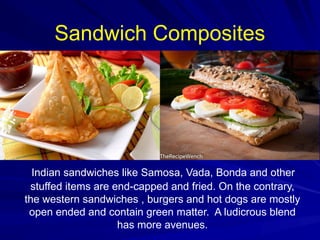

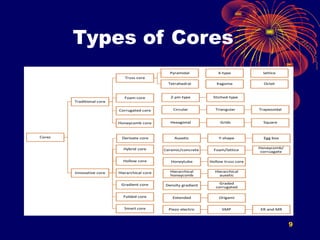

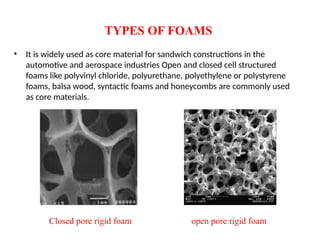

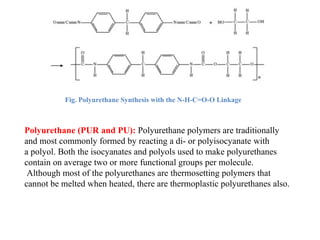

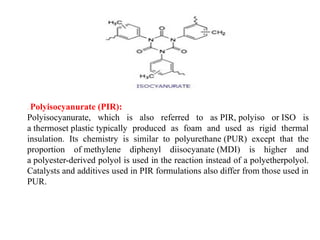

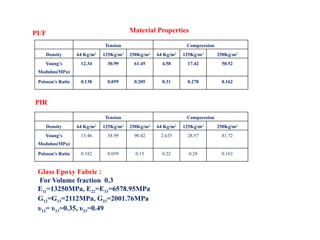

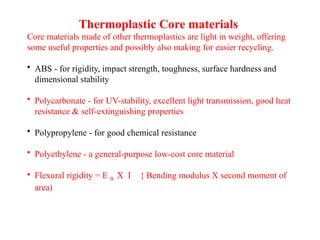

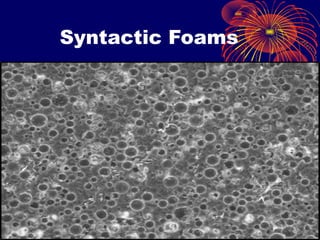

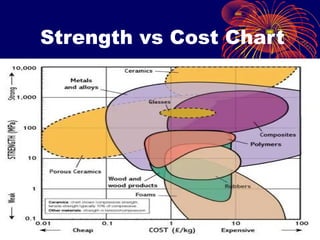

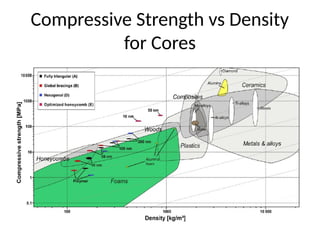

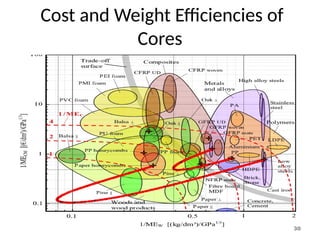

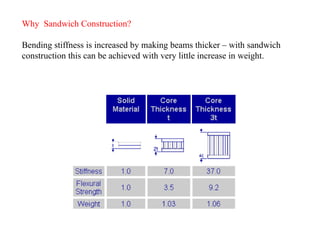

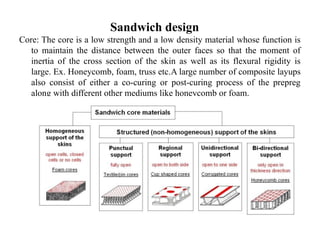

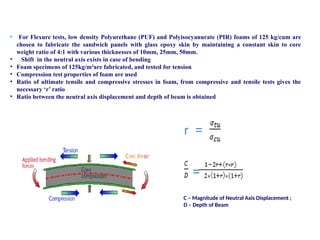

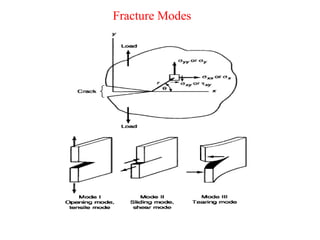

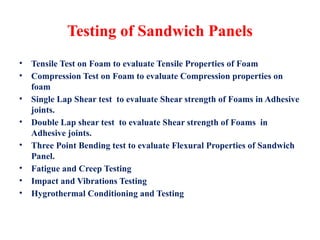

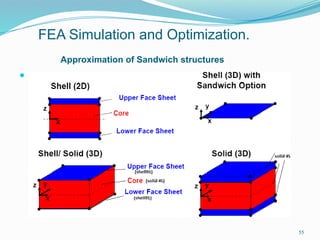

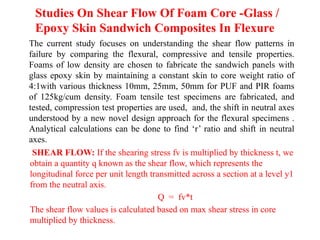

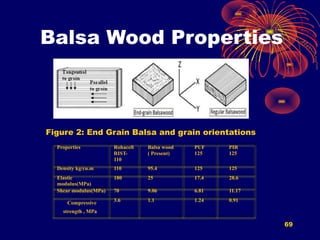

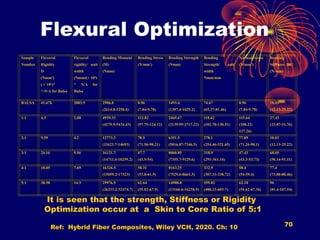

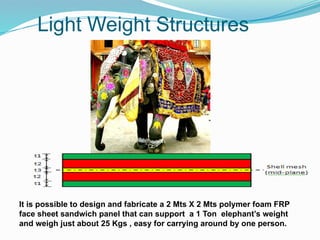

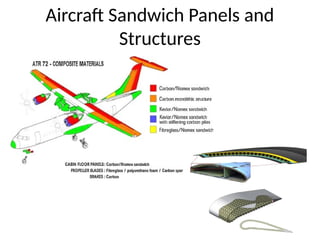

The document discusses advanced functional sandwich composites suitable for structural applications, focusing on their design and multifunctional uses in automotive, aerospace, and marine sectors. It explains the composition of sandwich composites, including various core materials, manufacturing techniques, and optimization methods for enhancing strength and stiffness. Furthermore, it presents experimental approaches for testing properties like tensile strength and flexural rigidity, alongside parameters influencing performance such as foam density and span-to-depth ratios.

![ASTM – Standards.

ASTM D 790M-93 , Standard Test Methods for Flexural Properties of

Unreinforced and Reinforced Plastics and Electrical Insulating Materials

[Metric]

ASTM C273/C273M-11, Shear Properties of Sandwich Core Materials ,

ASTM International, PA, USA.

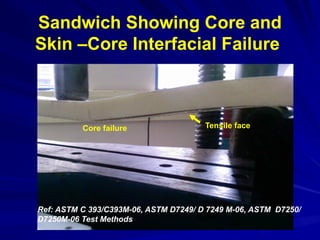

ASTM C393 / C393 M-06, Standard test method for core shear properties

