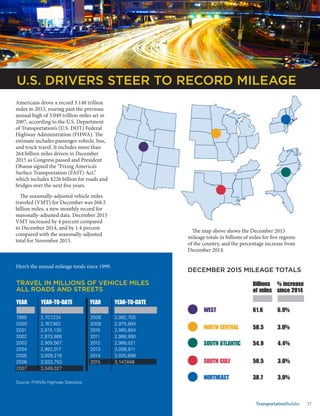

This document is the January-February 2016 issue of Transportation Builder, the official publication of the American Road & Transportation Builders Association (ARTBA). It discusses several key issues and priorities for ARTBA in 2016, including:

1) Ensuring full funding of the surface transportation programs authorized in the FAST Act and obtaining long-term, increased funding for airport capital programs and the prevention of excessive regulatory actions.

2) ARTBA's strategic plan to engage the next generation of industry leaders, including rebranding the Young Executive Development Program as the Industry Leader Development Program and the Young Executive Leadership Council as the Industry Leader Development Council.

3) A new study showing that the Highway Trust Fund faces an annual $18