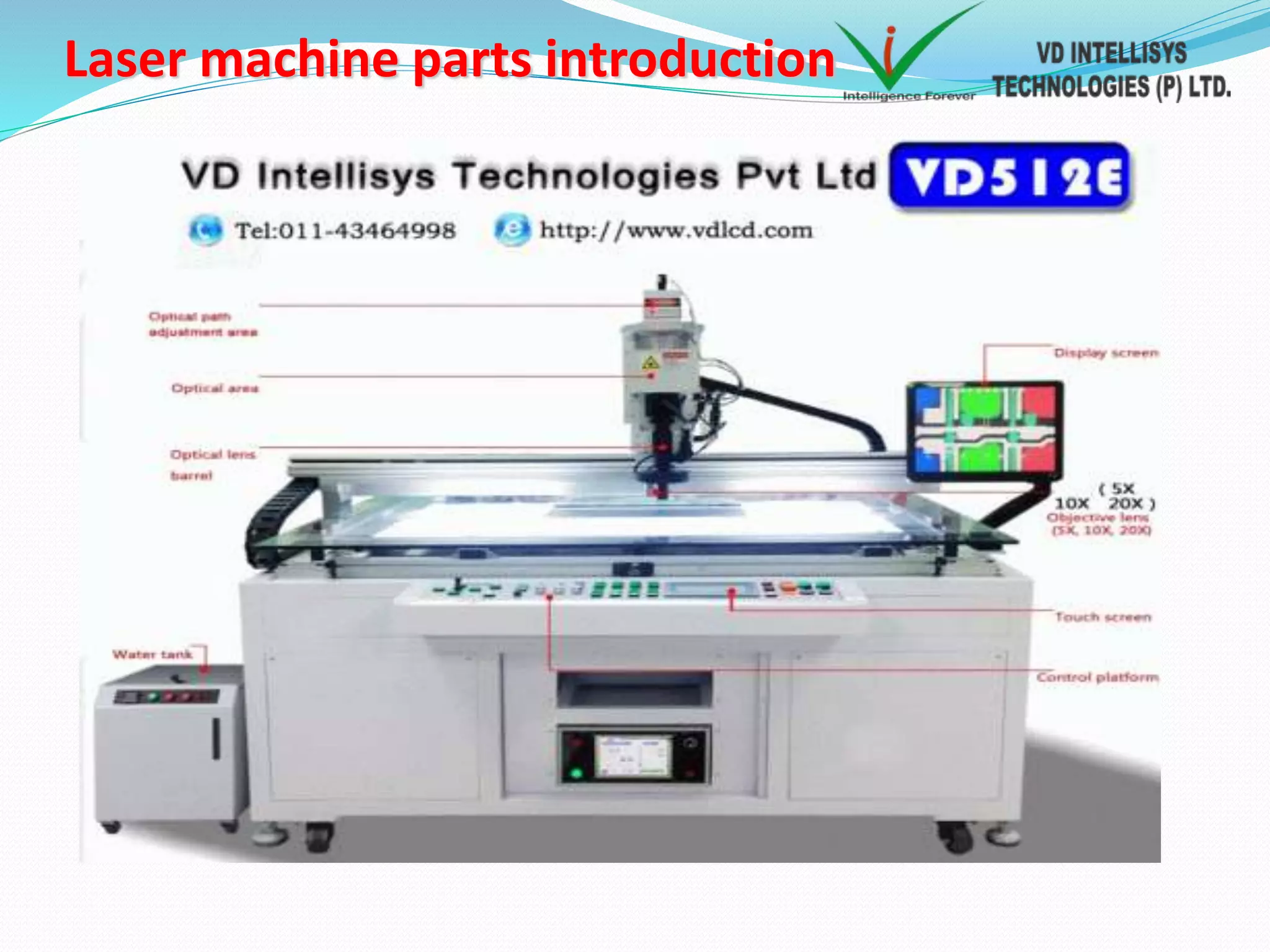

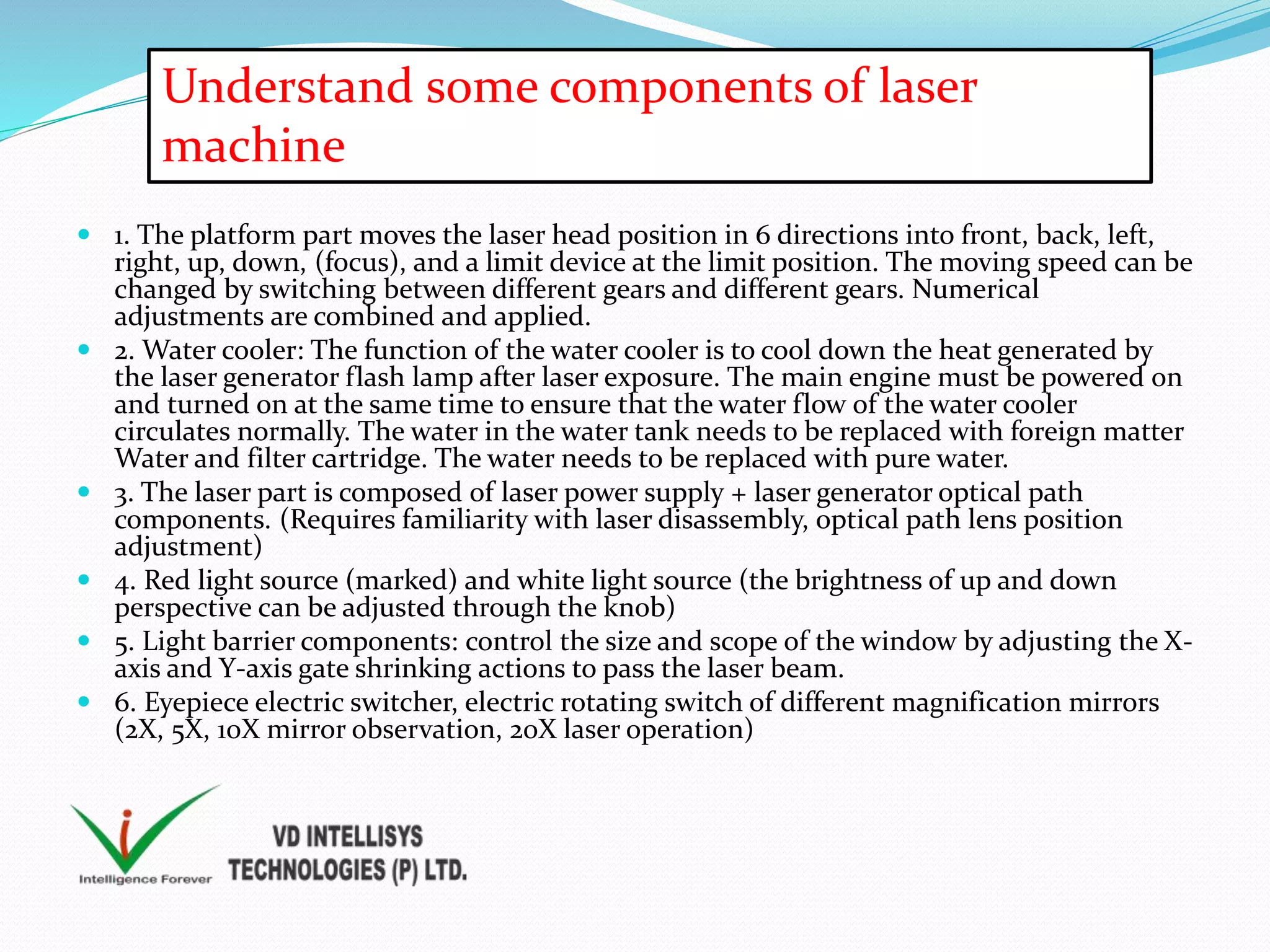

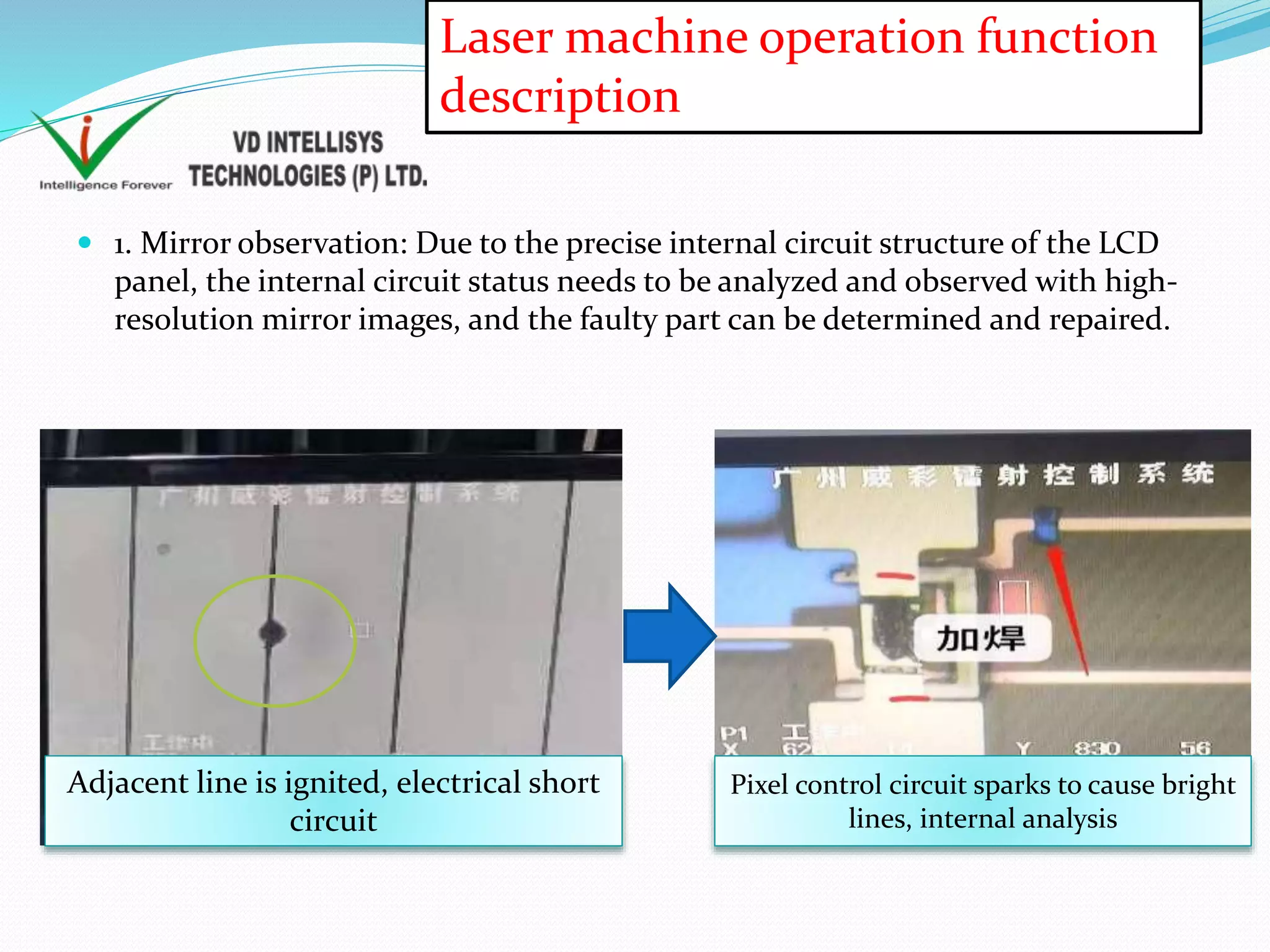

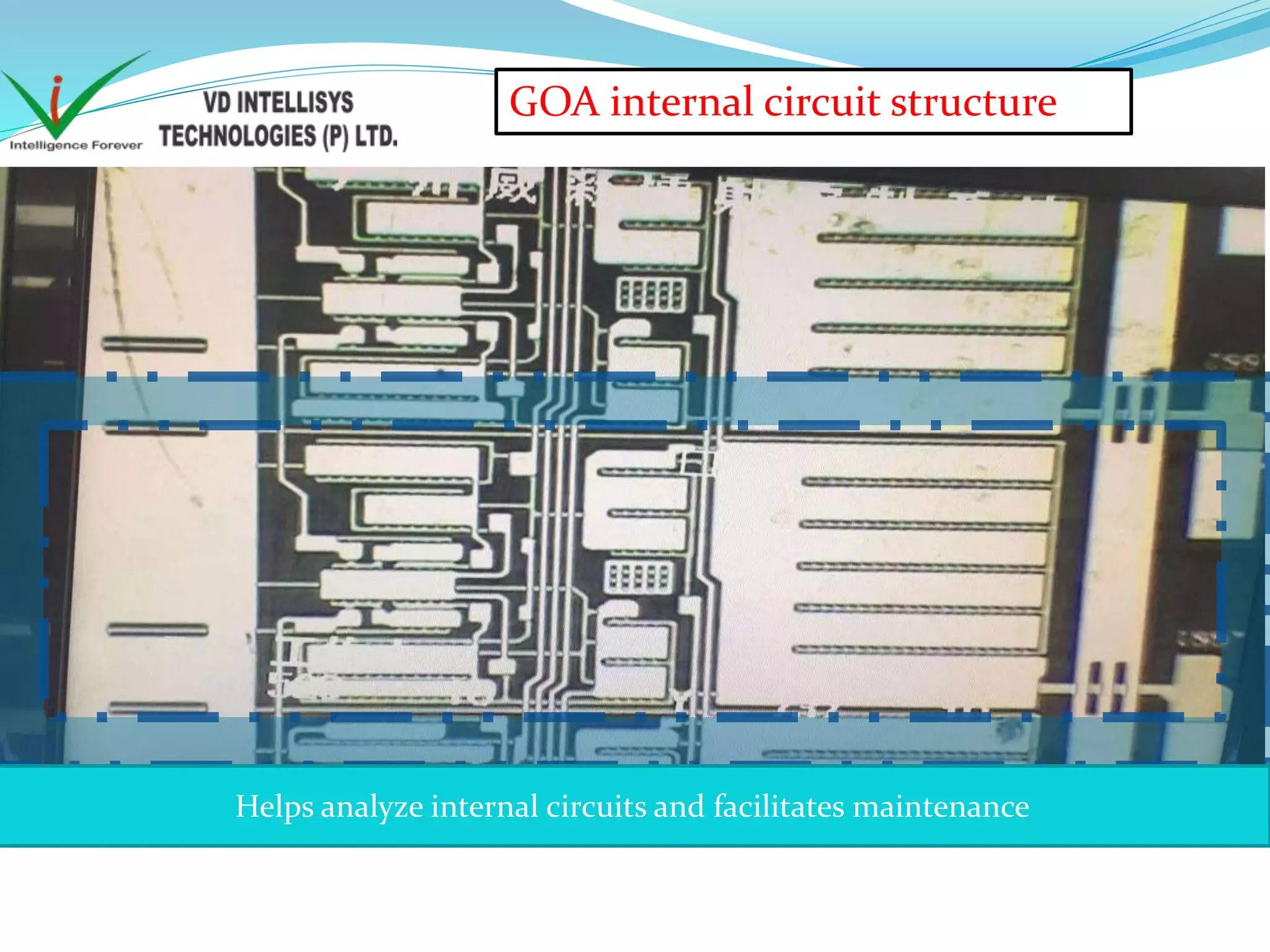

