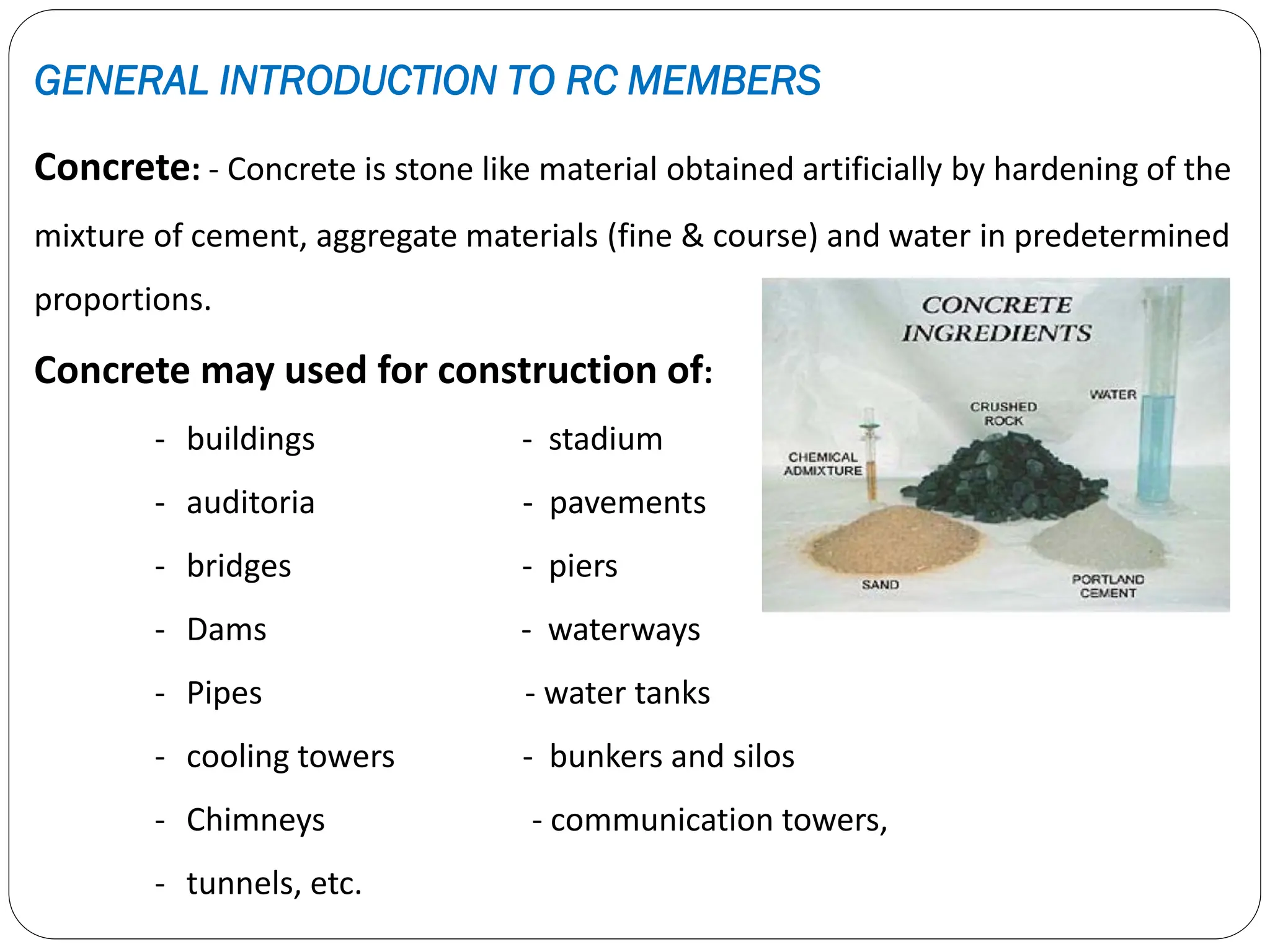

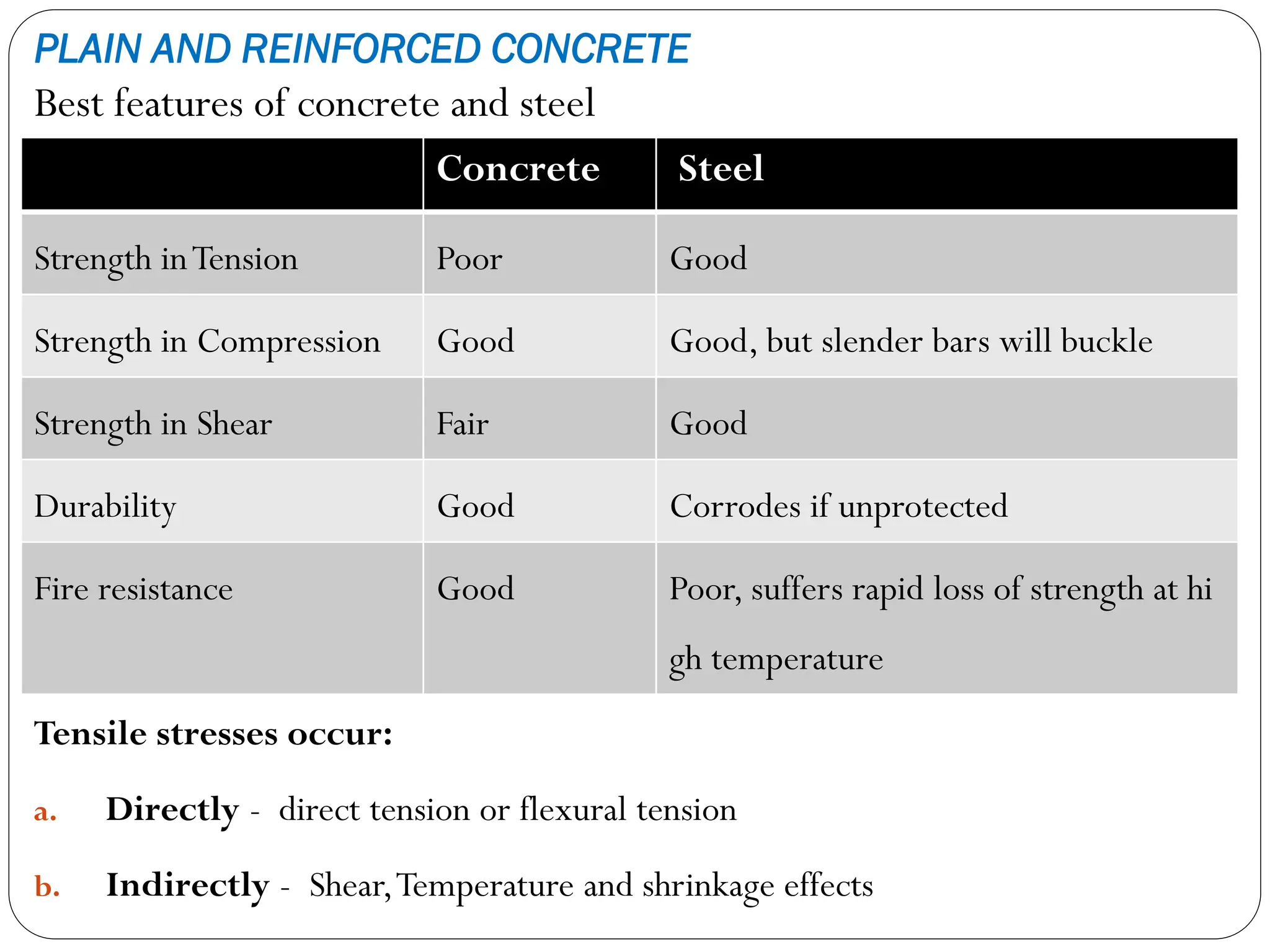

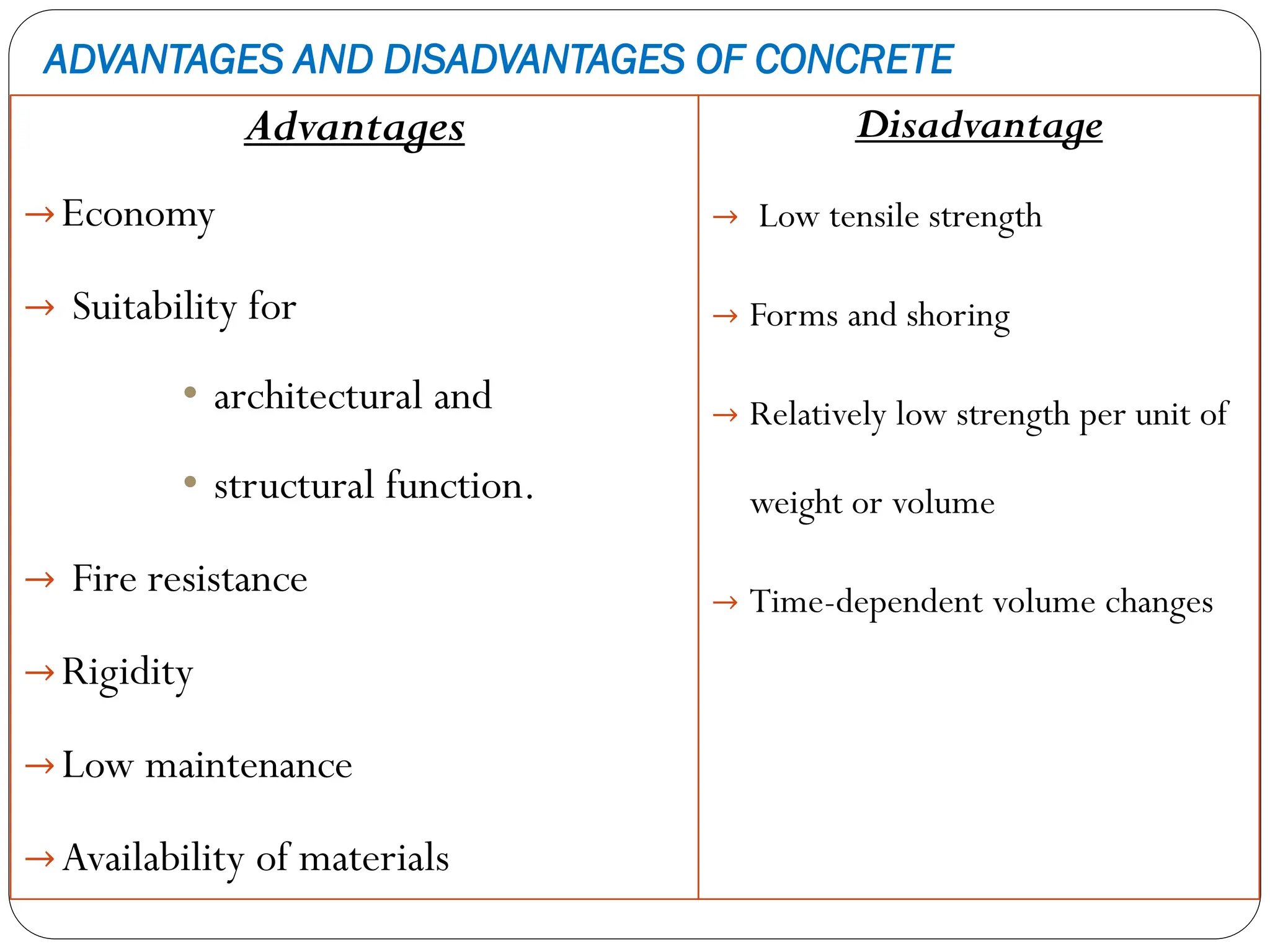

