LanzaTech aims to create a carbon smart future by capturing carbon-rich waste gases and converting them into liquid fuels and chemicals using proprietary microbes. Some key points:

- 65% of the remaining carbon budget that must stay in the ground has already been used up between 1870-2011, leaving only around 1000 gigatons of CO2 that can be emitted.

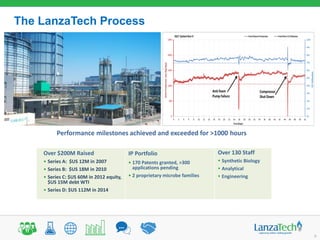

- The LanzaTech process uses novel gas fermentation technology to capture CO-rich gases from sources like steel mills and convert the carbon into products like ethanol, butanol, and other fuels/chemicals without using food crops.

- LanzaTech has successfully operated demonstration plants and pilots at various scales since 2008 to prove technical viability at