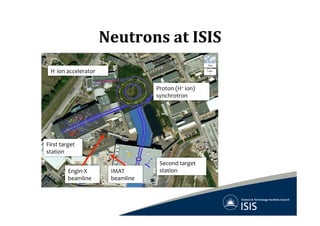

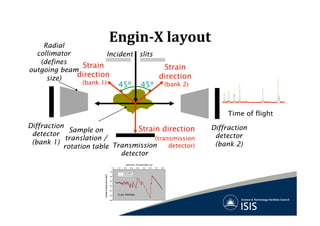

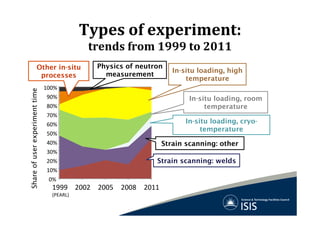

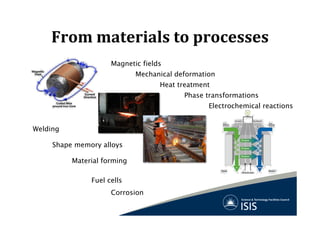

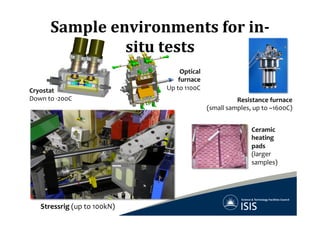

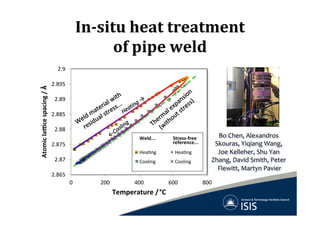

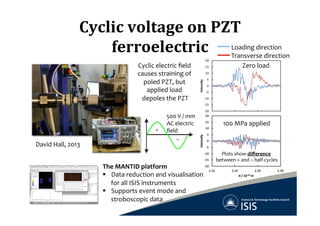

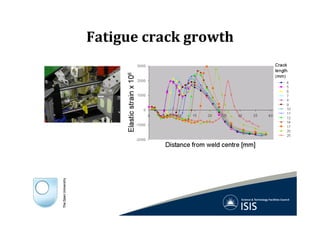

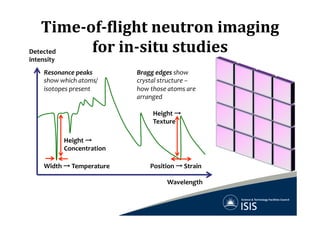

The document discusses using neutrons for in-situ observation of engineering material behavior. It describes the ENGIN-X beamline at ISIS, which allows for various types of in-situ experiments including mechanical deformation, heat treatment, and phase transformations. Examples are given of experiments involving in-situ heat treatment, cyclic electric fields on ferroelectrics, welding, and fatigue crack growth. Practical considerations for in-situ neutron experiments and opportunities for future directions are also outlined.