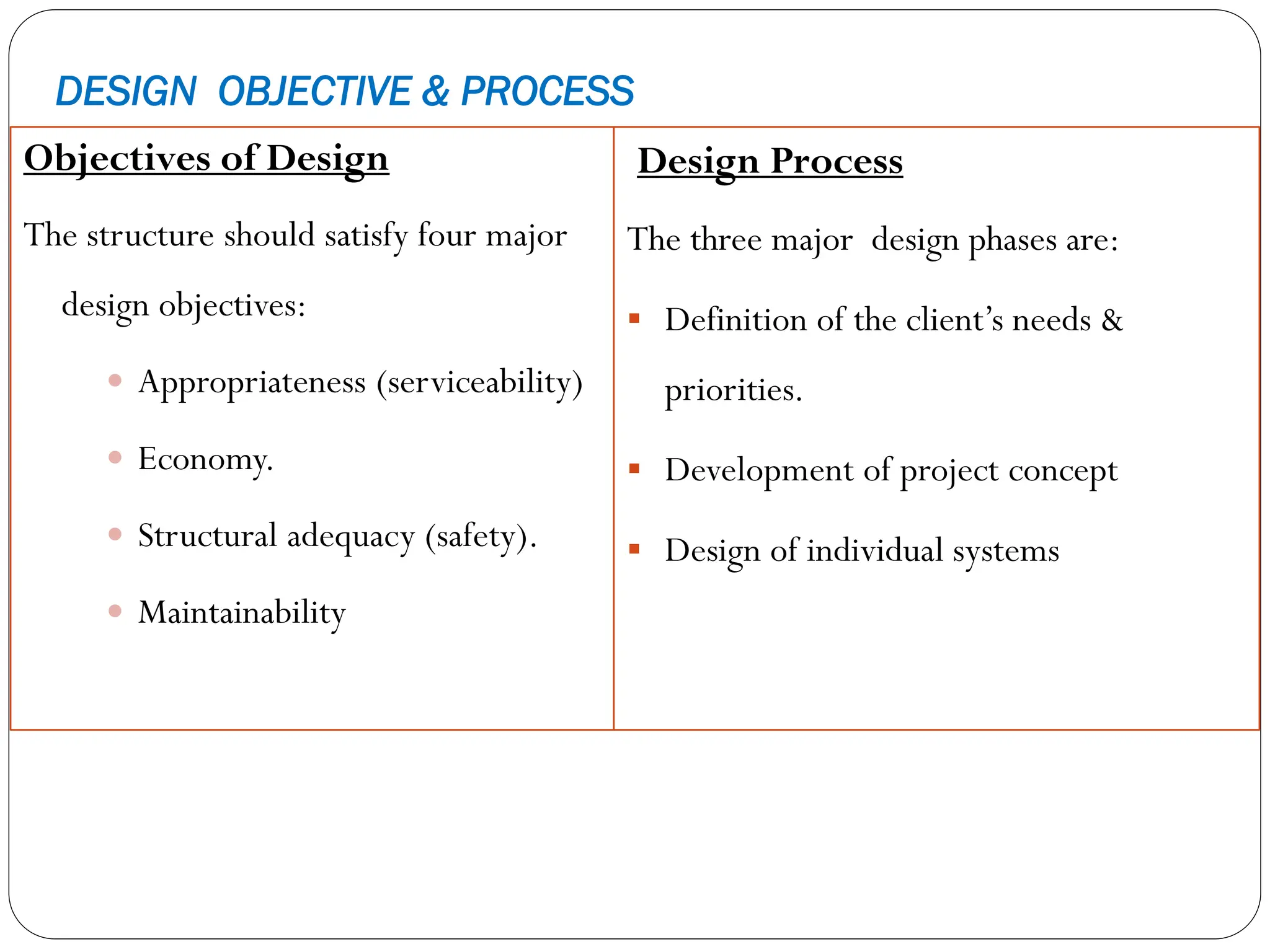

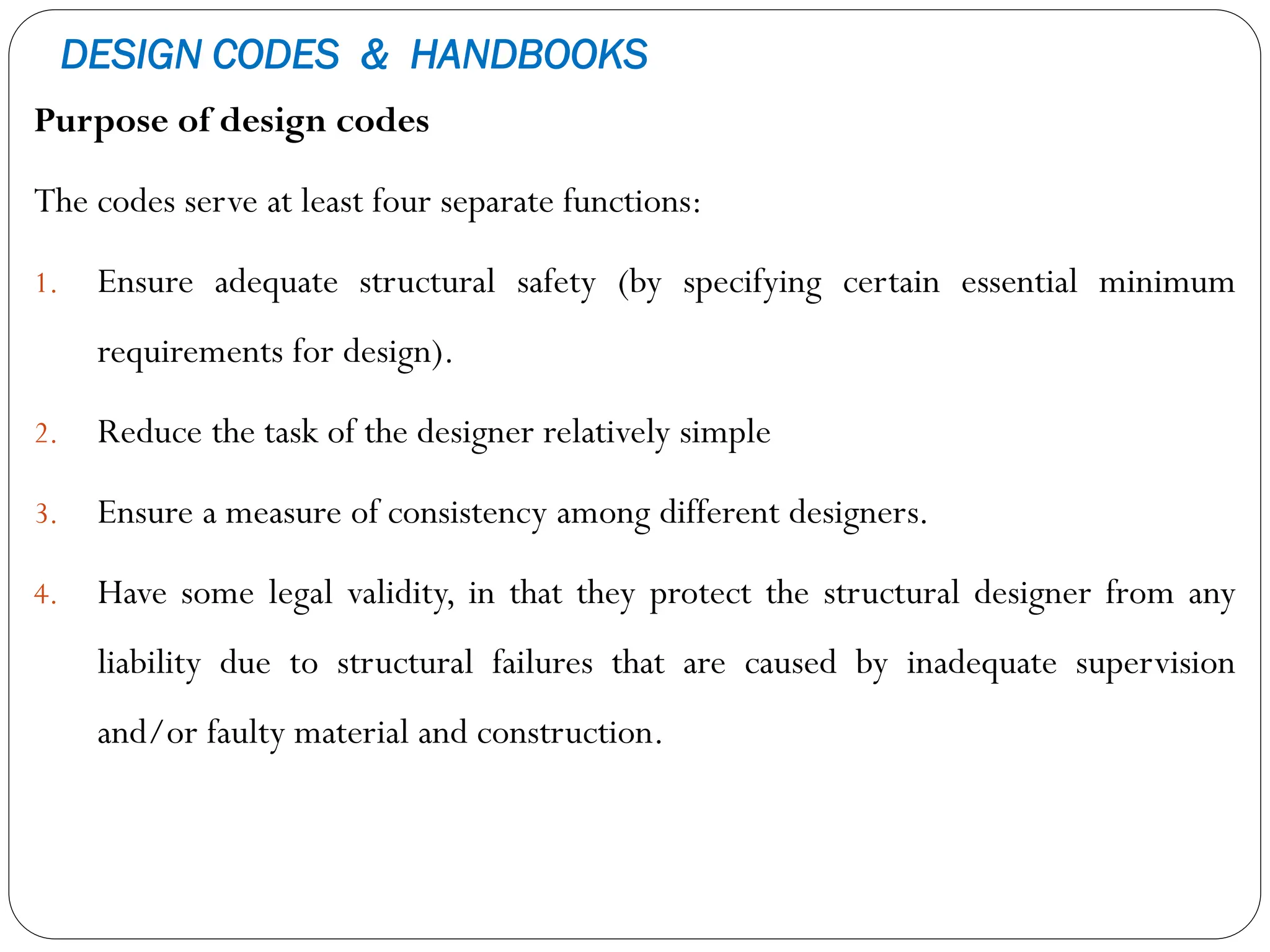

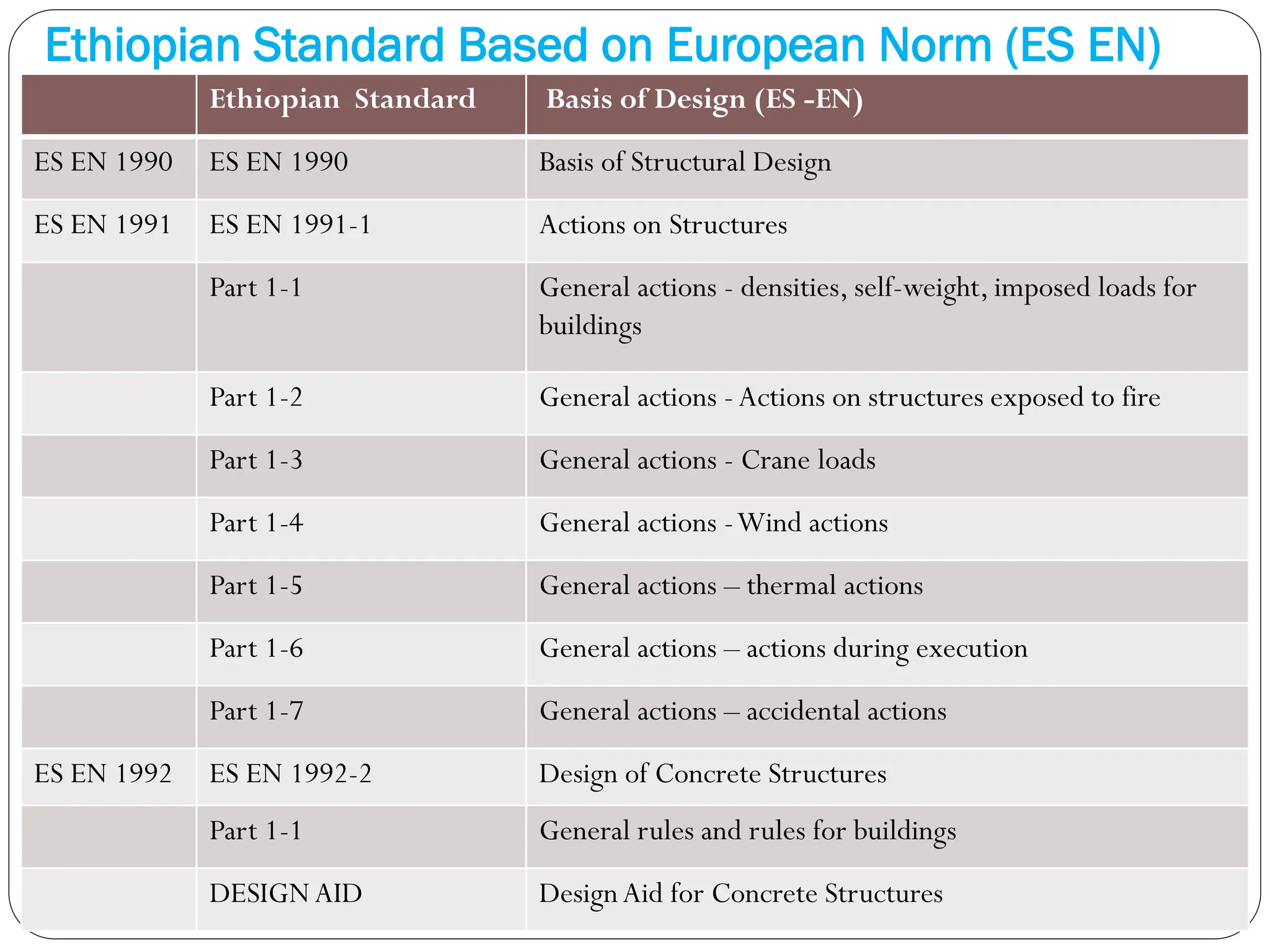

