Kermetico HVAF internal diameter spraying tungsten carbide hastelloy coatings

•

1 like•262 views

Thermal spray equipment to deposit 5 kg of tungsten carbide per hour, reaching a hardness of 950 HV300 in 3.75-4.0” internal diameters and over 1200 HV300 hardness in 4.5-5.0” internal diameters

Report

Share

Report

Share

Download to read offline

Recommended

Kermetico HVAF vs HVOF technology technical presentation

HVAF vs HVOF: high velocity thermal spray equipment to deposit metal and carbide coatings. Technological effectiveness basics, comparison of scientific data, Hardness, ductility, Young modulus, cavitation resistance.

hydro tubine HVOF coatings - spraymet Hydrokote

Nano HVOF coaitngs for Hydro turbine and under water components to resit silt erosion and cavitation

36877575 nano hvof-thermico-1-1

The document discusses Thermico's nanoHVOF coating system for demanding internal and external applications. Key points:

1. nanoHVOF uses a controlled plasma spherodization process to produce fine WC-CoCr powders (-5+2 μm or -10+5 μm) that form very dense, hard coatings when sprayed.

2. The system includes specialized powder feeders, torches optimized for fine powders, and process monitoring software to ensure coating quality.

3. nanoHVOF can coat internal diameters as small as 4" and produce near-net shaped coatings only ±15 μm thick for applications like turbine blades, pumps, and landing gear.

Spraymet oil and gas presentation

Spraymet started in 1995 with the aim of providing total surface technology solutions. It has various thermal spray facilities like HVOF and plasma spray systems. It offers services like thermal spraying, hardfacing, component manufacturing and surface treatment for industries like pumps, valves, steel etc. Spraymet has the capability to apply coatings like carbides, metals and alloys using thermal spray processes to improve properties like wear resistance, corrosion resistance, hardness etc. It has coated various industrial parts for applications in valves, pumps and other machinery.

Thermal spray acoustic emission monitoring

The document summarizes research on using acoustic emission (AE) monitoring to analyze the high velocity oxygen fuel (HVOF) thermal spraying process. Key points:

- AE monitoring can provide insights into particle impact behavior and phase changes during spraying and cooling, important for coating strength.

- A kinematic model was developed relating AE energy levels to particle kinetic energy based on spray parameters and slit geometry variables.

- AE signals were found to increase with coating buildup over multiple layers due to spray plume widening beyond the theoretical spot size.

How to calculate gate area require for hpdc die casting part

For Getting gate area we need to know:

1.Casting Volume after gate including Overflow

2.Average wall thickness

3.Cavity fill time

4.Allowed gate velocity

5. Flow Rate

Must watch this video you understand everything about getting the gate area in detail with Calculations.

Please also watch my old video in Die Casting Die Design Playlist.

https://youtu.be/WhnFeAvz6eU

When you like my videos please do not forget to subscribe

for Subscribe you simply need to click the link below;

https://www.youtube.com/channel/UCLsS...

Data of ceramic wear linings and lab

As a professional factory in China, we are manufacturing and exporting the below products since 1997.

1.92%,95%,T95%,99% Alumina ceramic tiles

2.ZTA(Zirconia Toughened Alumina) tiles/brick/block

3.Ceramic Rubber and Rubber-steel impact resistant linings

4.380/466/1000mm Cyclone for mining&mineral processing

5.Ceramic wearing compound for reparing

6.PU liner and PU products

Viscosity test 3

This document describes a test to determine the viscosity of bitumen. The test involves heating a sample to a specified temperature and measuring the time it takes for 50mL of the sample to flow through an orifice of a tar viscometer submerged in a water bath. Lower times indicate lower viscosity. The test is run at different temperatures depending on the type and grade of bitumen. Results provide the viscosity range for various common types and grades of bitumen to specify their fluidity properties.

Recommended

Kermetico HVAF vs HVOF technology technical presentation

HVAF vs HVOF: high velocity thermal spray equipment to deposit metal and carbide coatings. Technological effectiveness basics, comparison of scientific data, Hardness, ductility, Young modulus, cavitation resistance.

hydro tubine HVOF coatings - spraymet Hydrokote

Nano HVOF coaitngs for Hydro turbine and under water components to resit silt erosion and cavitation

36877575 nano hvof-thermico-1-1

The document discusses Thermico's nanoHVOF coating system for demanding internal and external applications. Key points:

1. nanoHVOF uses a controlled plasma spherodization process to produce fine WC-CoCr powders (-5+2 μm or -10+5 μm) that form very dense, hard coatings when sprayed.

2. The system includes specialized powder feeders, torches optimized for fine powders, and process monitoring software to ensure coating quality.

3. nanoHVOF can coat internal diameters as small as 4" and produce near-net shaped coatings only ±15 μm thick for applications like turbine blades, pumps, and landing gear.

Spraymet oil and gas presentation

Spraymet started in 1995 with the aim of providing total surface technology solutions. It has various thermal spray facilities like HVOF and plasma spray systems. It offers services like thermal spraying, hardfacing, component manufacturing and surface treatment for industries like pumps, valves, steel etc. Spraymet has the capability to apply coatings like carbides, metals and alloys using thermal spray processes to improve properties like wear resistance, corrosion resistance, hardness etc. It has coated various industrial parts for applications in valves, pumps and other machinery.

Thermal spray acoustic emission monitoring

The document summarizes research on using acoustic emission (AE) monitoring to analyze the high velocity oxygen fuel (HVOF) thermal spraying process. Key points:

- AE monitoring can provide insights into particle impact behavior and phase changes during spraying and cooling, important for coating strength.

- A kinematic model was developed relating AE energy levels to particle kinetic energy based on spray parameters and slit geometry variables.

- AE signals were found to increase with coating buildup over multiple layers due to spray plume widening beyond the theoretical spot size.

How to calculate gate area require for hpdc die casting part

For Getting gate area we need to know:

1.Casting Volume after gate including Overflow

2.Average wall thickness

3.Cavity fill time

4.Allowed gate velocity

5. Flow Rate

Must watch this video you understand everything about getting the gate area in detail with Calculations.

Please also watch my old video in Die Casting Die Design Playlist.

https://youtu.be/WhnFeAvz6eU

When you like my videos please do not forget to subscribe

for Subscribe you simply need to click the link below;

https://www.youtube.com/channel/UCLsS...

Data of ceramic wear linings and lab

As a professional factory in China, we are manufacturing and exporting the below products since 1997.

1.92%,95%,T95%,99% Alumina ceramic tiles

2.ZTA(Zirconia Toughened Alumina) tiles/brick/block

3.Ceramic Rubber and Rubber-steel impact resistant linings

4.380/466/1000mm Cyclone for mining&mineral processing

5.Ceramic wearing compound for reparing

6.PU liner and PU products

Viscosity test 3

This document describes a test to determine the viscosity of bitumen. The test involves heating a sample to a specified temperature and measuring the time it takes for 50mL of the sample to flow through an orifice of a tar viscometer submerged in a water bath. Lower times indicate lower viscosity. The test is run at different temperatures depending on the type and grade of bitumen. Results provide the viscosity range for various common types and grades of bitumen to specify their fluidity properties.

An introduction to steel piles

This document discusses the specifications and installation process for steel piles. It covers topics such as zone divisions of steel piles, welding procedures, surface preparation including blasting and painting, pile assembly, transport, positioning, and driving piles using a DELMAG hammer. The piles are fabricated in sections up to 12m in length, welded together, blasted and coated before being positioned and driven into place using a crane-mounted hammer to the required cutoff level as monitored by a surveyor.