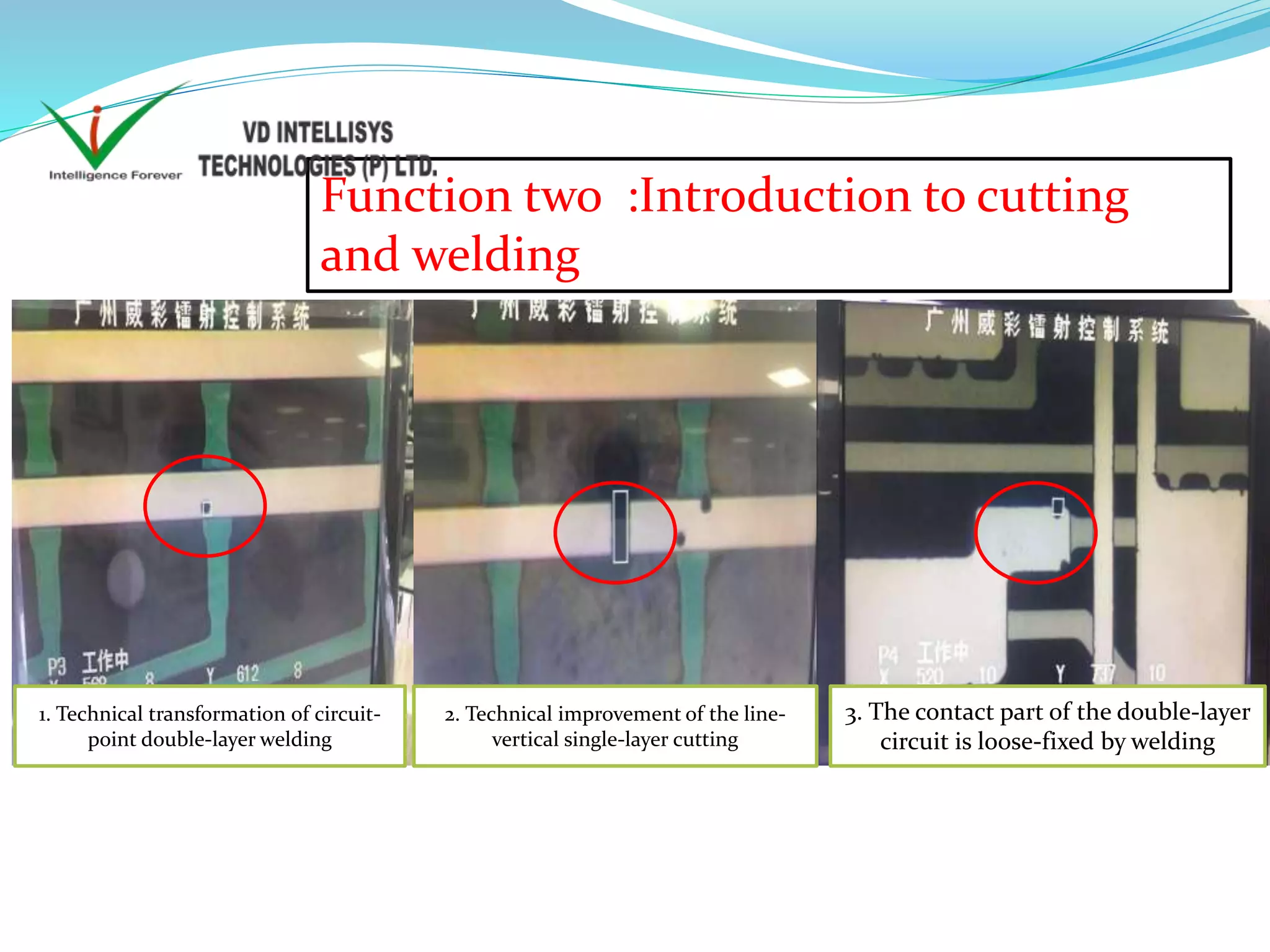

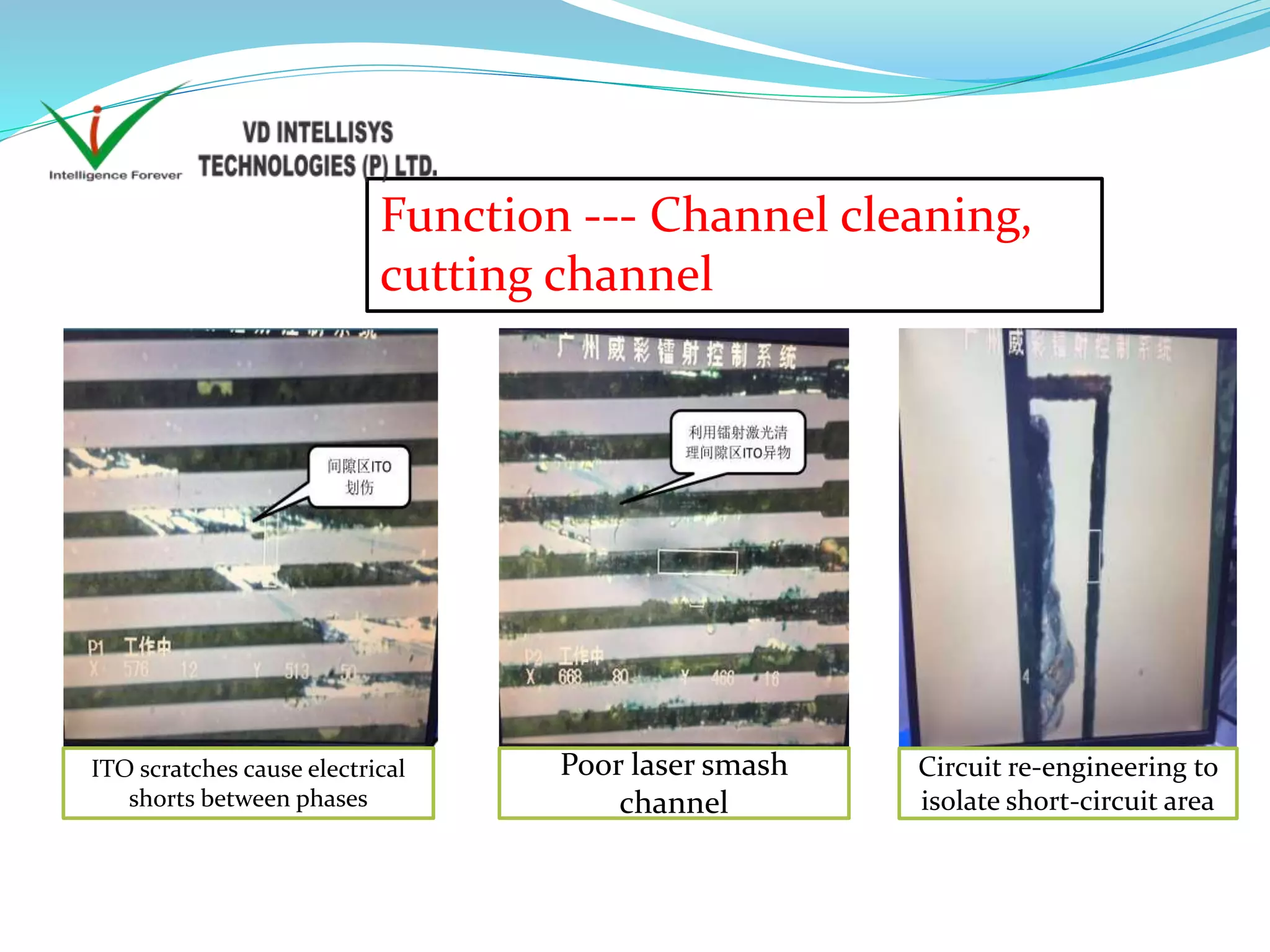

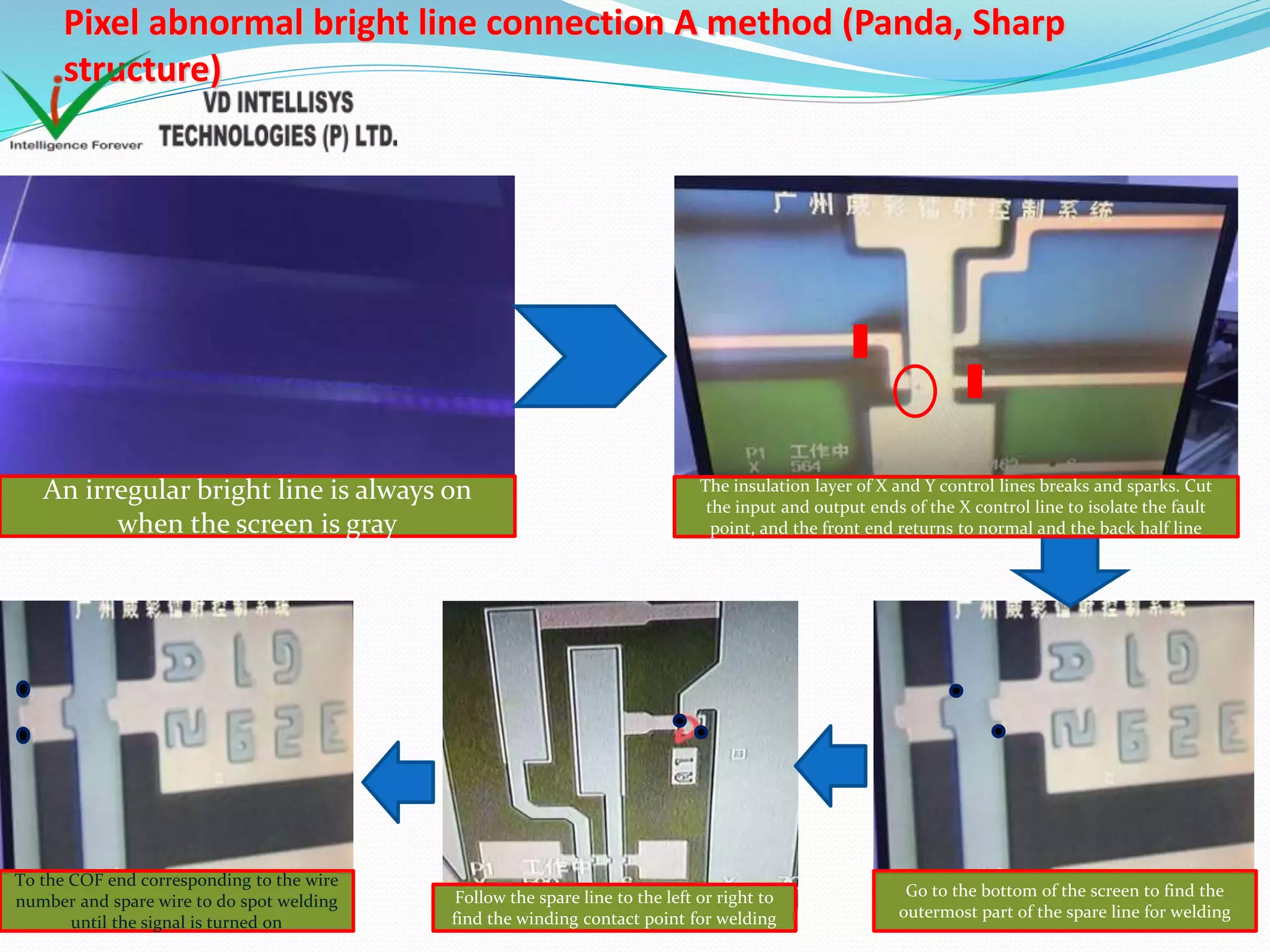