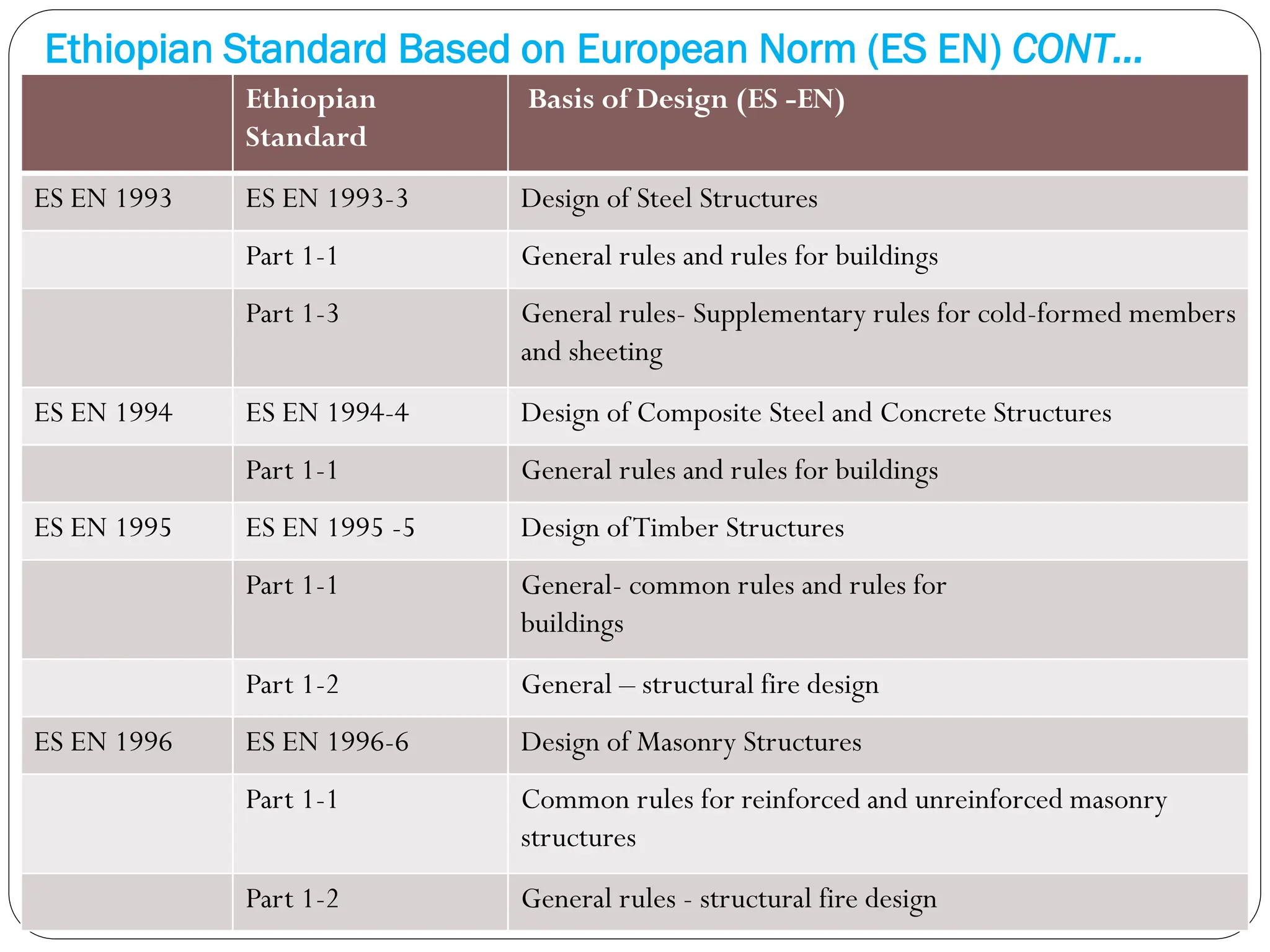

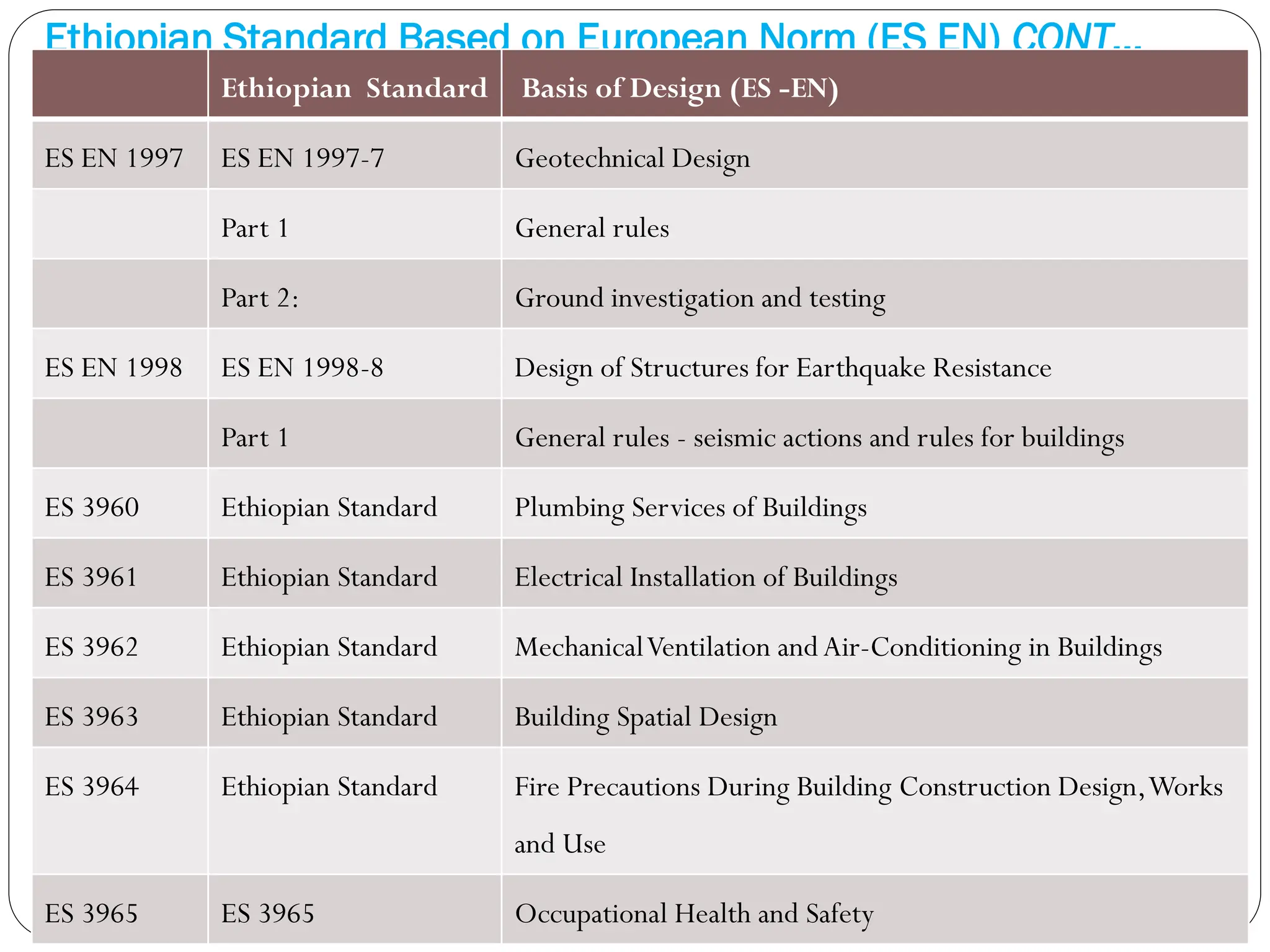

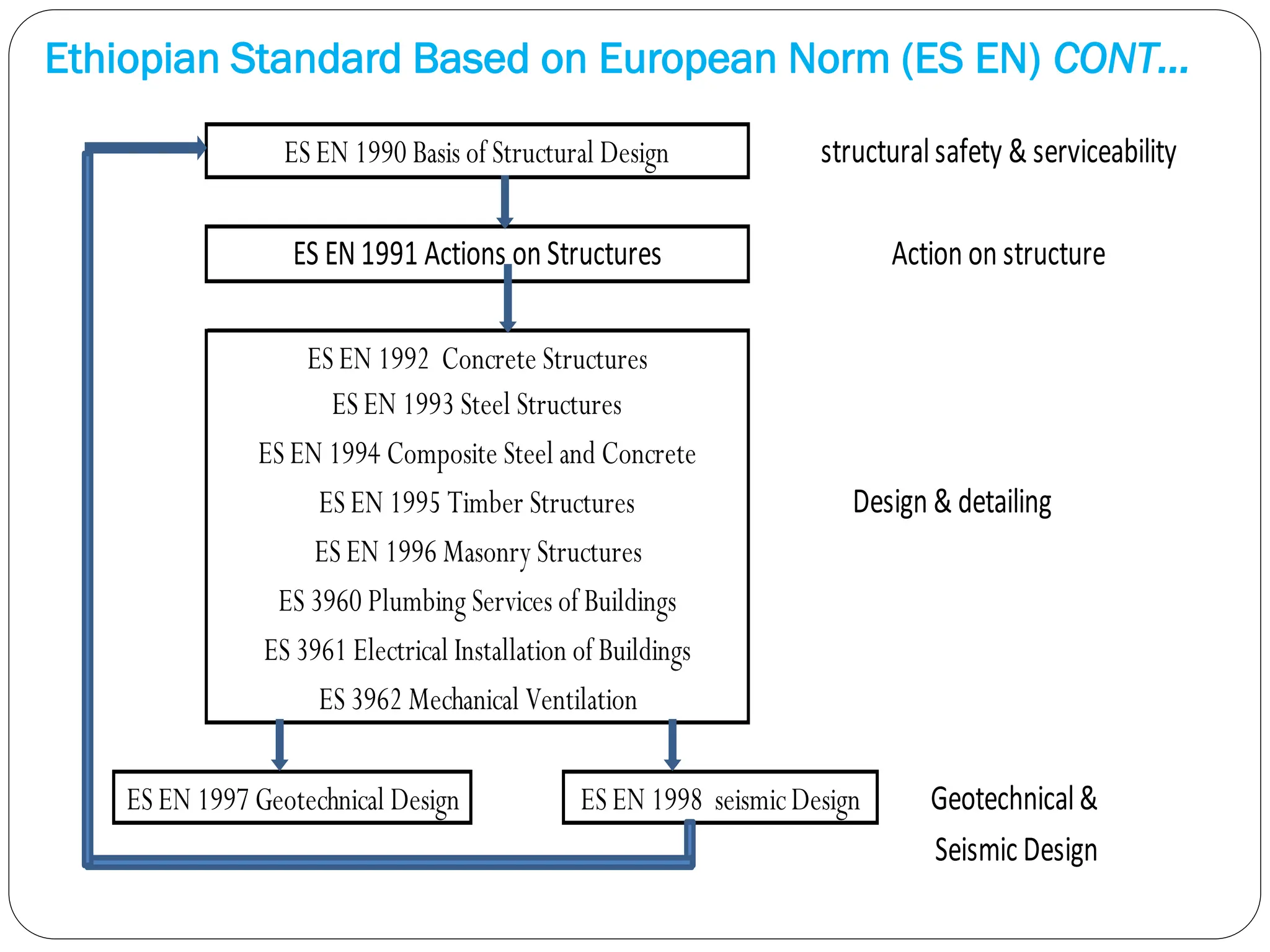