Rotary drilling hose

Hebei Huayu Special Rubber Co., Ltd manufactures rotary drilling hoses in various grades from A to F. The hoses consist of an inner rubber tube, steel wire reinforcement layers, and an outer rubber cover. The tube and cover materials provide resistance to abrasion, corrosion, and other environmental factors. The steel wire reinforcement layers provide strength to withstand high pressures during oil and gas drilling operations. Hebei Huayu has an API 7K certificate and manufactures hoses in various sizes to meet customers' needs for pressure ranges from 15 MPa to 70 MPa depending on the hose grade.

Tap hole mass & castable for iron runner

ShengIron Refractories contribute on tap hole gun mud and castable for iron runner production & application.

Heat treatment presentation

The document describes the various processes involved in finishing heat treatment at a metallurgy laboratory, including furnaces, shot blasting, gate cutting, scarfing, heat treatment, hardness testing, painting, and quality certification. It provides details on the equipment used for each process such as the dimensions and capacities of furnaces, cut-off machines, and testing apparatus.

How to reduce hot forging costs through innovative techniques?

This presentation gives successful industrial case studies of cost reduction in hot forging by the use of:

1. Anti-scale protective coatings to prevent rejections due to scaling, reduce or eliminate shot blasting, reduce decarburization in heat treatment, hot rolling and hot forging.

2. Environment friendly die lubricants that eliminate pollution and increase die life.

3. Zero maintenance die lubricant spraying systems that ensure maximum uptime and no unplanned downtime during hot forging.

Case study AMPCOLOY® Nozcap

An exceptional weld spatter resistive antispatter material.

MIG welding nozzles made in AMPCOLOY® Nozcap have following benefits:

Very high resistance to weld spatters

steady supply of shielding gases due to no spatter

No need of additional plating

No need of anti-spatter gel or spray

Very easy to clean

Very less downtime for cleaning & maintenance purpose

High life of the Nozzle

group 4 ppt

This document discusses the development of an O-ring using peroxide curing of HNBR rubber. HNBR was chosen for its high saturation, good compression set and heat resistance. Di-cumyl peroxide was selected as the curing agent due to its high temperature stability. Samples with varying amounts of HNBR, carbon black, silica, zinc oxide and di-cumyl peroxide were prepared and tested. Sample E1 showed the best balance of properties including tensile strength, elongation, compression set and hardness, making it the selected final product. Further work may substitute FKM rubber and optimize carbon black particle size and amount.

Tundish making1

This document summarizes the process of preparing a tundish for continuous casting of steel. It discusses what a tundish is, the different lining layers including insulation, backup, and working linings. It details the steps to deskull, cool, and apply each lining layer. Key tundish furniture like the submerged entry nozzle and stopper are also described. The final steps of preheating the tundish and attached equipment before use in continuous casting are outlined.

CuNi hsc

Manufacturer of Copper Nickel Pipe, Fittings, Flanges, Sheet, Plate, Rod, Fastener, Valves, etc in UNS C70600 & C71500 Grade based in India

For Inquiries, mail to

jatinsanghvi9@gmail.com

Concrete Pumping & Placement Hose Products

JGB Enterprises is proud to present Eaglecrete Concrete Placement hoses and accessories. These material handling hoses and accessories are designed and manufactured to stand up to the most abrasive applications, and materials from sand, shot, dry cement, gravel, seed, lime, animal feed, and even mild chemicals, agricultural sprays, and hot air. JGB's Eaglecrete® Concrete Pumping Hose comes in 1233 or 1300 psi working pressures. It is constructed with a black conductive natural rubber tube and NR/NBR blend cover. The Eaglecrete® 1233 is reinforced with spiral textile while the Eaglecrete® 1300 is reinforced with a spiral wire. Heavy-Duty, Victaulic, NPT and Metric coupling configurations are available with this hose. JGB Enterprises Eagle FlexCrete is a new alternative in the concrete placement industry. The Eagle FlexCrete answers an industry need for a concrete placement hose that handles easily while placing ICF forms as well as tall walls and columns where space is limited. The Eagle FlexCrete’s lay flat construction allows better flow control & lower placement rates than standard boom tip hoses. Contact our Sales Department for more Info at 315-451-2770

236-nicht-metallisch-en-150204-web

Körting provides non-metallic vacuum systems made of materials like graphite and PTFE that are resistant to corrosion from acids and bases. These materials allow the systems to be used in applications where metals would be damaged. Graphite systems in particular can operate from -60°C to +180°C and from -1 to +6 bar, with some cases to +200°C and 10 bar. Körting tests the systems before delivery to ensure leak-proof performance and quality.

Taphole clay for blast furnace operation

This document discusses taphole clay and blast furnace operation from Sheng Iron Refractories. It covers three parts: (1) the importance of proper tapping times to safely remove molten iron and slag, (2) operation notices to maintain a safe taphole, including fully draining before plugging and avoiding humidity, and (3) factors to consider when choosing a quality taphole clay product, such as long stable taphole length and minimization of spraying during operation.

Repairing of kiln shell crack

1. Ankit Metals & Power Limited operates a sponge iron plant with two 350 TPD rotary kilns. One of the kilns developed cracks in the shell measuring up to 2000mm long and 25mm deep.

2. EWAC Alloys recommended welding the cracks with CPHFD 011 welding alloy. The cracks were welded from the outside in a double V groove technique with 3.15mm root passes and 4mm final layers.

3. After welding, testing confirmed the cracks were fully repaired with no remaining defects. Proper techniques like preheating, minimum current, and controlled cooling were followed to ensure a quality repair.

Product Guide

The document provides information on Utilcell, a leading manufacturer of load cells, mounting accessories, and weighing indicators. It operates globally with headquarters in Barcelona and local offices in several countries. The document includes specifications and applications for Utilcell's various load cell product lines for different capacities and environments.

Toolox steel mill applications

This is a presentation that was created for a Toolox information day. Tool is a tool steel that can be flame cut into steel profiles. The present

Tube-Caron_Brochure-Specifications_ENG

Tube Caron Inc. is a precision tubing bending company that has specialized in thin-walled tubing since 1987. They work with materials like aluminized steel, stainless steel, aluminum and copper in tubing diameters from 3/8" to 6". Their engineering team works to optimize manufacturing processes to maintain high quality standards and affordable pricing for clients. The document provides detailed specifications on available tubing materials, bending radii, tolerances and other production standards.

Kingcera company profile 20190916

Hunan Kingcera Engineering Co.,Ltd is an manufacturer of Al2O3 alumina ceramic wear resistant material, like ZTA ceramic liner, ceramic lined elbow, ceramic lined sleeve, ceramic lined chute, ceramic lined hopper. We provide the service for 4 main minings in Australia, such as FMG, Roy Hill, Rio Tinto, BHP.

Please contact us via info@kingcera.com to get more details.

Kluberlub be-41-542 Mr Tùng - 0987 988 407 | www.khodaumo.com

This document provides information on Kl berlub BE 41- 542, a heavy-duty grease for highly loaded rolling bearings. It is based on mineral oil with lithium soap and additives that provide excellent wear protection, water resistance, and adhesion. It is suitable for applications with service temperatures up to 140°C, including load rollers, crane wheels, hammer mills, and rolling bearings under shock or pulsating stress. Test results show it provides a service life over 100 hours on rolling bearings and low rolling element and cage wear.

Spraymet special process matrix

This document provides a list and comparison of various surface improvement and modification processes used for applications in the oil and gas industry requiring resistance to metal-to-metal wear, abrasive wear, corrosion, and cavitation. Seven processes are described including liquid nitriding, gas nitriding, spray and fuse hard facing, high velocity oxy fuel spraying, hot wire tungsten inert gas cladding, laser cladding, and physical vapor deposition coating. Each process is summarized with main characteristics, advantages, limitations, and example alloy compatibilities and applications.

