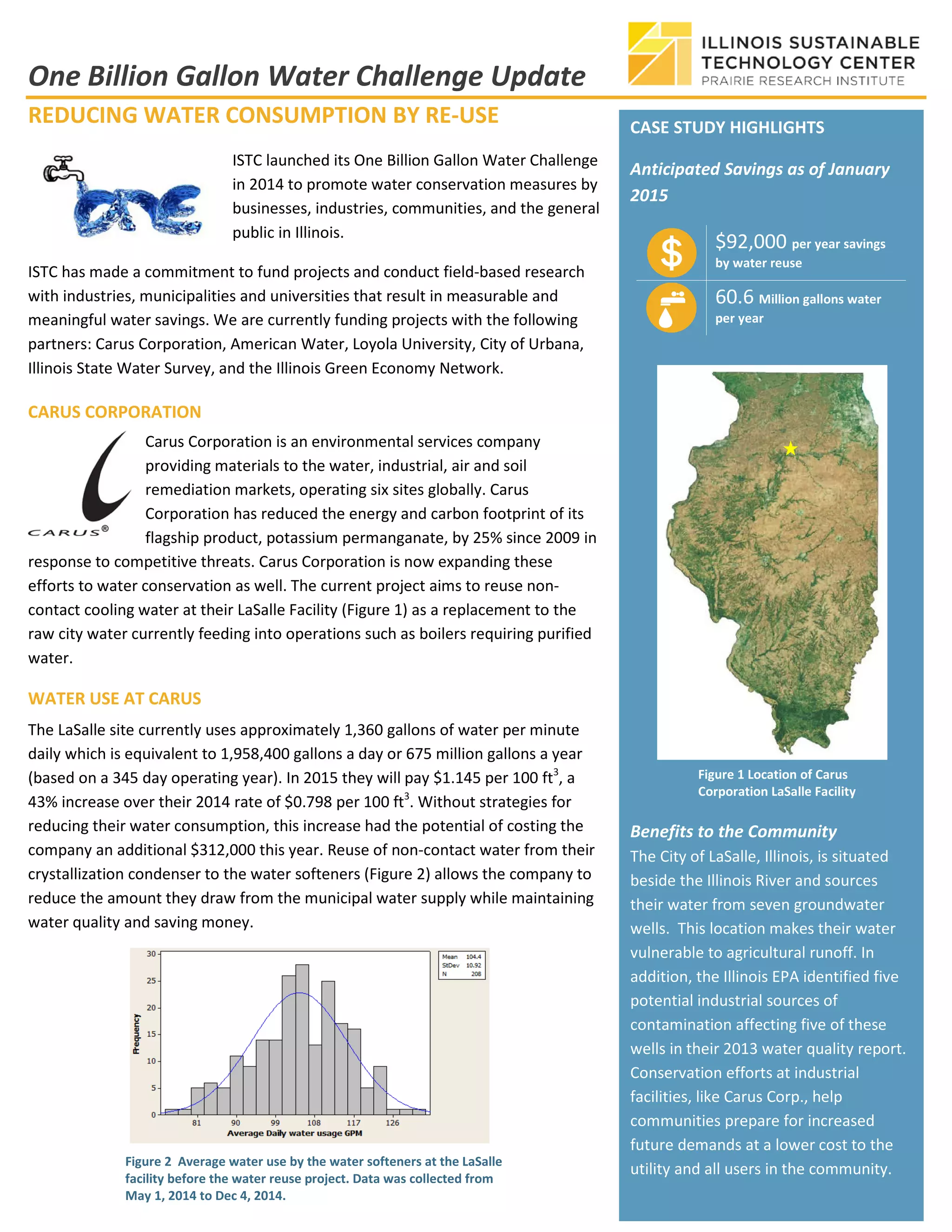

The City of LaSalle, Illinois sources its water from wells vulnerable to contamination. Carus Corporation, located in LaSalle, uses large amounts of water in its industrial processes. To save water and money, Carus implemented a project to reuse non-contact cooling water from its condenser to feed its water softeners, replacing raw city water. Initial results found the project will save over 8.7 million gallons of water annually, reducing Carus' costs and helping the local community manage its water resources more sustainably.