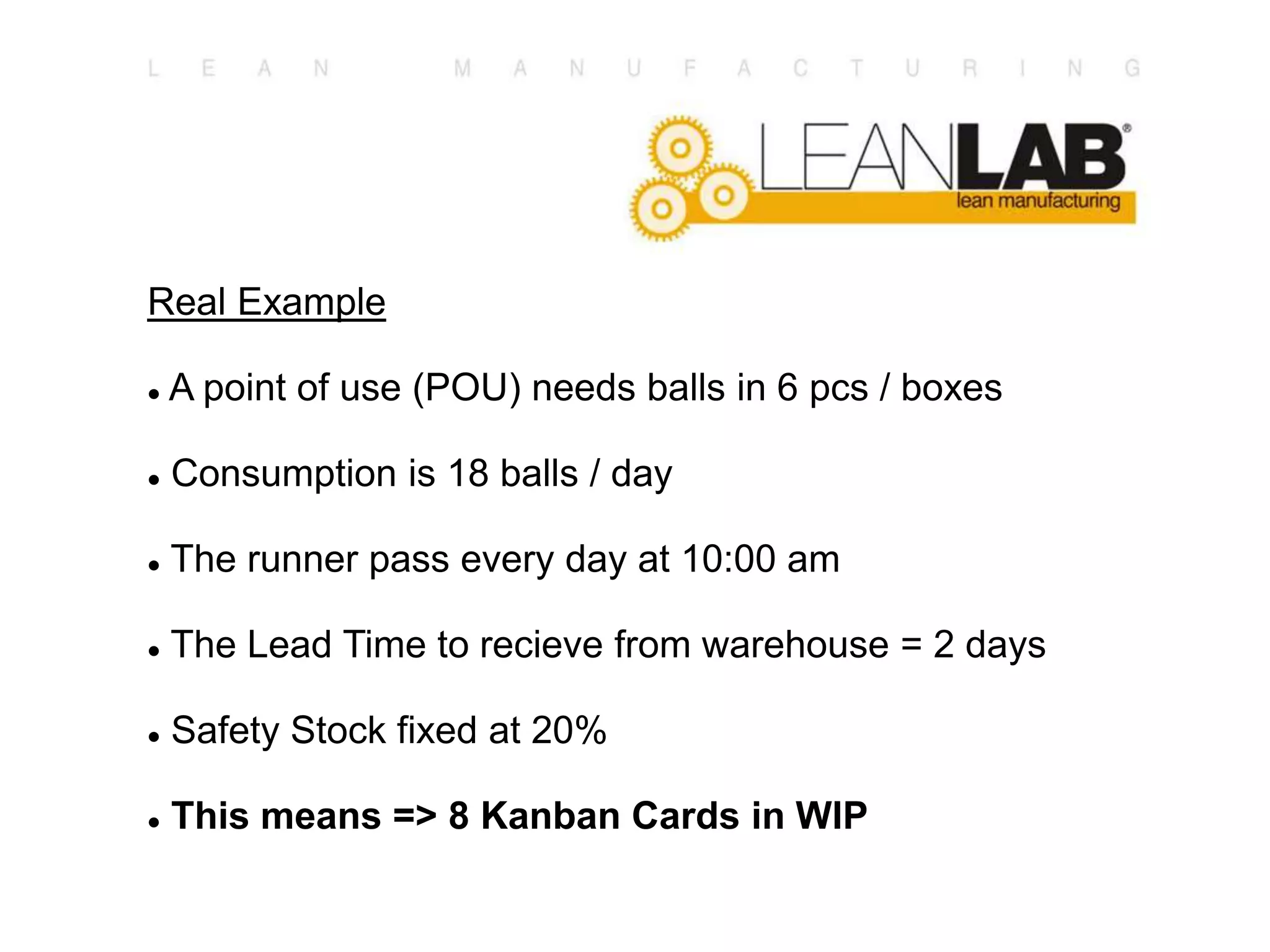

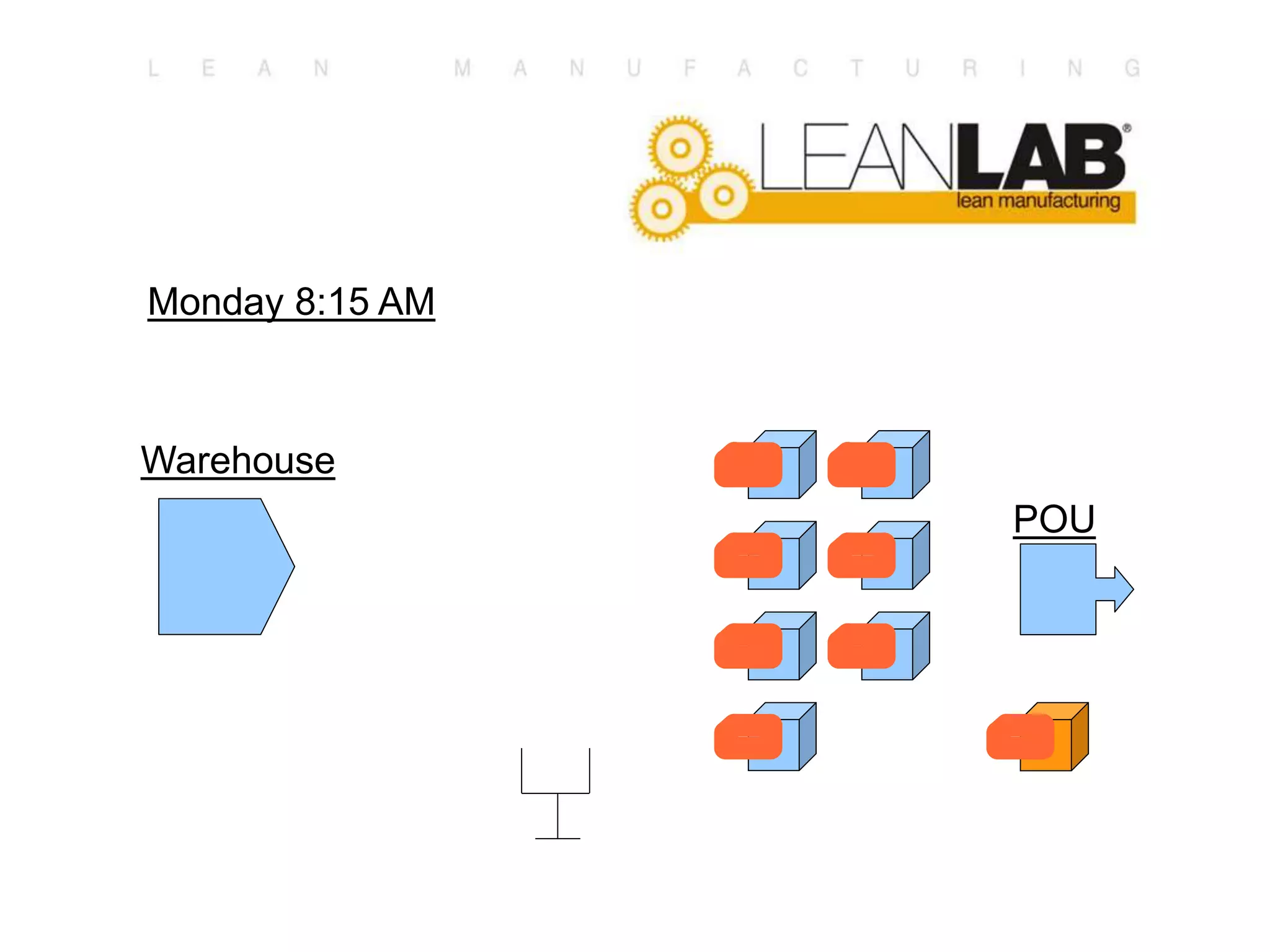

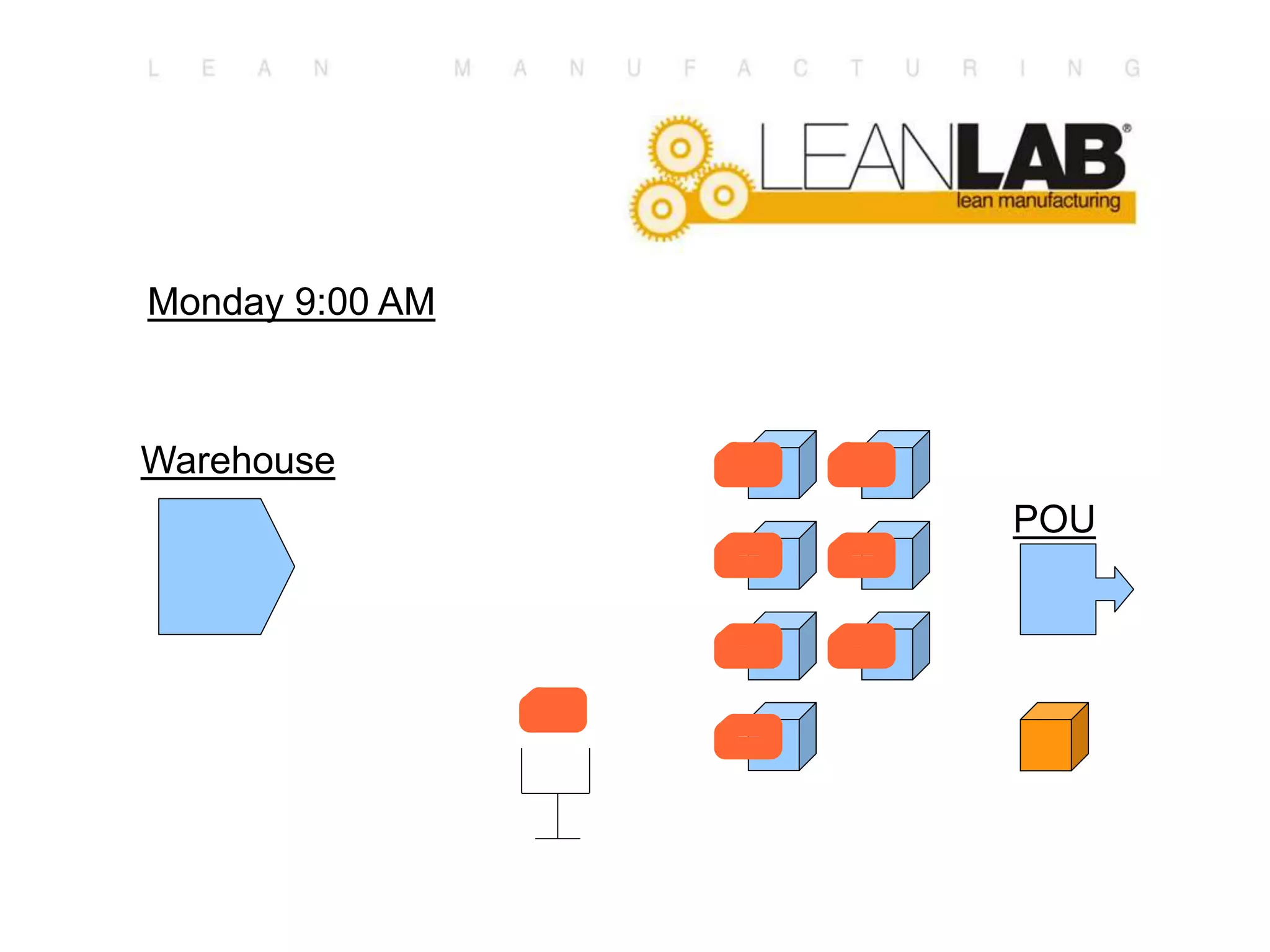