End splitting during long products rolling billet quality of rolling process

End splitting occurs because the material being rolled has not enough ductility to withstand the stress to which it is submitted. This may happens for different reasons. Coarse cracks in the billet end, like central or diagonal cracks, weakens the end, particularly when the plane where are located coincides in part with the symmetry plane between rolls. Hot ductility of steel depends on the one hand of their intrinsic features, and on the other hand, on the temperature at which they suffer the stress, and its speed.

It is important to roll the steel within the range of higher ductility at a given deformation speed. This is more critical for steels with inherent low ductility as those containing high sulfur.

The role of MnS stringers is also clear; having S controlled at the lower level of the specification is favorable. Nevertheless it is worth to mention that if caster condition is proper and excessive thermal/mechanical stresses do not arise, very high Mn/S ratio is not necessary.

Bar ends loss temperature faster. Another factor is roll cooling, it has to be correctly oriented, not excessive and keeping the position along the processing time.

In other factors experimental and modeling results are apparently controversial. There is coincidence in the fact that more friction between bar and rolls promotes splitting, but not in factors like roll diameter and reduction.

On the basis of pilot rolling results, plane, box-box, square to round and oval to round passes are favorable to avoid splitting, while oval to square promotes splitting.

SMART MANUFACTURING METHOD FOR PISTON ROD CHROME PLATING

This document compares the traditional hard chrome plating process for piston rods to a newer HVOF (High Velocity Oxy Fuel) process. Hard chrome plating is commonly used due to its durability and corrosion resistance, but contains toxic hexavalent chromium. HVOF offers superior performance and is more environmentally friendly. Testing showed HVOF coatings had higher hardness and better corrosion resistance than hard chrome coatings. HVOF also has fewer processing steps and does not release harmful emissions, making it a smarter manufacturing method for piston rod coating.

Yiheng

The API casing is generally used for the borehole wall support in the drilling as well as after the completion of a well, so as to make sure the smooth running of the drilling process and also the normal procedure of the whole oil well after well completion. As a result of the advancement in recent years, making use of the product is much more substantial. It is generally utilized in oil, gas, coal bed methane, water system, thermal electrical power generation, hydropower penstock, thermal electrical power generation, dredging design, as well as other sectors.

More Related Content

What's hot

An introduction to steel piles

This document discusses the specifications and installation process for steel piles. It covers topics such as zone divisions of steel piles, welding procedures, surface preparation including blasting and painting, pile assembly, transport, positioning, and driving piles using a DELMAG hammer. The piles are fabricated in sections up to 12m in length, welded together, blasted and coated before being positioned and driven into place using a crane-mounted hammer to the required cutoff level as monitored by a surveyor.

Rotary drilling hose

Hebei Huayu Special Rubber Co., Ltd manufactures rotary drilling hoses in various grades from A to F. The hoses consist of an inner rubber tube, steel wire reinforcement layers, and an outer rubber cover. The tube and cover materials provide resistance to abrasion, corrosion, and other environmental factors. The steel wire reinforcement layers provide strength to withstand high pressures during oil and gas drilling operations. Hebei Huayu has an API 7K certificate and manufactures hoses in various sizes to meet customers' needs for pressure ranges from 15 MPa to 70 MPa depending on the hose grade.

Tap hole mass & castable for iron runner

ShengIron Refractories contribute on tap hole gun mud and castable for iron runner production & application.

Heat treatment presentation

The document describes the various processes involved in finishing heat treatment at a metallurgy laboratory, including furnaces, shot blasting, gate cutting, scarfing, heat treatment, hardness testing, painting, and quality certification. It provides details on the equipment used for each process such as the dimensions and capacities of furnaces, cut-off machines, and testing apparatus.

How to reduce hot forging costs through innovative techniques?

This presentation gives successful industrial case studies of cost reduction in hot forging by the use of:

1. Anti-scale protective coatings to prevent rejections due to scaling, reduce or eliminate shot blasting, reduce decarburization in heat treatment, hot rolling and hot forging.

2. Environment friendly die lubricants that eliminate pollution and increase die life.

3. Zero maintenance die lubricant spraying systems that ensure maximum uptime and no unplanned downtime during hot forging.

Case study AMPCOLOY® Nozcap

An exceptional weld spatter resistive antispatter material.

MIG welding nozzles made in AMPCOLOY® Nozcap have following benefits:

Very high resistance to weld spatters

steady supply of shielding gases due to no spatter

No need of additional plating

No need of anti-spatter gel or spray

Very easy to clean

Very less downtime for cleaning & maintenance purpose

High life of the Nozzle

group 4 ppt

This document discusses the development of an O-ring using peroxide curing of HNBR rubber. HNBR was chosen for its high saturation, good compression set and heat resistance. Di-cumyl peroxide was selected as the curing agent due to its high temperature stability. Samples with varying amounts of HNBR, carbon black, silica, zinc oxide and di-cumyl peroxide were prepared and tested. Sample E1 showed the best balance of properties including tensile strength, elongation, compression set and hardness, making it the selected final product. Further work may substitute FKM rubber and optimize carbon black particle size and amount.

Tundish making1

This document summarizes the process of preparing a tundish for continuous casting of steel. It discusses what a tundish is, the different lining layers including insulation, backup, and working linings. It details the steps to deskull, cool, and apply each lining layer. Key tundish furniture like the submerged entry nozzle and stopper are also described. The final steps of preheating the tundish and attached equipment before use in continuous casting are outlined.

CuNi hsc

Manufacturer of Copper Nickel Pipe, Fittings, Flanges, Sheet, Plate, Rod, Fastener, Valves, etc in UNS C70600 & C71500 Grade based in India

For Inquiries, mail to

jatinsanghvi9@gmail.com

Concrete Pumping & Placement Hose Products

JGB Enterprises is proud to present Eaglecrete Concrete Placement hoses and accessories. These material handling hoses and accessories are designed and manufactured to stand up to the most abrasive applications, and materials from sand, shot, dry cement, gravel, seed, lime, animal feed, and even mild chemicals, agricultural sprays, and hot air. JGB's Eaglecrete® Concrete Pumping Hose comes in 1233 or 1300 psi working pressures. It is constructed with a black conductive natural rubber tube and NR/NBR blend cover. The Eaglecrete® 1233 is reinforced with spiral textile while the Eaglecrete® 1300 is reinforced with a spiral wire. Heavy-Duty, Victaulic, NPT and Metric coupling configurations are available with this hose. JGB Enterprises Eagle FlexCrete is a new alternative in the concrete placement industry. The Eagle FlexCrete answers an industry need for a concrete placement hose that handles easily while placing ICF forms as well as tall walls and columns where space is limited. The Eagle FlexCrete’s lay flat construction allows better flow control & lower placement rates than standard boom tip hoses. Contact our Sales Department for more Info at 315-451-2770

236-nicht-metallisch-en-150204-web

Körting provides non-metallic vacuum systems made of materials like graphite and PTFE that are resistant to corrosion from acids and bases. These materials allow the systems to be used in applications where metals would be damaged. Graphite systems in particular can operate from -60°C to +180°C and from -1 to +6 bar, with some cases to +200°C and 10 bar. Körting tests the systems before delivery to ensure leak-proof performance and quality.

Taphole clay for blast furnace operation

This document discusses taphole clay and blast furnace operation from Sheng Iron Refractories. It covers three parts: (1) the importance of proper tapping times to safely remove molten iron and slag, (2) operation notices to maintain a safe taphole, including fully draining before plugging and avoiding humidity, and (3) factors to consider when choosing a quality taphole clay product, such as long stable taphole length and minimization of spraying during operation.

Repairing of kiln shell crack

1. Ankit Metals & Power Limited operates a sponge iron plant with two 350 TPD rotary kilns. One of the kilns developed cracks in the shell measuring up to 2000mm long and 25mm deep.