of sandwich constructions by beam flexure.

ASTM D 7249 / D7249 M-06, Standard test method for facing properties

of sandwich constructions by long beam flexure.

ASTM D7250 / D7250 M-06, Standard practice for determining sandwich

beam flexural and shear stiffness.

51](https://image.slidesharecdn.com/introductiontosandwichcomposites-241209174924-422607aa/85/Introduction-to-Sandwich-composites-pptx-51-320.jpg)

![Published papers in journals

• “Flexural optimization of glass fabric-epoxy skin/rigid foam core sandwich composites” in International

Journal of ChemTech Research ,CODEN (USA): IJCRGG ISSN : 0974-4290

Vol.6, No.6, pp 3336-3338, Aug-Sep 2014. Suresh E, Hemnath T, Padmanabhan K

• “The Flexural Properties of Glass Fabric/Epoxy -Rigid Polyurethane Foam Core Sandwich Composites

at Different Span to Depth Ratios and Densities” in International Journal of Structural Analysis & Design –

IJSAD,Volume 1 : Issue 3 [ISSN : 2372-4102],Publication Date : 30 September,2014. Chekuri Surya Teja Varma, M.

Ramya, E. Suresh & K. Padmanabhan

• “Mode-2 double lap shear and peel strength of rigid foam core glass epoxy skin sandwich composites

with different densities” in International Journal of Structural Analysis & Design – IJSAD, Volume 1 : Issue 3 [ISSN

: 2372-4102], Publication Date : 30 September,2014. Chava Uday, M Ramya, E.Suresh & K. Padmanabhan

• “Influence of foam density and span to depth ratio on flexural properties of rigid polyisocyanurate foam

glass fabric epoxy sandwich composites” in International Journal of Structural Analysis & Design –

IJSAD,Volume 1 : Issue 3 [ISSN : 2372-4102],Publication Date : 30 September,2014. Vishakh V, Ramya M, Suresh E,

Padmanabhan K](https://image.slidesharecdn.com/introductiontosandwichcomposites-241209174924-422607aa/85/Introduction-to-Sandwich-composites-pptx-86-320.jpg)