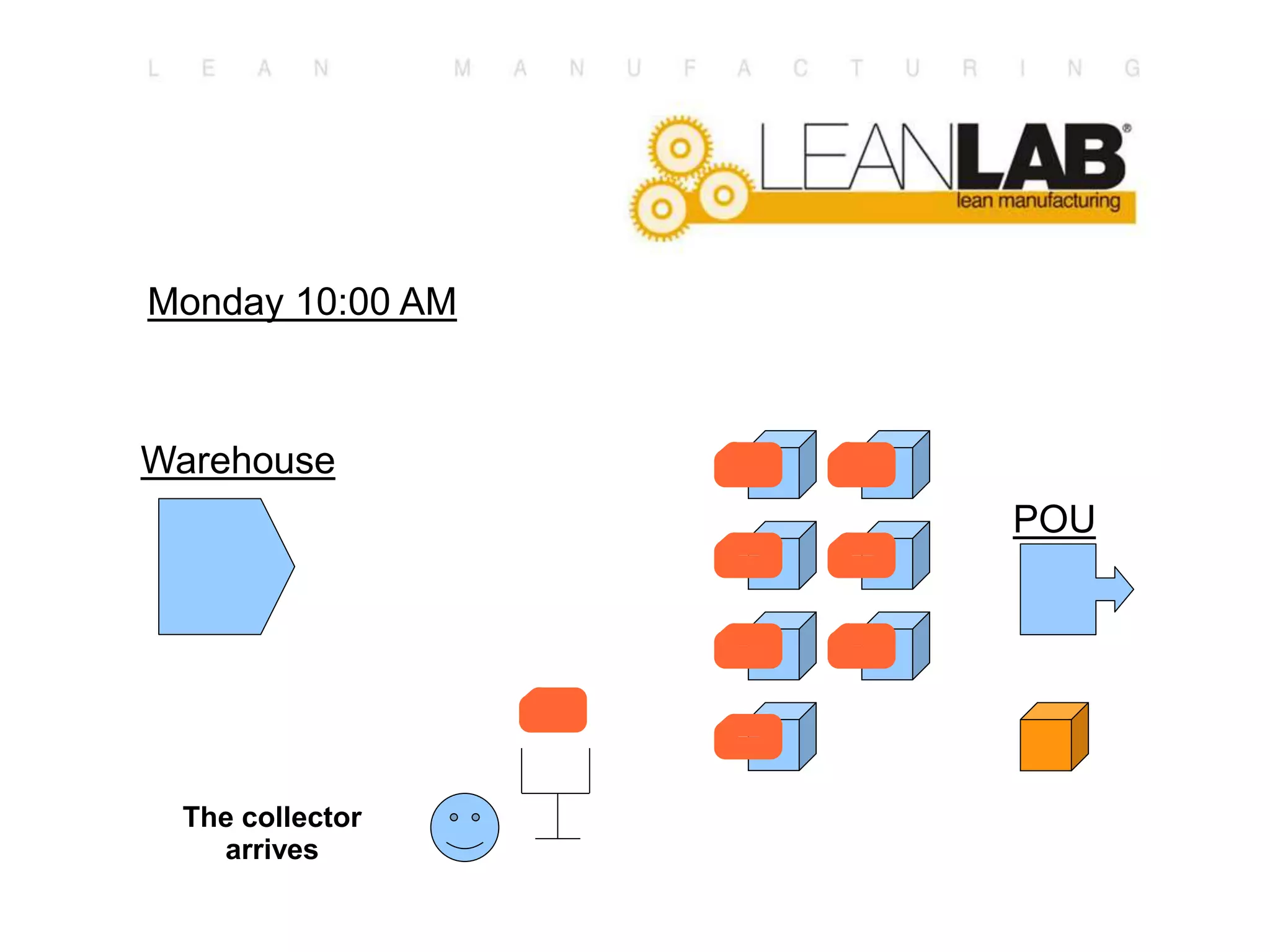

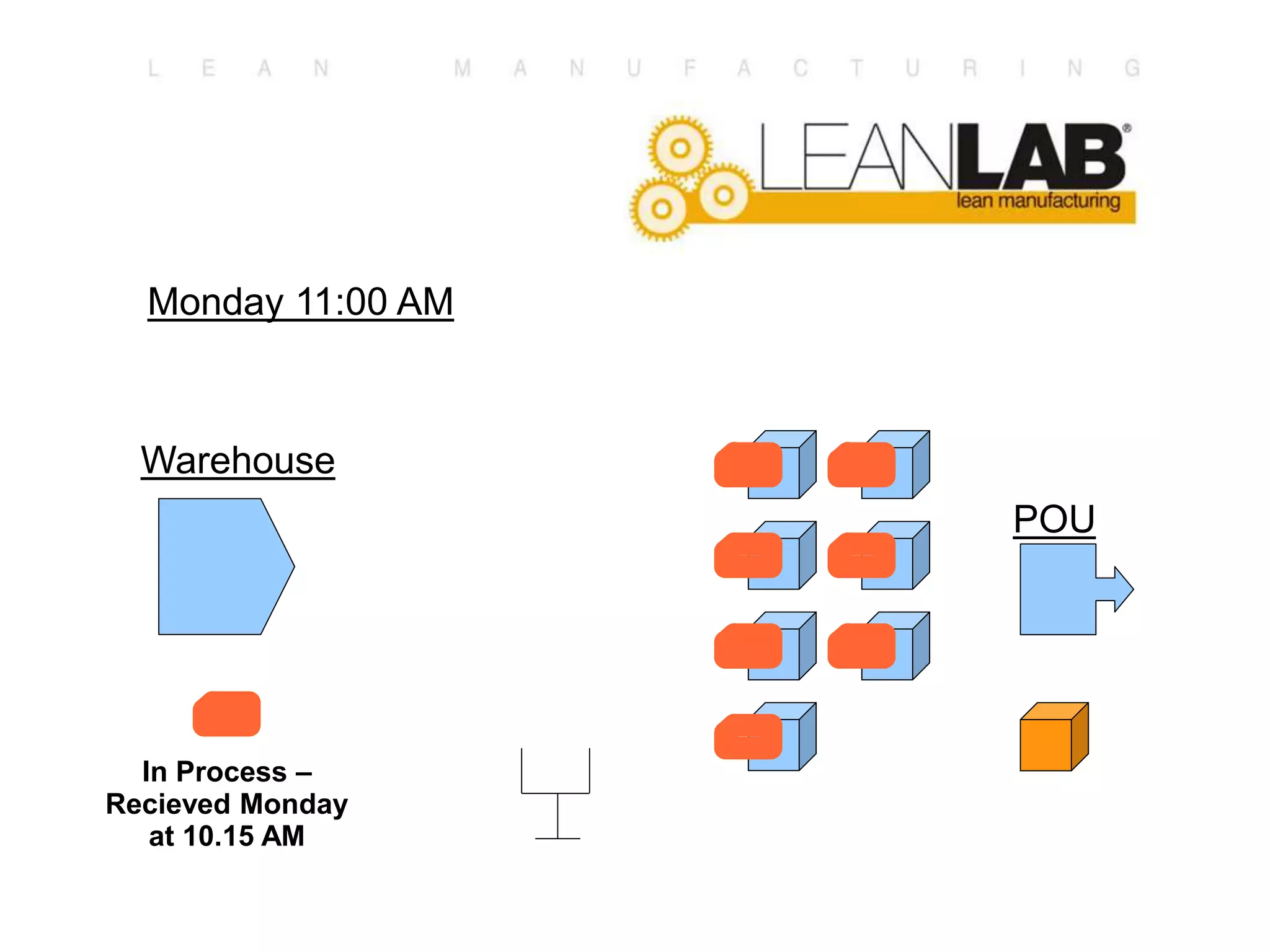

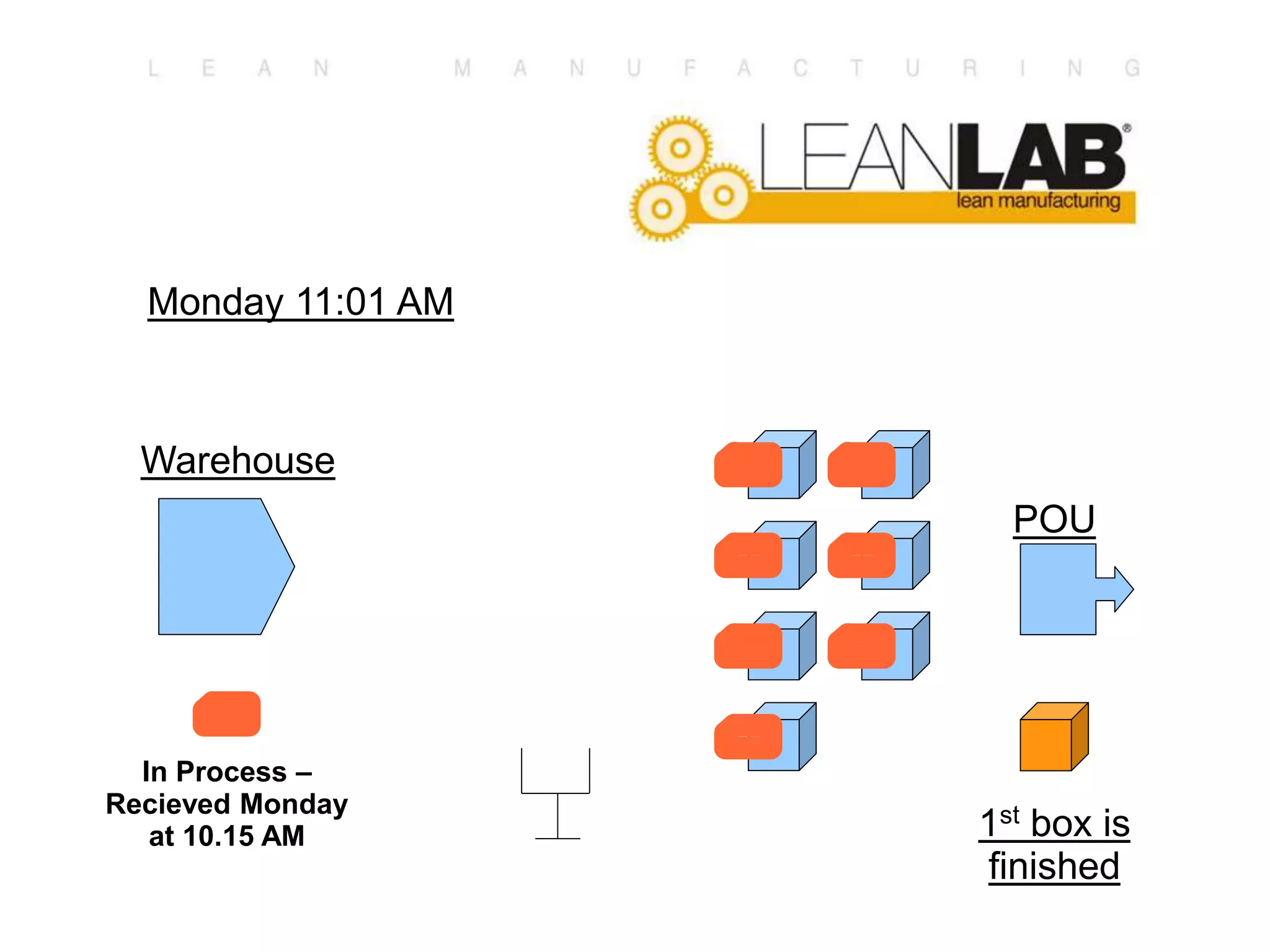