2. EWAC Alloys recommended welding the cracks with CPHFD 011 welding alloy. The cracks were welded from the outside in a double V groove technique with 3.15mm root passes and 4mm final layers.

3. After welding, testing confirmed the cracks were fully repaired with no remaining defects. Proper techniques like preheating, minimum current, and controlled cooling were followed to ensure a quality repair.

Product Guide

The document provides information on Utilcell, a leading manufacturer of load cells, mounting accessories, and weighing indicators. It operates globally with headquarters in Barcelona and local offices in several countries. The document includes specifications and applications for Utilcell's various load cell product lines for different capacities and environments.

Toolox steel mill applications

This is a presentation that was created for a Toolox information day. Tool is a tool steel that can be flame cut into steel profiles. The present

Tube-Caron_Brochure-Specifications_ENG

Tube Caron Inc. is a precision tubing bending company that has specialized in thin-walled tubing since 1987. They work with materials like aluminized steel, stainless steel, aluminum and copper in tubing diameters from 3/8" to 6". Their engineering team works to optimize manufacturing processes to maintain high quality standards and affordable pricing for clients. The document provides detailed specifications on available tubing materials, bending radii, tolerances and other production standards.

Kingcera company profile 20190916

Hunan Kingcera Engineering Co.,Ltd is an manufacturer of Al2O3 alumina ceramic wear resistant material, like ZTA ceramic liner, ceramic lined elbow, ceramic lined sleeve, ceramic lined chute, ceramic lined hopper. We provide the service for 4 main minings in Australia, such as FMG, Roy Hill, Rio Tinto, BHP.

Please contact us via info@kingcera.com to get more details.

Kluberlub be-41-542 Mr Tùng - 0987 988 407 | www.khodaumo.com

This document provides information on Kl berlub BE 41- 542, a heavy-duty grease for highly loaded rolling bearings. It is based on mineral oil with lithium soap and additives that provide excellent wear protection, water resistance, and adhesion. It is suitable for applications with service temperatures up to 140°C, including load rollers, crane wheels, hammer mills, and rolling bearings under shock or pulsating stress. Test results show it provides a service life over 100 hours on rolling bearings and low rolling element and cage wear.

Spraymet special process matrix

This document provides a list and comparison of various surface improvement and modification processes used for applications in the oil and gas industry requiring resistance to metal-to-metal wear, abrasive wear, corrosion, and cavitation. Seven processes are described including liquid nitriding, gas nitriding, spray and fuse hard facing, high velocity oxy fuel spraying, hot wire tungsten inert gas cladding, laser cladding, and physical vapor deposition coating. Each process is summarized with main characteristics, advantages, limitations, and example alloy compatibilities and applications.

End splitting during long products rolling billet quality of rolling process

End splitting occurs because the material being rolled has not enough ductility to withstand the stress to which it is submitted. This may happens for different reasons. Coarse cracks in the billet end, like central or diagonal cracks, weakens the end, particularly when the plane where are located coincides in part with the symmetry plane between rolls. Hot ductility of steel depends on the one hand of their intrinsic features, and on the other hand, on the temperature at which they suffer the stress, and its speed.

It is important to roll the steel within the range of higher ductility at a given deformation speed. This is more critical for steels with inherent low ductility as those containing high sulfur.

The role of MnS stringers is also clear; having S controlled at the lower level of the specification is favorable. Nevertheless it is worth to mention that if caster condition is proper and excessive thermal/mechanical stresses do not arise, very high Mn/S ratio is not necessary.

Bar ends loss temperature faster. Another factor is roll cooling, it has to be correctly oriented, not excessive and keeping the position along the processing time.

In other factors experimental and modeling results are apparently controversial. There is coincidence in the fact that more friction between bar and rolls promotes splitting, but not in factors like roll diameter and reduction.

On the basis of pilot rolling results, plane, box-box, square to round and oval to round passes are favorable to avoid splitting, while oval to square promotes splitting.

What's hot (20)

How to reduce hot forging costs through innovative techniques?

How to reduce hot forging costs through innovative techniques?

Kluberlub be-41-542 Mr Tùng - 0987 988 407 | www.khodaumo.com

Kluberlub be-41-542 Mr Tùng - 0987 988 407 | www.khodaumo.com

End splitting during long products rolling billet quality of rolling process

End splitting during long products rolling billet quality of rolling process

Similar to Kermetico HVAF internal diameter spraying tungsten carbide hastelloy coatings

SMART MANUFACTURING METHOD FOR PISTON ROD CHROME PLATING

This document compares the traditional hard chrome plating process for piston rods to a newer HVOF (High Velocity Oxy Fuel) process. Hard chrome plating is commonly used due to its durability and corrosion resistance, but contains toxic hexavalent chromium. HVOF offers superior performance and is more environmentally friendly. Testing showed HVOF coatings had higher hardness and better corrosion resistance than hard chrome coatings. HVOF also has fewer processing steps and does not release harmful emissions, making it a smarter manufacturing method for piston rod coating.

Yiheng

The API casing is generally used for the borehole wall support in the drilling as well as after the completion of a well, so as to make sure the smooth running of the drilling process and also the normal procedure of the whole oil well after well completion. As a result of the advancement in recent years, making use of the product is much more substantial. It is generally utilized in oil, gas, coal bed methane, water system, thermal electrical power generation, hydropower penstock, thermal electrical power generation, dredging design, as well as other sectors.

Pneumatic Actuators For Industrial Valves

Hytork® develops and manufacturers actuators for the automation of industrial valves. Product range includes pneumatic actuators and a wide range of control accessories. Product development is based on modular construction that allows for fast delivery from stock components and easy upgrade to control units as well as quick and efficient modification and repair.

Investment Casting FAQ

Investment casting is a manufacturing process that involves creating wax replicas of parts, surrounding them in ceramic shells, melting out the wax, and pouring molten metal into the shells. It allows for the production of complex, near-net shape metal parts. Investment castings can be made in a variety of alloys and sizes, from small dental braces to large aircraft engine components. The process provides excellent surface finishes and tight tolerances, reducing machining needs. While tooling costs are higher than other casting methods, investment casting is often more cost effective due to reduced post-casting machining.

Presentacion exco (ingles) dec 19 11

EXCO COLOMBIANA S.A. is a Colombian tube manufacturing company with facilities covering 75,400 square feet. It was originally established as a branch of the American steel company ARMCO Inc. EXCO offers a wide range of value-added tubular solutions including cutting, bending, punching, welding, and powder coating of mechanical steel tubes. Their goal is to develop customers through customized tubular products and achieve high satisfaction levels.

Surface update

This document provides information on Caterpillar's CEMA C, D and E series surface conveyor structure products. It describes the various carrying idlers, steel rolls, EXALON polyethylene rolls, rubber disc return idlers, and electronic quality tracking systems that are designed to transport bulk materials reliably in different applications. The document also notes that all products conform to CEMA standards and are intended to provide long life, high reliability, and superior performance.

DRILLING ACCESSORIES | PRD RIGS INDIA | DRILLING RIGS

DRILLING ACCESSORIES - PRD RIGS INDIA

We manufacture DTH Hammers in different sizes ranging from 3″ to 18″.These hammers are made corresponding to Drilling Hammers to carry out prevalent objectives. These hammers are used in various down the hole operations like bench drilling, foundation drilling, underground production drilling (mining), exploration and civil engineering applications (water well drilling) and many more.

DTH Hammers are available in valve-less model and is competent to operate in harsh conditions. These hammers are conserves energy and offers low cost maintenance. It is extensively used in various sectors owing to its uncomplicated and convenient re-assembly and dis-assembly operations.

We also produce Bits that are sturdy heavy duty tools with simple design.They are designed for maximum performance and for easy maintenance at a minimum cost. Our Bits provide more cutting power and faster rates with heat treatment and tight controlled machining tolerances. Our Bits are available in various models and designs as per the industrial applications.