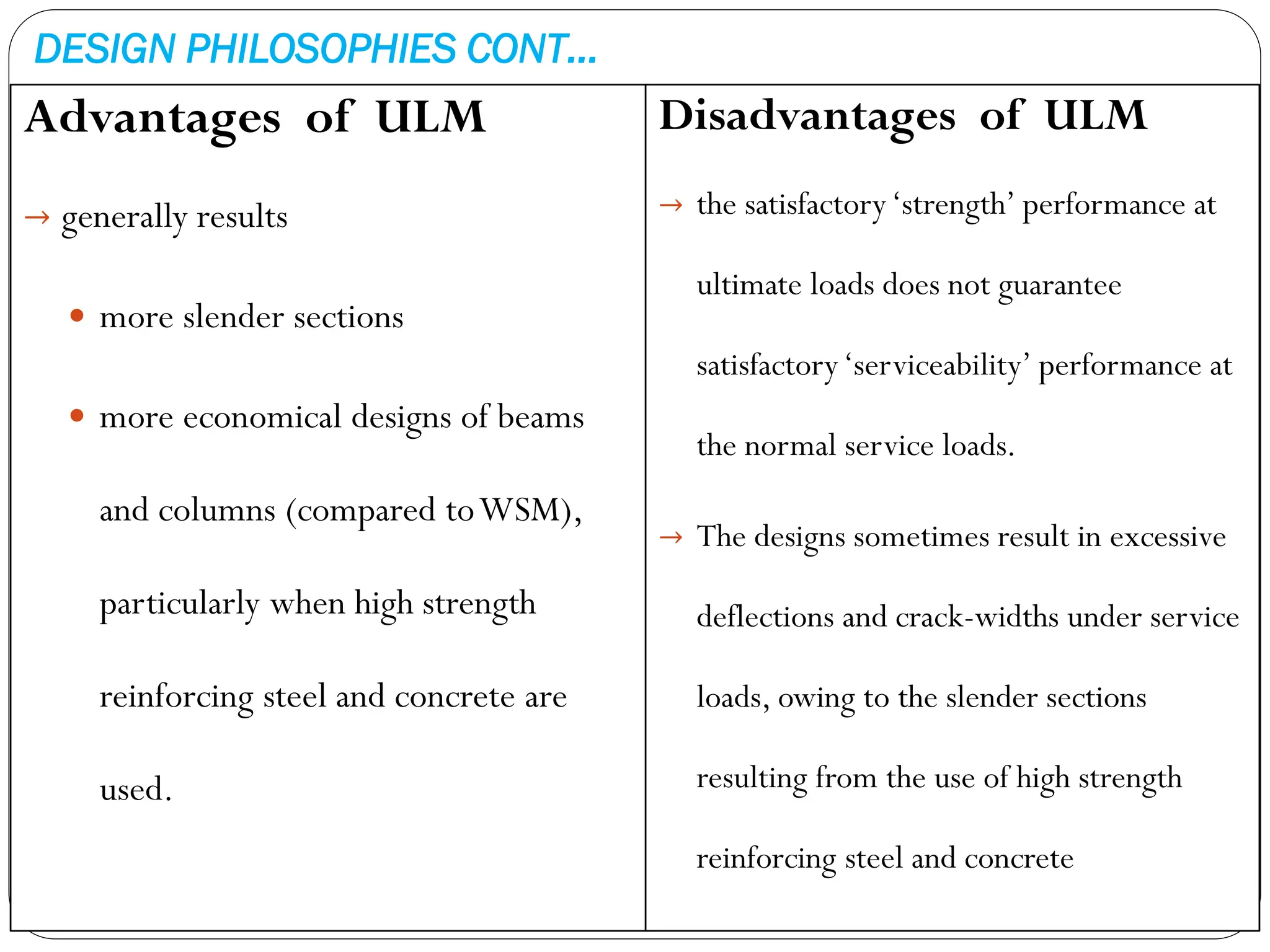

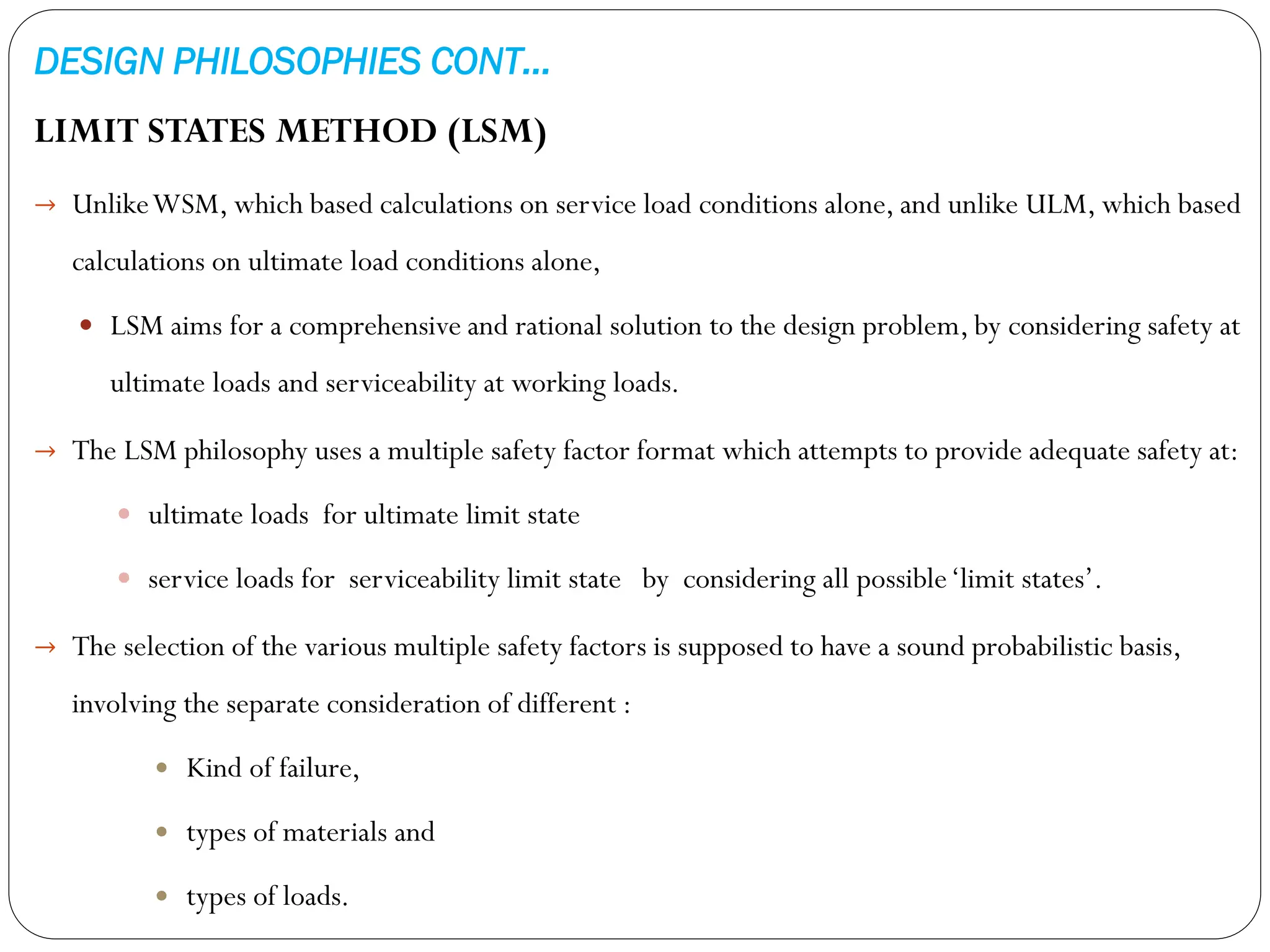

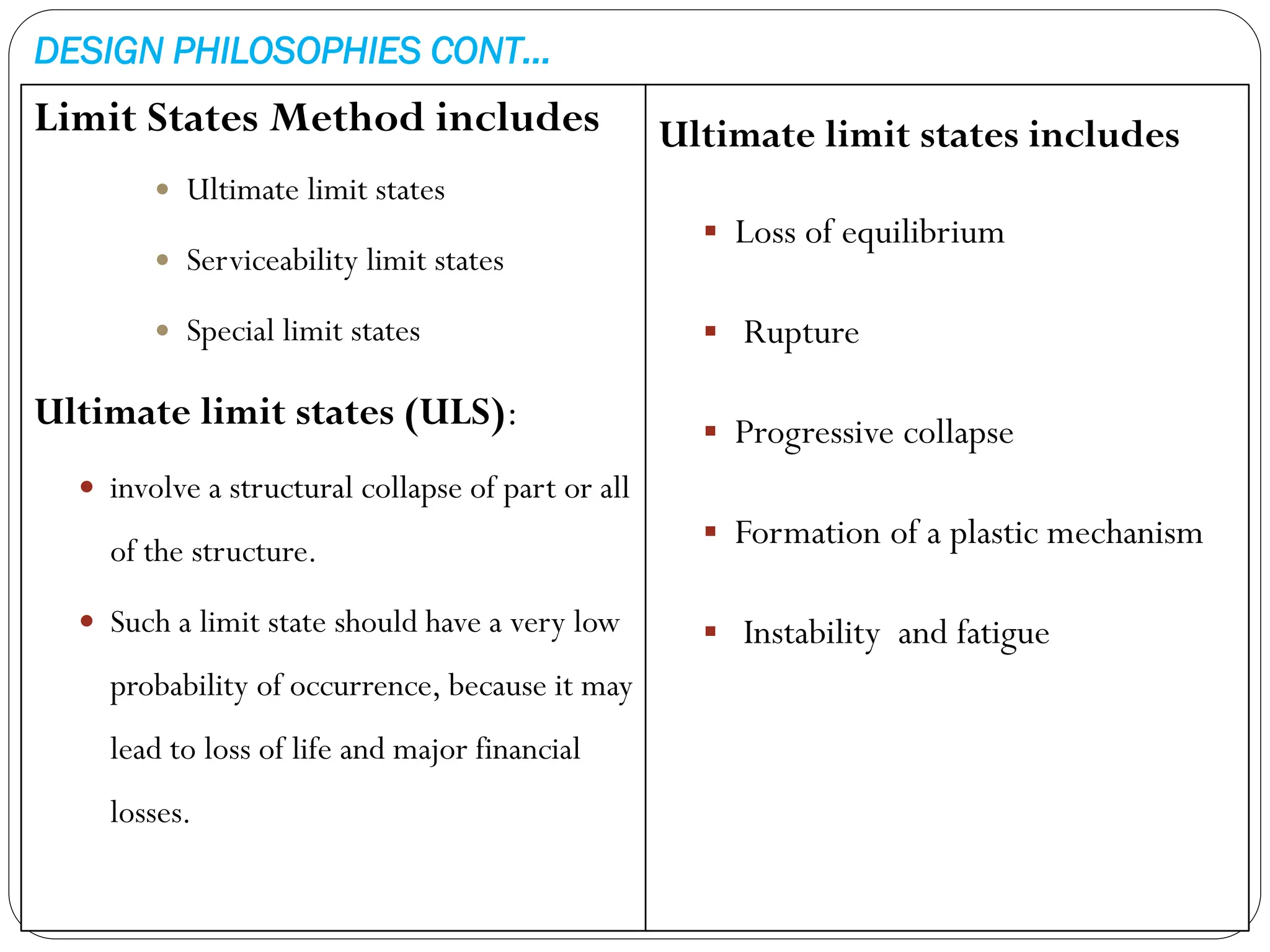

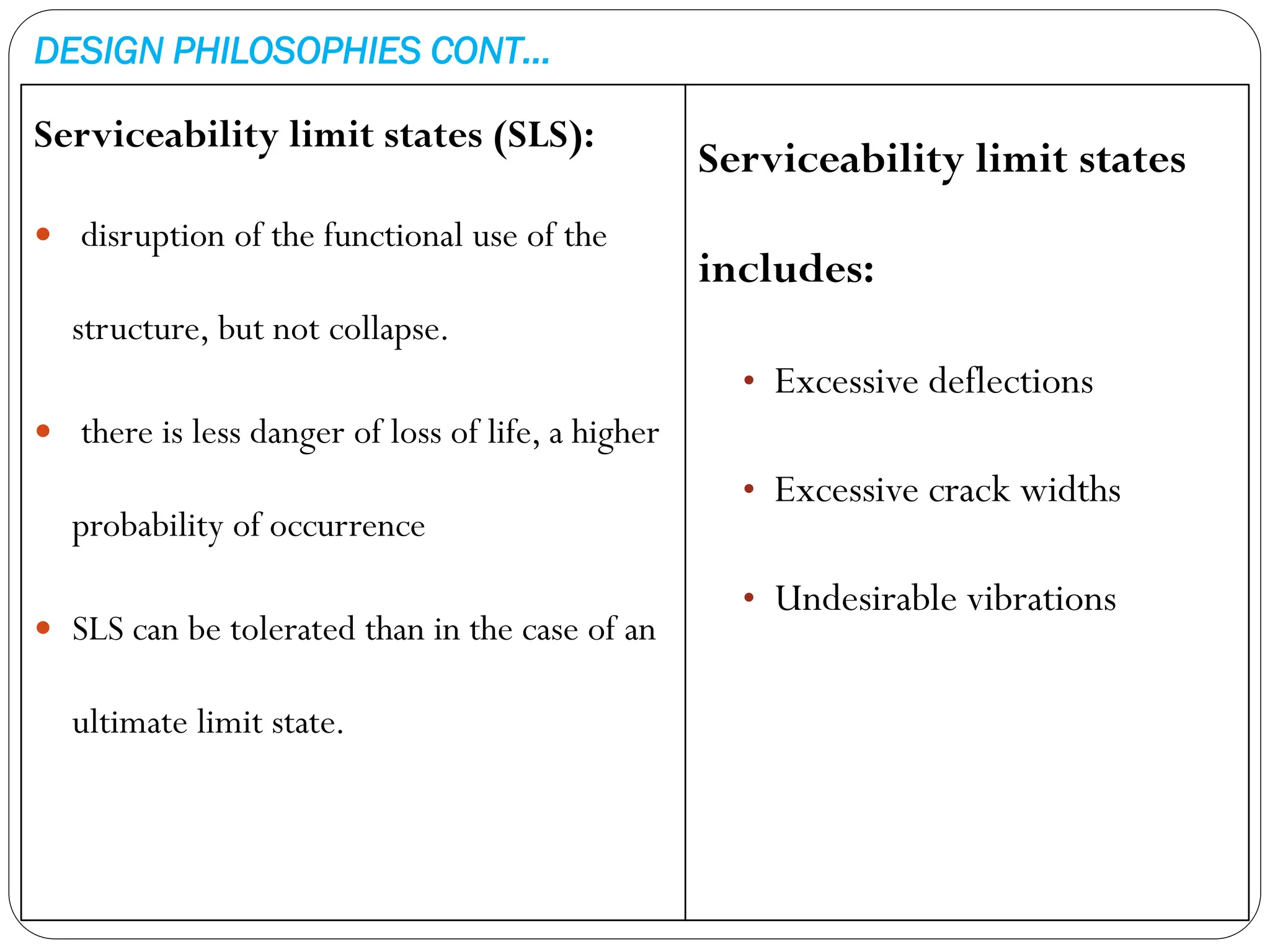

The document provides an introduction to reinforced concrete, discussing the composition, advantages, and applications of concrete and reinforced concrete structures. It outlines the design objectives and process, emphasizing structural safety and adherence to Ethiopian standards based on European norms. Additionally, it covers various design philosophies, including the Working Stress Method, Ultimate Load Method, and Limit States Method, each with its advantages and disadvantages in structural engineering.