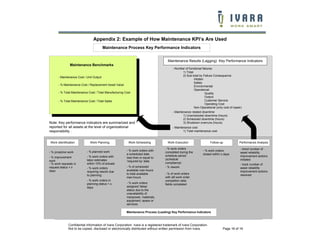

This document discusses key performance indicators (KPIs) for measuring maintenance performance. It begins by explaining how maintenance KPIs relate to but differ from manufacturing KPIs. It then presents the asset reliability process model, which contains 7 elements that define the maintenance function: business focus, work identification, planning, scheduling, execution, follow-up, and performance analysis.

The document recommends KPIs for each element of the asset reliability process model. For work identification, it suggests measuring the percentage of work requests addressed within 5 days and the percentage of available man-hours spent on proactive vs reactive work. For planning, it recommends measuring the percentage of planned work orders, percentage with estimated durations, and the accuracy of