Our Pole Drill Hammers and Bits are ideally made of superior quality raw material, with an inbuilt characteristic of performing with precision in their specified application. They are long lasting, durable and easily maintainable.

Diesel locomotive workshop

The document summarizes the work done at the Diesel Locomotive Works in Varanasi, India. It describes the various workshops that manufacture and assemble parts for diesel locomotives, including the heavy welding shop, heavy machine shop, rotor shop, and paint shop. The heavy welding shop performs various arc welding techniques to join metal parts. The heavy machine shop uses machines like lathes and CNC to cut and shape metal parts. The rotor shop focuses on manufacturing and assembling turbochargers that provide fresh air to the locomotive engines. After assembly, the locomotive parts are sent to the paint shop for final painting and markings.

MICROSTRUCTURAL CHARACTERIZATION AND HOT EROSION BEHAVIOR OF CRC-NICR COATED ...

Erosion behavior of the High Velocity Oxygen Fuel (HVOF) deposited CrC - NiCr coating on stainless steel was evaluated. Th e solid particle erosion stu dy was conducted using an air jet erosion test rig at a velocity 60m/sec and impingement angle 60 ° , 75 ° and 90 ° , on HVOF spray coated steel at 600 ° C. Microstructure, chemical composition, phases present in the coating on the steel substrate was studied by using Scanning Electron Microscope (SEM) and X - Ray Diffraction method. The Hardness is gradually increasing with increasing content of Cr 3 C 2 particles in all three samples. The erosion mechanism of coatings was also discussed and erosion rate is maximum at impingement angle 75 °

PPE Demo Report by Tuan Afaham Burah

This document provides a demo report for stainless steel finishing tools and accessories from Inox for a proposed stainless steel workshop. It details 5 steps for removing and smoothing a fillet weld using various grinding, polishing, and cleaning tools. It also proposes other machines for the workshop and provides information on factors that influence stainless steel finishing like grade, environment, abrasives used, and machine speed. Proper procedure and use of carbon-free abrasives are emphasized for obtaining the desired mirror polish finish without discoloration.

Improved Material and Enhanced Fatigue Resistance for Gear Components

Abstract

This paper shows the latest progress in steel grades and in case hardening technology for gear components.

To answer the demand for fuel-efficient vehicles, modern gear boxes are built much lighter. Improving fatigue resistance is a key factor to allow for the design of thin components to be used in advanced vehicle transmissions. The choice of material and the applied heat treat process are of key importance to enhance the fatigue resistance of gear components.

By applying the technology of Low Pressure Carburizing (LPC) and High Pressure Gas Quenching (HPGQ), the tooth root bending strength can be significantly enhanced, compared to traditional heat treatment with atmospheric carburizing and oil quenching.

Besides heat treatment, significant progress has been made over the past years on the steels being used for gear components. The hardenability of case hardening steels such as 5130H, 5120H, 20MnCr5, 27MnCr5, 18CrNiMo7-6 etc. has been stepwise increased in recent years. An important factor for fatigue resistance is the grain size after heat treatment. Therefore, grain size control is a key goal when developing new modifications of steel grades.

After enhancing grain size control, it was possible to increase the carburizing temperatures over the past years from 930°C to 980°C (1700°F to 1800°F) which resulted in shorter heat treatment cycles and thus in significant cost savings.

With the introduction of new microalloyed steels for grain size stability, carburizing temperatures can now be even further increased to temperatures of up to 1050°C (1920°F), leading to even more economic process cycles. By adding microelements such as Niobium or Titanium in the ppm-range, nitride and carbonitride-precipitates are formed. These precipitates effectively limit the grain-growth during the heat treatment process.

Bc_Aero_Fold_Out_2016_08

Bodycote provides coating solutions for the aerospace and defense industries to improve components' resistance to wear, corrosion, and extreme operating environments. For over 30 years, leading aerospace companies have trusted Bodycote to apply thermal spray, ceramic, and carbide coatings to critical components. Bodycote's international network of facilities holds numerous quality certifications and coatings are tested to meet stringent industry standards.

Spindle Repair & Rebuilding Services

Good spindle repair can make all the difference in the lifespan and productivity of your machine. Learn the ins and outs of repairing spindles.

Flexsil - AMETEK FPP

Flexsil®, the industry-leading refractory cloth filter material, is recognized as the premier filter cloth solution

Air Mac Blower Pkgs Literature

Airmac provides premium blower packages through innovative design and superior construction. They offer a range of blower, motor, and package options to suit various applications. Airmac was founded on principles of quality and innovation, and has 20 years of experience supplying blower packages internationally.

Service and Technologies for Process Industries

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, helps plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of products has you covered.

LACS Ceramic Coating Presentation (Shared File)

Louisiana Advanced Coating Solutions provides proprietary ceramic coatings for industrial, automotive, aerospace, military, and other applications. Their coatings offer benefits such as corrosion and heat resistance from 500°F to over 2000°F, various thickness and color options, and increased performance and lifespan of coated parts and equipment. Key products include heat cured, high temperature, dry film lubricant, clear, heat dissipating, and NIR coatings. The company conducts thorough testing of coatings' durability, corrosion protection, hardness, flexibility, chemical resistance, adhesion, abrasion resistance, and thermal barrier properties per ASTM standards. Ceramic coatings can significantly increase equipment lifespan through reduced wear and maintenance needs.

AdvInMetallography.pptx

1) Advances in metallographic techniques such as minimum area of contact cutting (MACC) and orbital cutting produce less damage to specimens during sectioning compared to traditional chop cutters.

2) Orbital cutting maintains a more constant pressure on the specimen compared to chop cutting, which varies pressure and increases heat generation.

3) Precision saws such as the IsoMet series provide versatility and optional features, allowing precise sectioning with minimal damage. Proper mounting and grinding/polishing techniques further minimize artifacts.

Corrosion? No thanks...

The document describes the various steel treatment and painting processes used on Atlas Copco generators and light towers to protect them from corrosion when exposed to outdoor environments. Different components receive different treatments based on their exposure and importance. All steel components receive a galvanization treatment before further treatments and painting. The canopy receives powder coating, while critical components and the base frame undergo nitrogen laser cutting and cataphoresis before final painting. These treatments help provide long-term corrosion protection and extend the life of components.

Wagon project report mechanical vocational training presentation haxxo24 i~i

This document provides details about the manufacturing process of a BCNHL wagon at Modern Industries. It discusses the standard features of a BCNHL wagon and describes the key parts that make up the wagon including the underframe, center sill, body end, body side, roof, door, wheels and bogie, and braking system. It then outlines the main steps in the manufacturing process, which includes cutting, pressing, welding, assembly of parts, shot blasting, and quality checks. Various welding techniques used like arc welding and MIG welding are also summarized.

Similar to Kermetico HVAF internal diameter spraying tungsten carbide hastelloy coatings (20)

SMART MANUFACTURING METHOD FOR PISTON ROD CHROME PLATING

SMART MANUFACTURING METHOD FOR PISTON ROD CHROME PLATING

DRILLING ACCESSORIES | PRD RIGS INDIA | DRILLING RIGS

DRILLING ACCESSORIES | PRD RIGS INDIA | DRILLING RIGS

MICROSTRUCTURAL CHARACTERIZATION AND HOT EROSION BEHAVIOR OF CRC-NICR COATED ...

MICROSTRUCTURAL CHARACTERIZATION AND HOT EROSION BEHAVIOR OF CRC-NICR COATED ...