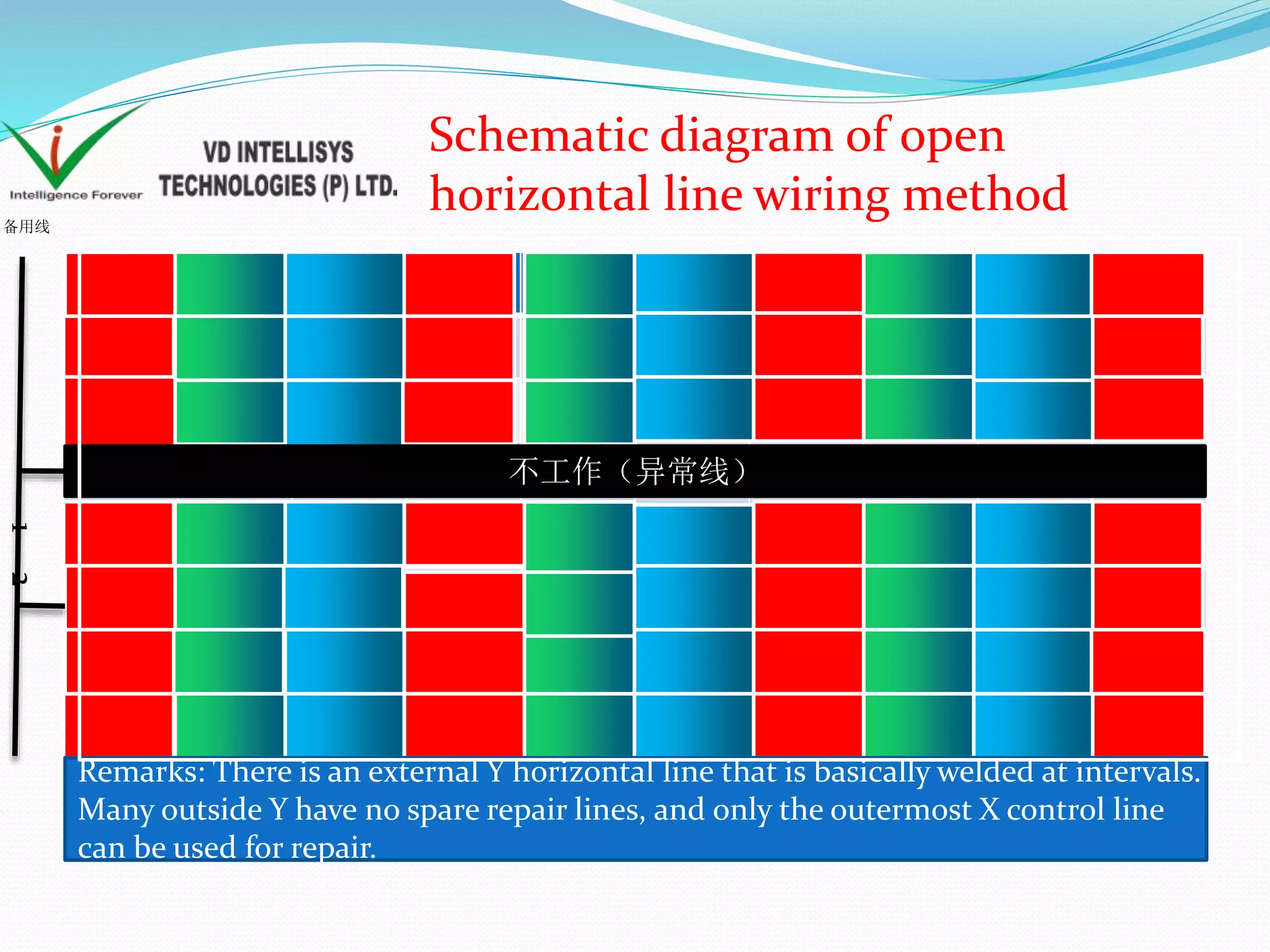

The document outlines a training program for laser LCD repair technology by Chiptroniks, detailing the operation and maintenance of laser repair machines used in the LCD screen repair industry. It covers various faulty conditions, troubleshooting methods, and repair techniques for common LCD panel issues, emphasizing the efficiency and cost-effectiveness of using laser technology. The program includes practical training components on equipment handling, internal circuit analysis, and advanced repair methods for addressing specific faults in LCD panels.