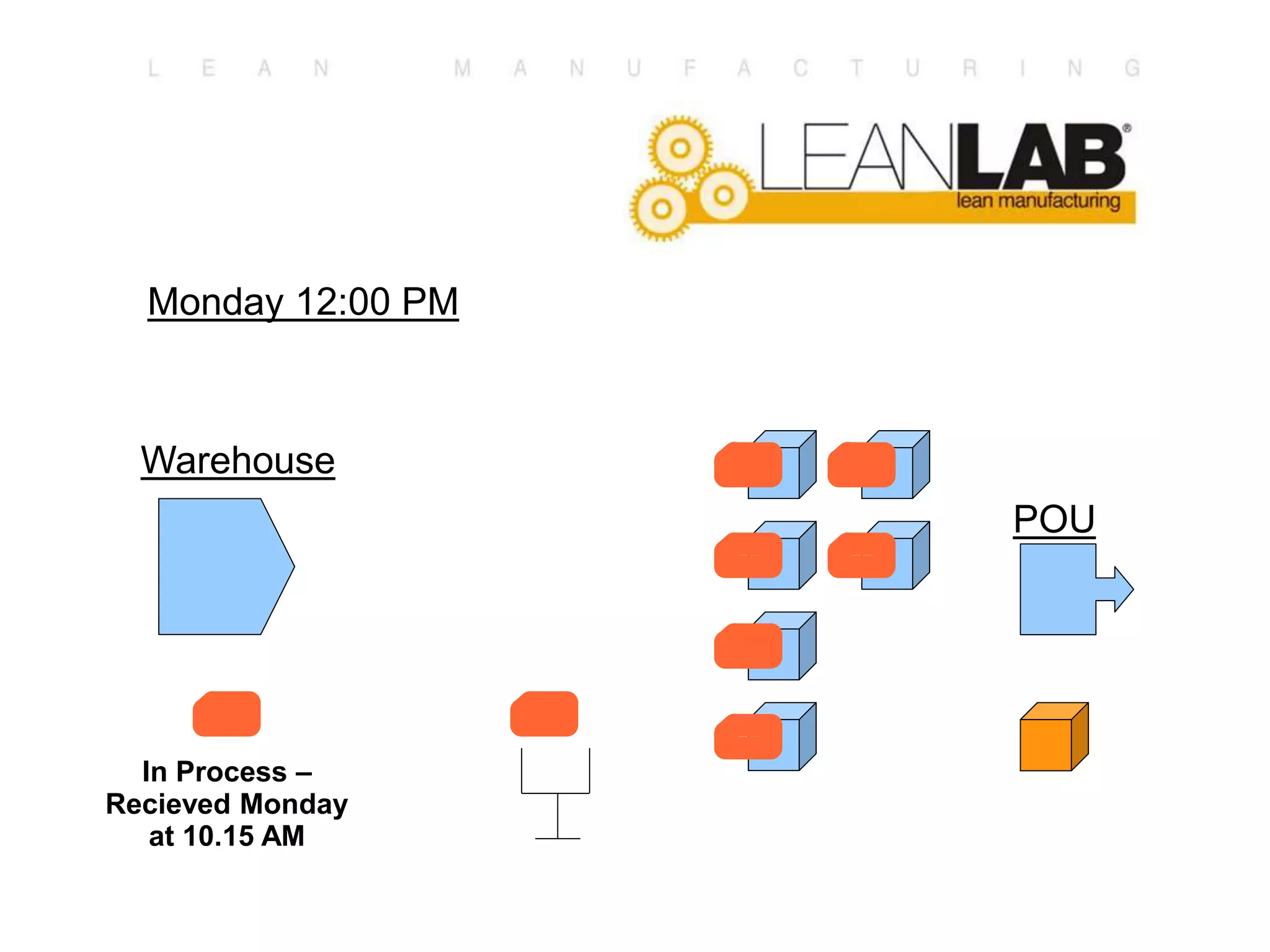

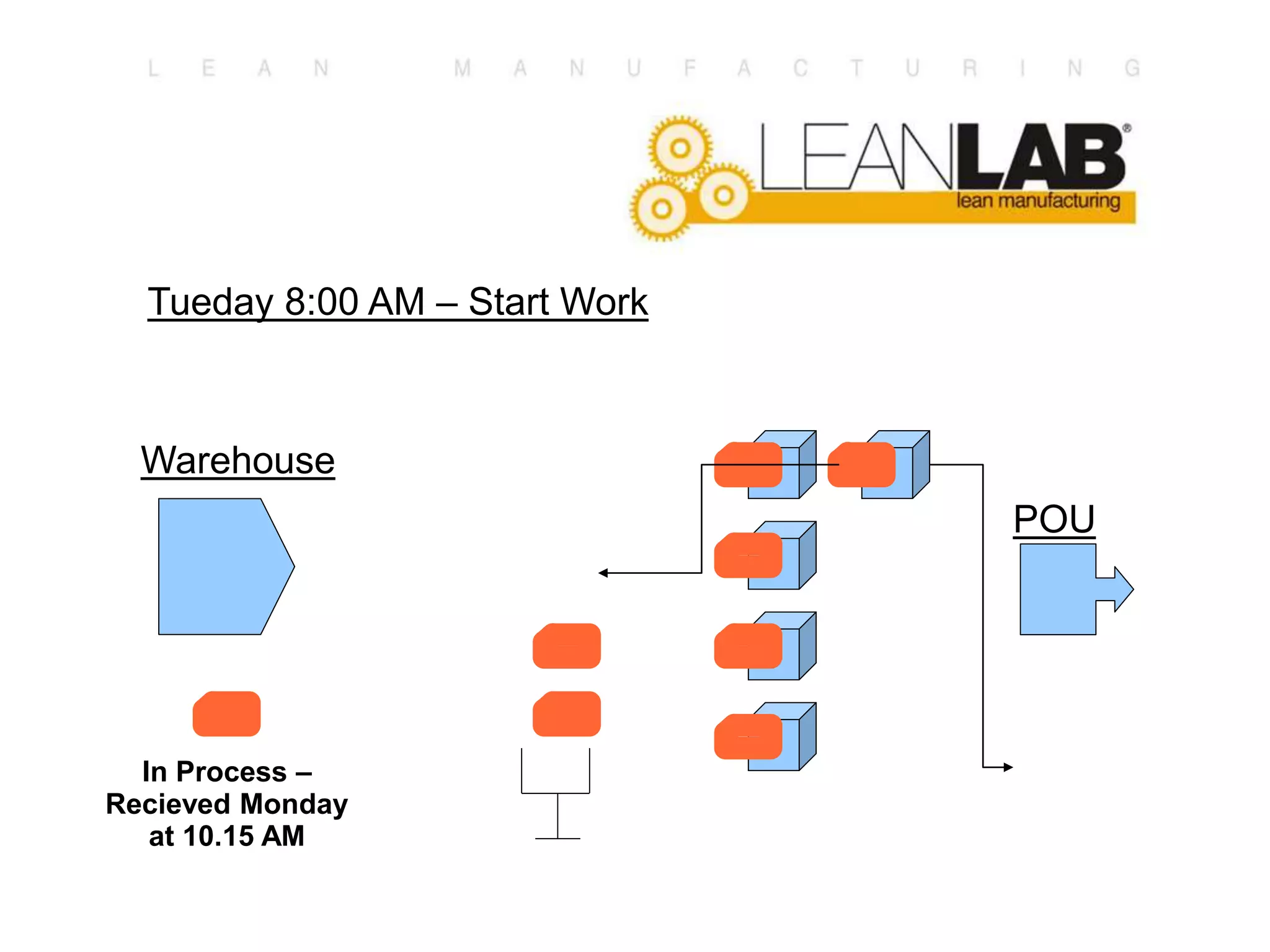

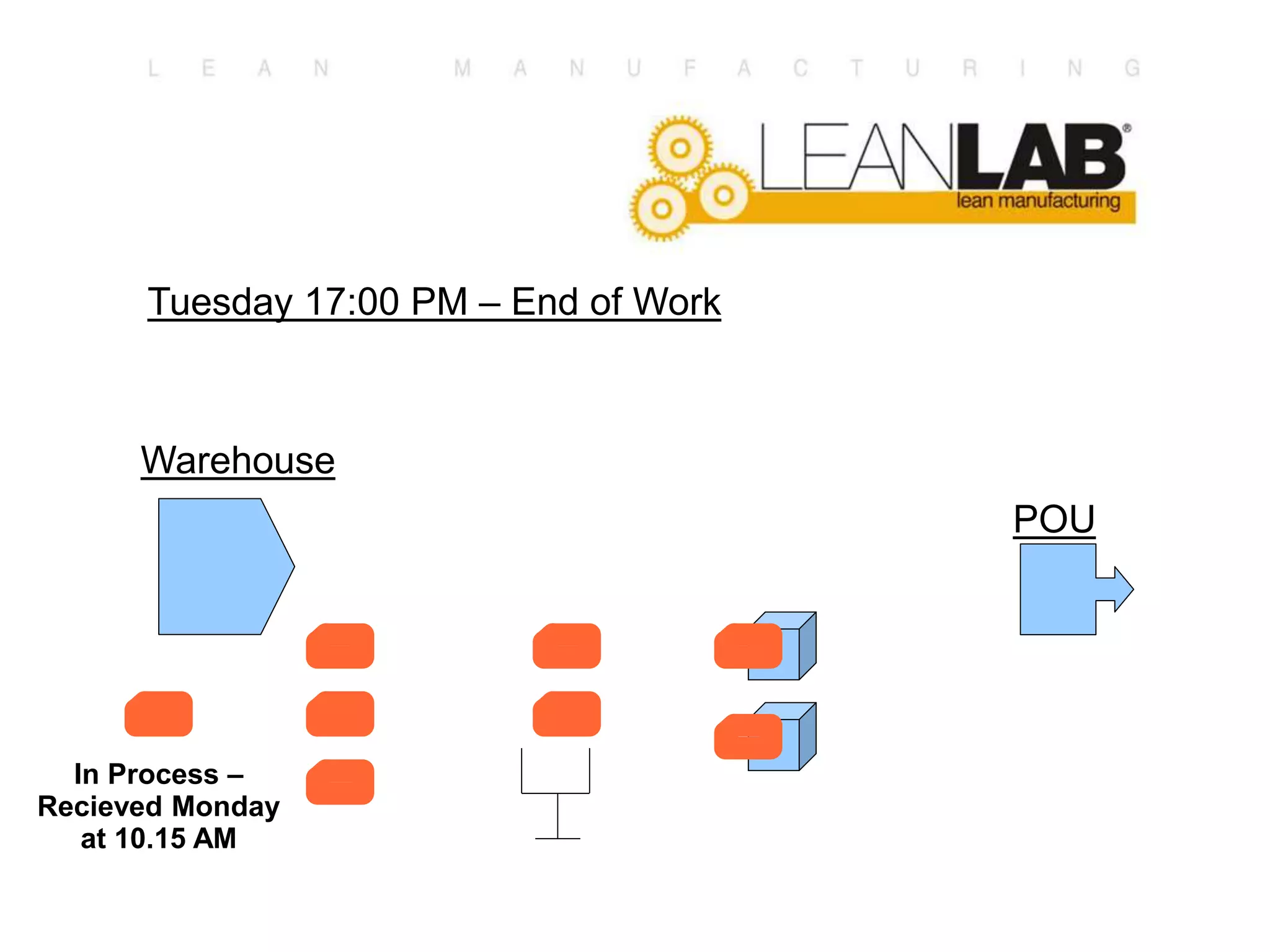