Improved Material and Enhanced Fatigue Resistance for Gear Components

Improved Material and Enhanced Fatigue Resistance for Gear Components

Wagon project report mechanical vocational training presentation haxxo24 i~i

Wagon project report mechanical vocational training presentation haxxo24 i~i

Recently uploaded

按照学校原版(UST文凭证书)圣托马斯大学毕业证快速办理

精仿办理本科毕业证【微信:176555708】【(UST毕业证书)圣托马斯大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

一比一原版(UCSB毕业证)圣塔芭芭拉社区大学毕业证如何办理

UCSB毕业证文凭证书【微信95270640】☀《圣塔芭芭拉社区大学毕业证购买》Q微信95270640《UCSB毕业证可查真实》文凭、本科、硕士、研究生学历都可以做,留信认证的作用:

1:该专业认证可证明留学生真实留学身份。

2:同时对留学生所学专业等级给予评定。

3:国家专业人才认证中心颁发入库证书

4:这个入网证书并且可以归档到地方

5:凡是获得留信网入网的信息将会逐步更新到个人身份内,将在网内查询个人身份证信息后,同步读取人才网入库信息。

6:个人职称评审加20分。

7:个人信誉贷款加10分。

8:在国家人才网主办的全国网络招聘大会中纳入资料,供国家500强等高端企业选择人才《文凭UCSB毕业证书原版制作UCSB成绩单》仿制UCSB毕业证成绩单圣塔芭芭拉社区大学学位证书pdf电子图》。

如果您是以下情况,我们都能竭诚为您解决实际问题:【公司采用定金+余款的付款流程,以最大化保障您的利益,让您放心无忧】

1、在校期间,因各种原因未能顺利毕业,拿不到官方毕业证+微信95270640

2、面对父母的压力,希望尽快拿到圣塔芭芭拉社区大学圣塔芭芭拉社区大学本科毕业证成绩单;

3、不清楚流程以及材料该如何准备圣塔芭芭拉社区大学圣塔芭芭拉社区大学本科毕业证成绩单;

4、回国时间很长,忘记办理;

5、回国马上就要找工作,办给用人单位看;

6、企事业单位必须要求办理的;

面向美国乔治城大学毕业留学生提供以下服务:

【★圣塔芭芭拉社区大学圣塔芭芭拉社区大学本科毕业证成绩单毕业证、成绩单等全套材料,从防伪到印刷,从水印到钢印烫金,与学校100%相同】

【★真实使馆认证(留学人员回国证明),使馆存档可通过大使馆查询确认】

【★真实教育部认证,教育部存档,教育部留服网站可查】

【★真实留信认证,留信网入库存档,可查圣塔芭芭拉社区大学圣塔芭芭拉社区大学本科毕业证成绩单】

我们从事工作十余年的有着丰富经验的业务顾问,熟悉海外各国大学的学制及教育体系,并且以挂科生解决毕业材料不全问题为基础,为客户量身定制1对1方案,未能毕业的回国留学生成功搭建回国顺利发展所需的桥梁。我们一直努力以高品质的教育为起点,以诚信、专业、高效、创新作为一切的行动宗旨,始终把“诚信为主、质量为本、客户第一”作为我们全部工作的出发点和归宿点。同时为海内外留学生提供大学毕业证购买、补办成绩单及各类分数修改等服务;归国认证方面,提供《留信网入库》申请、《国外学历学位认证》申请以及真实学籍办理等服务,帮助众多莘莘学子实现了一个又一个梦想。

专业服务,请勿犹豫联系我

如果您真实毕业回国,对于学历认证无从下手,请联系我,我们免费帮您递交

诚招代理:本公司诚聘当地代理人员,如果你有业余时间,或者你有同学朋友需要,有兴趣就请联系我

你赢我赢,共创双赢

你做代理,可以帮助圣塔芭芭拉社区大学同学朋友

你做代理,可以拯救圣塔芭芭拉社区大学失足青年

你做代理,可以挽救圣塔芭芭拉社区大学一个个人才

你做代理,你将是别人人生圣塔芭芭拉社区大学的转折点

你做代理,可以改变自己,改变他人,给他人和自己一个机会娃于是天天扳着手指算计着读书也格外刻苦无奈时间总过得太慢太慢每次父亲往家打电话山娃总抢着接听一个劲地提醒父亲别忘了正月说的话电话那头总会传来父亲嘿嘿的笑连连说记得记得但别忘了拿奖状进城啊考试一结束山娃就迫不及待地给父亲挂电话:爸我拿奖了三好学生接我进城吧父亲果然没有食言第二天就请假回家接山娃离开爷爷奶奶的那一刻山娃又伤心得泪如雨下宛如军人奔赴前线般难舍和悲壮卧空调大巴挤长蛇列车山娃发现车上挤满了乡

加急办理美国南加州大学毕业证文凭毕业证原版一模一样

原版一模一样【微信:741003700 】【美国南加州大学毕业证文凭】【微信:741003700 】学位证,留信认证(真实可查,永久存档)offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原海外各大学 Bachelor Diploma degree, Master Degree Diploma

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微741003700

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

一比一原版(Greenwich文凭证书)格林威治大学毕业证如何办理

毕业原版【微信:176555708】【(Greenwich毕业证书)格林威治大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

按照学校原版(UVic文凭证书)维多利亚大学毕业证快速办理

不能毕业办理文凭'毕业证购买'【微信:176555708】【(UVic毕业证书)维多利亚大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

按照学校原版(AU文凭证书)英国阿伯丁大学毕业证快速办理

出售毕业典礼【微信:176555708】【(AU毕业证书)英国阿伯丁大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

按照学校原版(UAL文凭证书)伦敦艺术大学毕业证快速办理

出售假学位证【微信:176555708】【(UAL毕业证书)伦敦艺术大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

按照学校原版(Adelaide文凭证书)阿德莱德大学毕业证快速办理

怎样办理复制【微信:176555708】【(Adelaide毕业证书)阿德莱德大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

一比一原版(UMich毕业证)密歇根大学|安娜堡分校毕业证如何办理

UMich硕士学位证成绩单【微信95270640】做UMich文凭、办UMich文凭、买UMich文凭Q微信95270640买办国外文凭UMich毕业证买学历咨询/代办美国毕业证成绩单文凭、办澳洲文凭毕业证、办加拿大大学毕业证文凭英国毕业证学历认证-毕业证文凭成绩单、假文凭假毕业证假学历书制作仿制、改成绩、教育部学历学位认证、毕业证、成绩单、文 凭、UMich学历文凭、UMich假学位证书、毕业证文凭、、文凭毕业证、毕业证认证、留服认证、使馆认证、使馆证明 、使馆留学回国人员证明、留学生认证、学历认证、文凭认证、学位认证

[留学文凭学历认证(留信认证使馆认证)密歇根大学|安娜堡分校毕业证成绩单毕业证证书大学Offer请假条成绩单语言证书国际回国人员证明高仿教育部认证申请学校等一切高仿或者真实可查认证服务。

多年留学服务公司,拥有海外样板无数能完美1:1还原海外各国大学degreeDiplomaTranscripts等毕业材料。海外大学毕业材料都有哪些工艺呢?工艺难度主要由:烫金.钢印.底纹.水印.防伪光标.热敏防伪等等组成。而且我们每天都在更新海外文凭的样板以求所有同学都能享受到完美的品质服务。

国外毕业证学位证成绩单办理方法:

1客户提供办理密歇根大学|安娜堡分校密歇根大学|安娜堡分校毕业证假文凭信息:姓名生日专业学位毕业时间等(如信息不确定可以咨询顾问:我们有专业老师帮你查询);

2开始安排制作毕业证成绩单电子图;

3毕业证成绩单电子版做好以后发送给您确认;

4毕业证成绩单电子版您确认信息无误之后安排制作成品;

5成品做好拍照或者视频给您确认;

6快递给客户(国内顺丰国外DHLUPS等快读邮寄)

