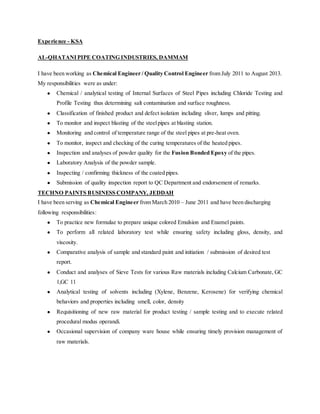

This document contains the resume of Khaliq ur Rehman, a chemical engineer from Pakistan. It summarizes his educational qualifications including an MSc in Chemical Engineering. It also outlines his work experience in quality control and production roles in Pakistan and Saudi Arabia over the past decade. His responsibilities have included quality inspection and testing, laboratory analysis, production management, and ensuring compliance with standards and procedures. Contact information is provided to allow potential employers to reach out to him.