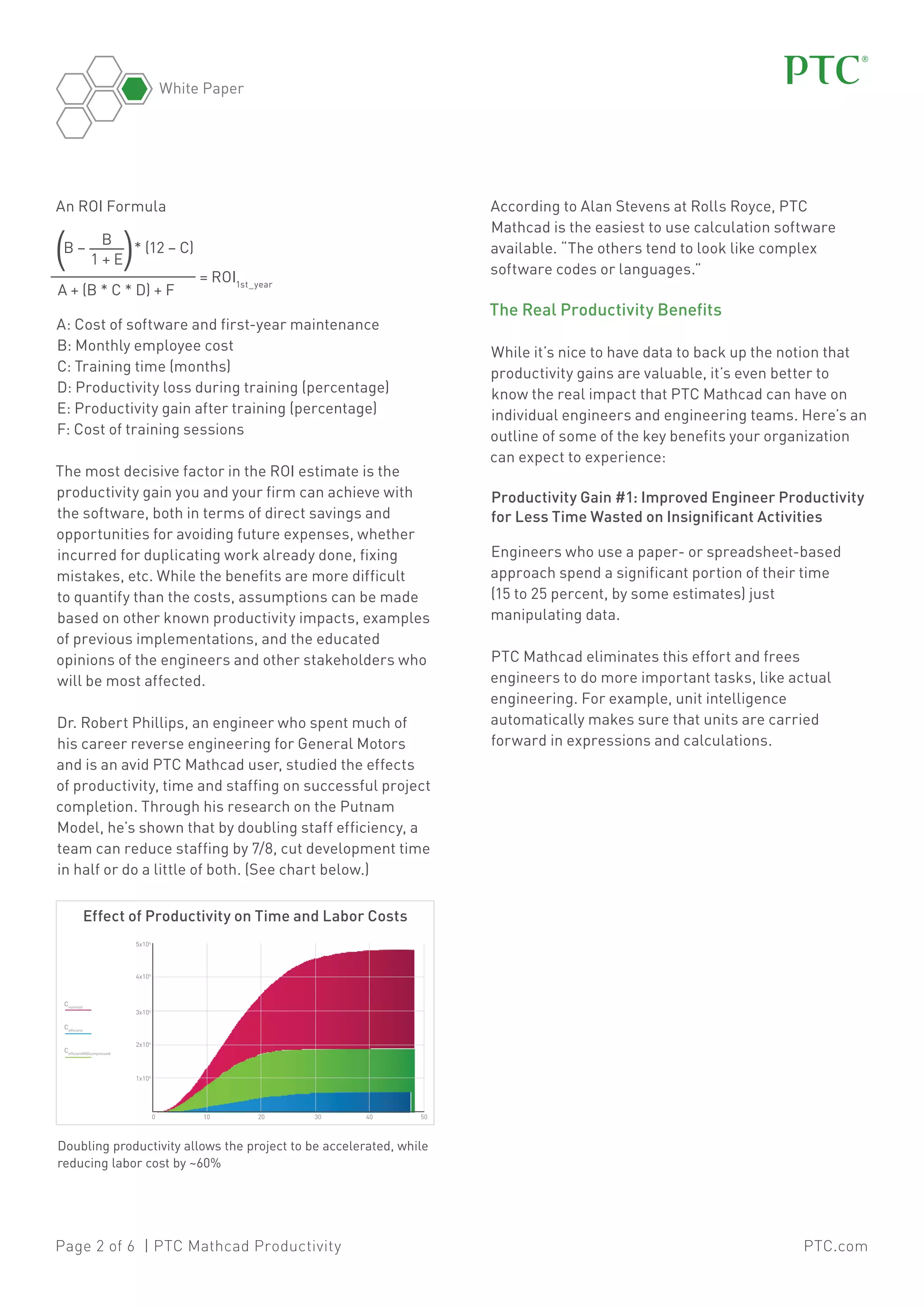

PTC Mathcad software can help engineers improve productivity, accuracy, and transparency. It allows engineers to work faster by automating unit conversions and reducing time spent manipulating data. Errors are less likely as formulas are clearly laid out. PTC Mathcad also enables greater collaboration through transparent documentation of calculations and design intent. Customers report productivity gains of 15-50% and increased computational power for more design exploration.