— — — — 我们是挂科和未毕业同学们的福音我们是实体公司精益求精的工艺! — — — -

一真实留信认证的作用(私企外企荣誉的见证):

1:该专业认证可证明留学生真实留学身份同时对留学生所学专业等级给予评定。

2:国家专业人才认证中心颁发入库证书这个入网证书并且可以归档到地方。

3:凡是获得留信网入网的信息将会逐步更新到个人身份内将在公安部网内查询个人身份证信息后同步读取人才网入库信息。

4:个人职称评审加20分个人信誉贷款加10分。

5:在国家人才网主办的全国网络招聘大会中纳入资料供国家500强等高端企业选择人才。听话天天呆在小屋里除了看书写作业就是睡觉看电视屋里很黑很闷白天也得开灯开风扇山娃不想浪费电总将小方桌搁在门口看书写作业有一次山娃坐在门口写作业写着写着竟伏在桌上睡着了迷迷糊糊中山娃似乎听到了父亲的脚步声当他晃晃悠悠站起来时才诧然发现一位衣衫破旧的妇女挎着一只硕大的蛇皮袋手里拎着长铁钩正站在门口朝黑色的屋内张望不好坏人小偷山娃一怔却也灵机一动立马仰起头双手拢在嘴边朝楼上大喊:“爸爸爸——有人找——喜

按照学校原版(Greenwich文凭证书)格林威治大学毕业证快速办理

出售买大学文凭【微信:176555708】【(Greenwich毕业证书)格林威治大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

一比一原版(Adelaide文凭证书)阿德莱德大学毕业证如何办理

毕业原版【微信:176555708】【(Adelaide毕业证书)阿德莱德大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

一比一原版(IIT毕业证)伊利诺伊理工大学毕业证如何办理

IIT本科学位证成绩单【微信95270640】(伊利诺伊理工大学毕业证成绩单本科学历)Q微信95270640(补办IIT学位文凭证书)伊利诺伊理工大学留信网学历认证怎么办理伊利诺伊理工大学毕业证成绩单精仿本科学位证书硕士文凭证书认证Seneca College diplomaoffer,Transcript办理硕士学位证书造假伊利诺伊理工大学假文凭学位证书制作IIT本科毕业证书硕士学位证书精仿伊利诺伊理工大学学历认证成绩单修改制作,办理真实认证、留信认证、使馆公证、购买成绩单,购买假文凭,购买假学位证,制造假国外大学文凭、毕业公证、毕业证明书、录取通知书、Offer、在读证明、雅思托福成绩单、假文凭、假毕业证、请假条、国际驾照、网上存档可查!

办国外伊利诺伊理工大学伊利诺伊理工大学毕业证offer教育部学历学位认证留信认证大使馆认证留学回国人员证明修改成绩单信封申请学校offer录取通知书在读证明offer letter。

快速办理高仿国外毕业证成绩单:

1伊利诺伊理工大学毕业证+成绩单+留学回国人员证明+教育部学历认证(全套留学回国必备证明材料给父母及亲朋好友一份完美交代);

2雅思成绩单托福成绩单OFFER在读证明等留学相关材料(申请学校转学甚至是申请工签都可以用到)。

3.毕业证 #成绩单等全套材料从防伪到印刷从水印到钢印烫金高精仿度跟学校原版100%相同。

专业服务请勿犹豫联系我!联系人微信号:95270640诚招代理:本公司诚聘当地代理人员如果你有业余时间有兴趣就请联系我们。

国外伊利诺伊理工大学伊利诺伊理工大学毕业证offer办理过程:

1客户提供办理信息:姓名生日专业学位毕业时间等(如信息不确定可以咨询顾问:我们有专业老师帮你查询);

2开始安排制作毕业证成绩单电子图;

3毕业证成绩单电子版做好以后发送给您确认;

4毕业证成绩单电子版您确认信息无误之后安排制作成品;

5成品做好拍照或者视频给您确认;

6快递给客户(国内顺丰国外DHLUPS等快读邮寄)。哪里父母对我们的爱和思念为我们的生命增加了光彩给予我们自由追求的力量生活的力量我们也不忘感恩正因为这股感恩的线牵着我们使我们在一年的结束时刻义无反顾的踏上了回家的旅途人们常说父母恩最难回报愿我能以当年爸爸妈妈对待小时候的我们那样耐心温柔地对待我将渐渐老去的父母体谅他们以反哺之心奉敬父母以感恩之心孝顺父母哪怕只为父母换洗衣服为父母喂饭送汤按摩酸痛的腰背握着父母的手扶着他们一步一步地慢慢散步.让我们间

一比一原版(UOL文凭证书)利物浦大学毕业证如何办理

毕业原版【微信:176555708】【(UOL毕业证书)利物浦大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

按照学校原版(KCL文凭证书)伦敦国王学院毕业证快速办理

咨询办理ps毕业证【微信:176555708】【(KCL毕业证书)伦敦国王学院毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

Building a Raspberry Pi Robot with Dot NET 8, Blazor and SignalR - Slides Onl...

In this session delivered at Leeds IoT, I talk about how you can control a 3D printed Robot Arm with a Raspberry Pi, .NET 8, Blazor and SignalR.

I also show how you can use a Unity app on an Meta Quest 3 to control the arm VR too.

You can find the GitHub repo and workshop instructions here;

https://bit.ly/dotnetrobotgithub

按照学校原版(UOL文凭证书)利物浦大学毕业证快速办理

一比一办理办理毕业证【微信:176555708】【(UOL毕业证书)利物浦大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

一比一原版(UQ文凭证书)昆士兰大学毕业证如何办理

毕业原版【微信:176555708】【(UQ毕业证书)昆士兰大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

按照学校原版(QU文凭证书)皇后大学毕业证快速办理

补办学校邮寄信封【微信:176555708】【(QU毕业证书)皇后大学毕业证】【微信:176555708】成绩单、外壳、offer、留信学历认证(永久存档真实可查)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【我们承诺采用的是学校原版纸张(纸质、底色、纹路),我们拥有全套进口原装设备,特殊工艺都是采用不同机器制作,仿真度基本可以达到100%,所有工艺效果都可提前给客户展示,不满意可以根据客户要求进行调整,直到满意为止!】

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信176555708】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信176555708】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

留信网服务项目:

1、留学生专业人才库服务(留信分析)

2、国(境)学习人员提供就业推荐信服务

3、留学人员区块链存储服务

→ 【关于价格问题(保证一手价格)】

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:客户在留信官方认证查询网站查询到认证通过结果后付款,不成功不收费!

1比1复刻澳洲皇家墨尔本理工大学毕业证本科学位原版一模一样

原版一模一样【微信:741003700 】【澳洲皇家墨尔本理工大学毕业证本科学位】【微信:741003700 】学位证,留信认证(真实可查,永久存档)offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原海外各大学 Bachelor Diploma degree, Master Degree Diploma

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微741003700

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

Recently uploaded (20)

Building a Raspberry Pi Robot with Dot NET 8, Blazor and SignalR - Slides Onl...

Building a Raspberry Pi Robot with Dot NET 8, Blazor and SignalR - Slides Onl...