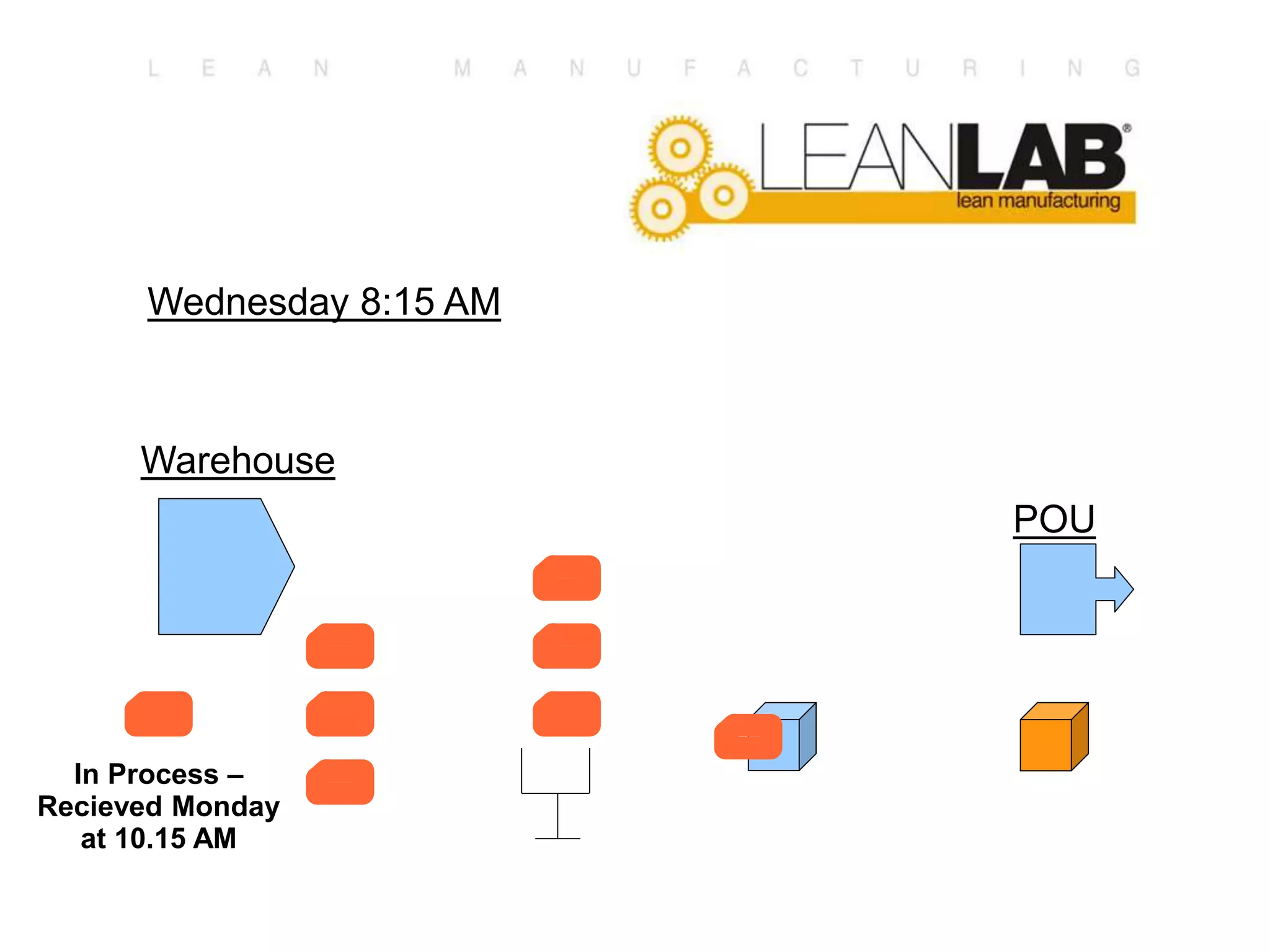

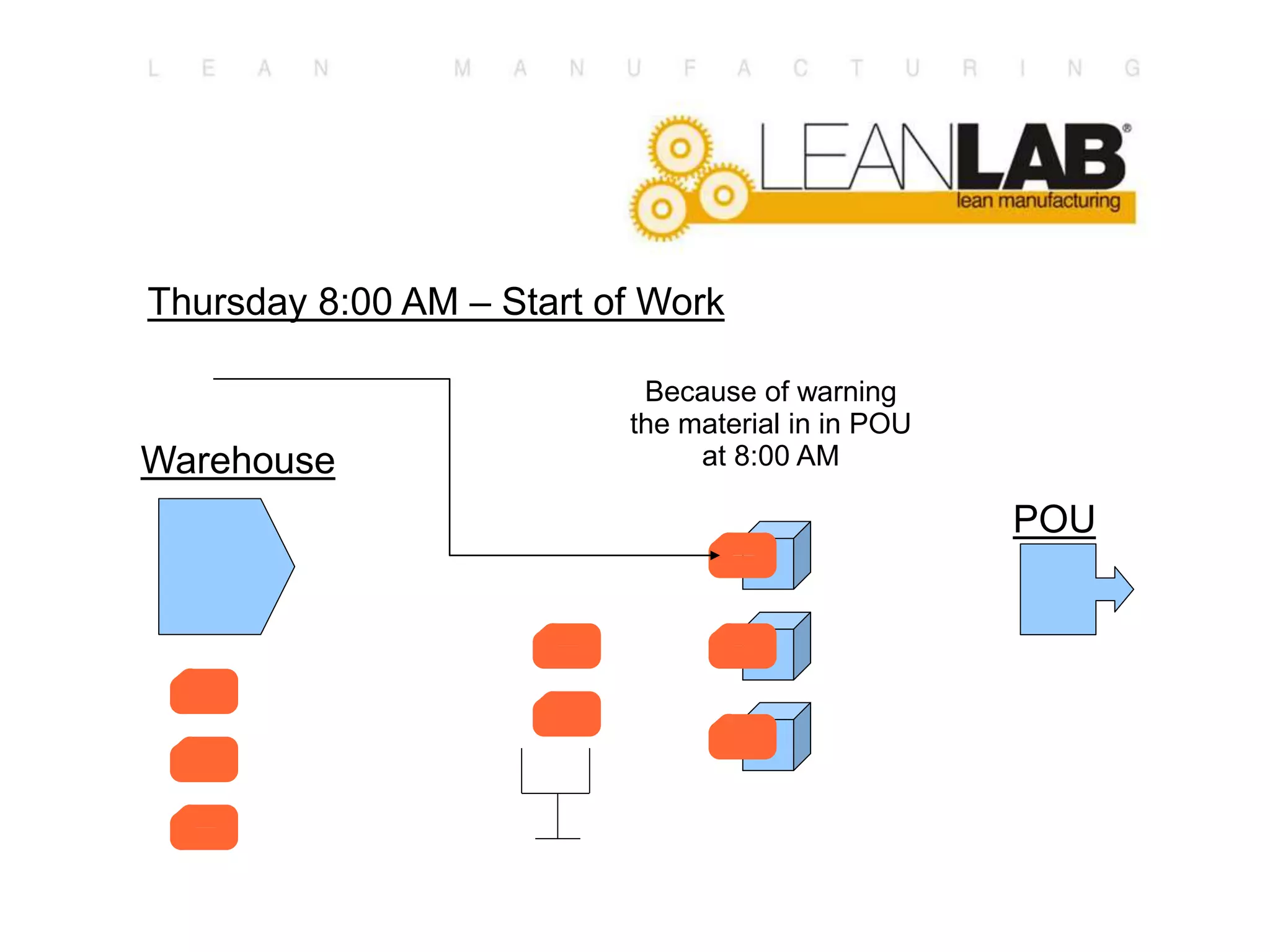

The document describes how a Kanban system works using an example of balls being delivered from a warehouse to a point of use. It shows the workflow over the course of a week with the collector exchanging Kanban cards between the warehouse and point of use each day. Some key considerations are that the work in progress is kept under control, and the actual lead time needs to be calculated more precisely to ensure there are enough Kanban cards to avoid stockouts. The number of cards may need to start higher and then be reduced over time as the system stabilizes.