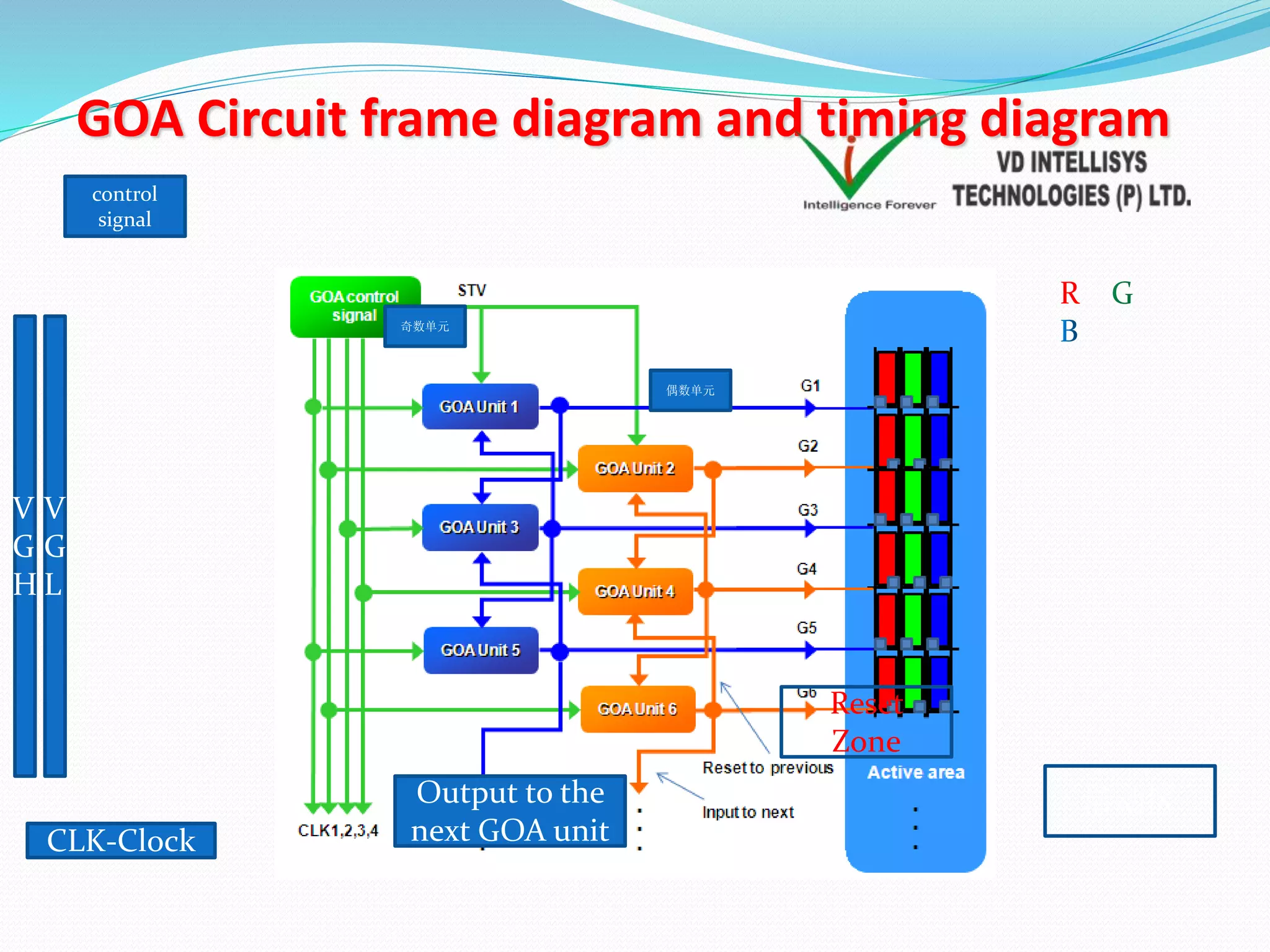

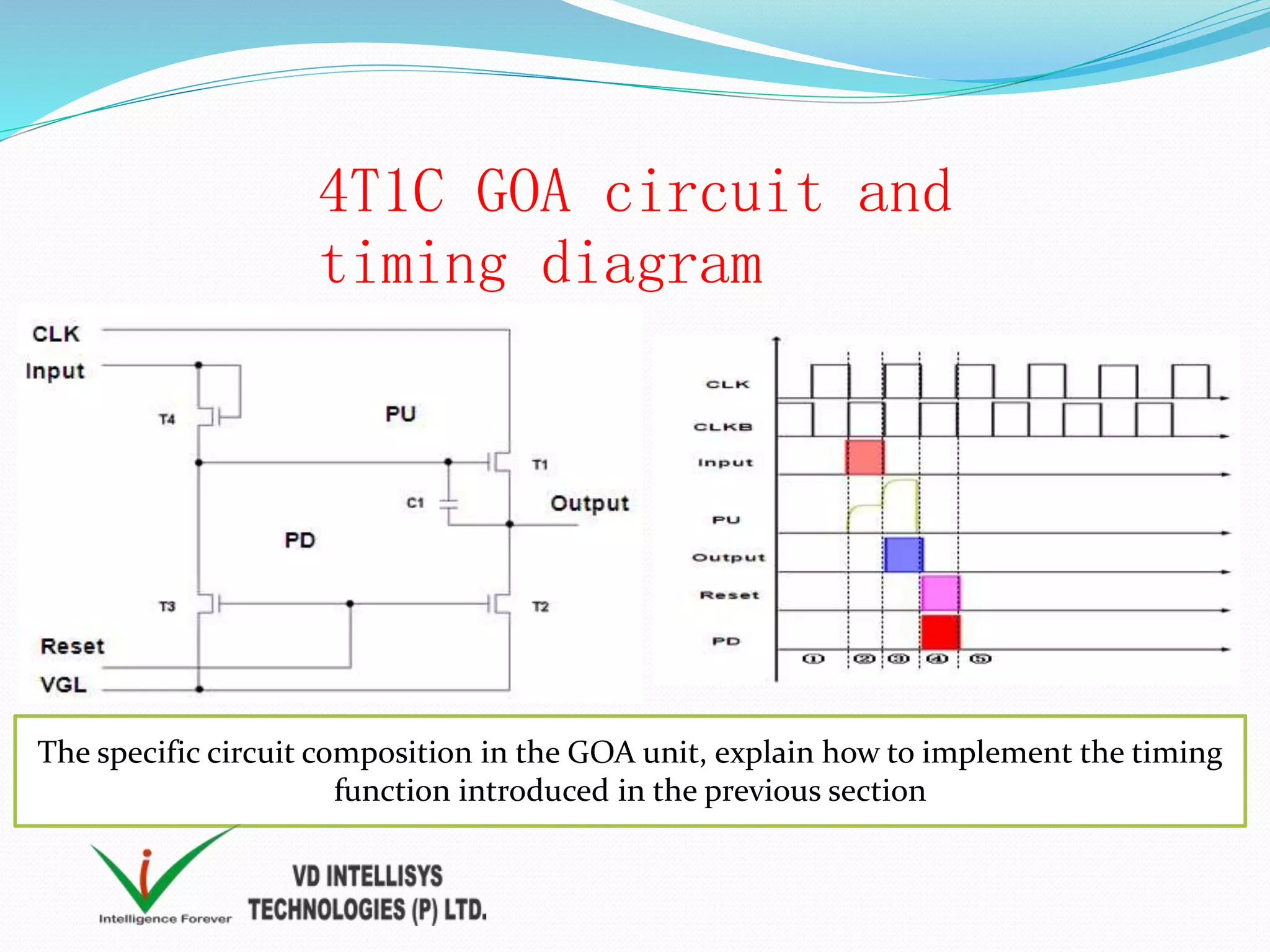

![ The working principle of 4T1C GOA unit circuit.

Step ①: No Input signal is input to the GOA unit, although the CLK voltage will appear

high, but because the PU point maintains a low voltage, TFT T1 is off, and GOA has no

output.

Step ②: Input signal (Generally, the Input of the GOA unit is Output[N-1], and the Input

of the GOA unit in the first row is STV) input through T4, make the PU point change to

high level, M3 is turned on, but at this time CLK is in Low level, so GOA still has no

output.

Step ③: CLK changes to high level. Since the PU point is already high, T1 is turned on

and Output will output high level. Due to the existence of capacitor C1 and the parasitic

capacitance of T1 itself, as the output potential rises High, the potential of the PU point

will be further raised, so that T1 will be turned on more, further improving the charging

capacity of T1 and ensuring pixel charging.

Step ④: CLK becomes low level, RESET becomes high level, PD point is raised, and T2

and T3 are turned on, PU point and Output are pulled low by VGL, and the output is

turned off.

Step ⑤: Return to the state of step ① and keep no output until the next frame is scanned.](https://image.slidesharecdn.com/lasermachinevd512etraining-201108091446/75/Laser-machine-vd512-e-training-46-2048.jpg)