Production.pptxd dddddddddddddddddddddddddddddddddd

Production.pptxd dddddddddddddddddddddddddddddddddd

Kermetico HVAF internal diameter spraying tungsten carbide hastelloy coatings

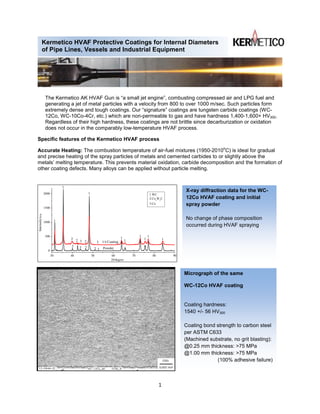

- 1. 1 The Kermetico AK HVAF Gun is “a small jet engine”, combusting compressed air and LPG fuel and generating a jet of metal particles with a velocity from 800 to over 1000 m/sec. Such particles form extremely dense and tough coatings. Our “signature” coatings are tungsten carbide coatings (WC- 12Co, WC-10Co-4Cr, etc.) which are non-permeable to gas and have hardness 1,400-1,600+ HV300. Regardless of their high hardness, these coatings are not brittle since decarburization or oxidation does not occur in the comparably low-temperature HVAF process. Specific features of the Kermetico HVAF process Accurate Heating: The combustion temperature of air-fuel mixtures (1950-2010 o C) is ideal for gradual and precise heating of the spray particles of metals and cemented carbides to or slightly above the metals’ melting temperature. This prevents material oxidation, carbide decomposition and the formation of other coating defects. Many alloys can be applied without particle melting. 30 40 50 60 70 80 90 0 500 1000 1500 2000 2 C4 Coating Powder 33 222 1 1 1 1 1 1 1 1 1:WC 2:Co3 W3 C 3:Co 1 2/degree Internsity/a.u. 3 3 2 22 X-ray diffraction data for the WC- 12Co HVAF coating and initial spray powder No change of phase composition occurred during HVAF spraying Micrograph of the same WC-12Co HVAF coating Coating hardness: 1540 +/- 56 HV300 Coating bond strength to carbon steel per ASTM C633 (Machined substrate, no grit blasting): @0.25 mm thickness: >75 MPa @1.00 mm thickness: >75 MPa (100% adhesive failure) Kermetico HVAF Protective Coatings for Internal Diameters of Pipe Lines, Vessels and Industrial Equipment

- 2. 2 Heating efficiency: The spray particles are fed through the combustion chamber. Thus, their heating occurs at high pressure, where heat transfer is the most efficient. The size of the chamber provides a long residence time for the spray particles to heat. Thus the energy transfer efficiency increases noticeably compared to other high-velocity spraying methods, resulting in much higher spray rates with HVAF guns, over 33 kg/hour for large guns and up to 5 kg/hour for the smallest, 30 kW power guns. Acceleration efficiency: The large diameter of the nozzle eliminates the nozzle length limitations, known to other guns. The spray particles can be accelerated up to the gas velocity (well over 1000 m/s). Herewith, the spray particle velocity is often purposely limited to reach needed deposit efficiency (cost) and decrease residual stresses in the coating. Uniform coating quality: The diameter of the spray particle jet is several times smaller than the nozzle diameter. The influence of the nozzle wall on the spray particle velocity is negligible, providing even acceleration of the particles and improved consistency of the coating structure and properties. Kermetico HVAF Guns Kermetico Inc. has been developing and manufacturing HVAF thermal spray equipment since 2006. The company is actively involved in the coating services business, spraying the parts as small as a fraction of an inch and as large as 20,000 lbs.(9 ton) hydro-turbine rotors and 6-feet diameter x 25-ft long (1800 x 7500 mm) oil refinery vessels in its spray shops, located in the Benicia Industrial Park, California. In order to provide the needed flexibility and efficiency of coating applications for different size parts, Kermetico Inc. developed the range of AK-HVAF gun of different power: AK7 200 kW guns for the deposition of coatings to massive parts (rollers, plates) and vessels with internal diameter 6’ (1.8 m) and over AK6 130 kW gun for the deposition of carbide coatings onto shafts and rollers 0.5-8” in diameter, elongated parts (external surfaces of pipes and rotors) and vessels with internal diameter over 4’ (1.2 m) AK5 80 kW gun for the deposition of coatings onto small diameter or thin-wall parts, as well as for spraying interiors of pipes and vessels 8-60” (200-1500 mm) in diameter AK-ID 35 kW gun for spraying internal diameters as small as 3.15” (80mm). Standard reach is from 3’ to 5’ (0.9-1.5 m)

- 3. 3 Rotating AK-HVAF Guns Rotating guns, a recent development of Kermetico Inc., are ideal tools for the application of coatings inside sophisticated shapes, such as elbows, square-to-round shape transition nozzles, as well as for internal spraying of parts, rotation of which is difficult or impossible such as stationary heavy vessels, vessels with long protruding nozzles, heavy blocks of cylinders, pump housings, etc. High-torque motors are used in Kermetico rotators, while the rotator itself is mounted on the robot or linear movement device. Coating Applications for Internal Surfaces of Vessels and Pipes Hastelloy C Corrosion Resistant Coatings for Oil Refinery Vessels The application of a Hastelloy C coating inside an oil refinery sulfur removal vessel. The vessel is 6’ (1,8 m) in diameter, 25’ (7,5 m) long with only one 2-foot (600 mm) manhole available for internal access. The rotating AK5 gun was used for coating deposition. The cart with the rotating gun traversed inside the vessel. A robot was used for traversing cart. An additional moving arm was used to position the gun and its angle to spray the heads of the vessel. The entire inner surface of the vessel was coated in this way. AK-IDR Suitable for internal diameters 4” (100 mm) or larger. The spray gun is mounted on the rotator RPT-A; the arm allows 1 or 2 feet reach (300 or 600 mm)

- 4. 4 Tungsten Carbide WC-10Co-4Cr Erosion Resistant Coatings Inside Cyclones The WC-10Co-4Cr coating was applied in the refinery coke transport line cyclone with our rotating AK-5 gun. The cyclone was 33” (838 mm) in diameter and 5’ (1500 mm) long. The 4’ protruding transition nozzle did not allow for rotation of the cyclone. The rotating shaft supported the gun at the end making liner movement up to 6’ possible. The nozzle, 12” (300 mm) in diameter and its transition to a rectangle 16 x 9” (400x230 mm) were both sprayed with our AK-5-ID gun, mounted on a 3-foot reach rotating device (below).

- 5. 5 Application of WC-10Co-4Cr coating with our rotating AK-5 gun inside the double-elbow of a coke transport line. The elbows’ internal diameter is12 inches, total length 6 feet. View of coated area:

- 6. 6 Coating Inside Small Diameters Extensive development in 2012 resulted in the creation of the AK-ID HVAF gun, capable of deposition of tungsten carbide coatings inside internal diameters as small as 3.15 inches (80 mm). New ideas were successfully implemented in the design of this gun. With only 30 kW equivalent power the gun sprays 5 kg of tungsten carbide per hour, reaching a hardness of 950 HV300 in 3.75-4.0” internal diameters and over 1200 HV300 hardness in 4.5-5.0” internal diameters. The AK-ID is the smallest high velocity spray gun in the world, capable of depositing quality coatings inside 3.15” (80 mm) internal diameter Micrographs of tungsten carbide WC-10Co-4Cr coating sprayed with AK-ID gun in 4.0” (100mm) (a) and 4.5” (125 mm) (b) ID barrels WC-10Co-4Cr, 4-inch ID Hardness 1155 HV300, Porosity <0.1% WC-10Co-4Cr, 4.5-inch ID Hardness 1300 HV300, Porosity <0.1% a b

- 7. 7 Applications of Coatings with AK-ID HVAF: Barrels and Sleeves ID 4.0” ID 4.625” ID 6.0” ID 3.50”

- 8. 8 Applications of WC-10Co-4Cr Coatings with AK-ID HVAF: 6” (150 mm) ID Coke Transport Pipe

- 9. 9 Application of WC-10Co-4Cr Coating with Rotating AK-IDR Gun inside the Elbows, 6” (150 mm) ID: Contact information: Kermetico Inc. 3900 Oregon Street, Suite 2 Benicia, CA 94510 Phone: +1 (707) 745-3862. Fax: +1 (707) 745-3894 Website: Kermetico.com e-mail: jrienecker@kermetico.com