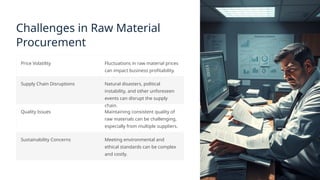

The document discusses the significance of raw materials in producing finished products across various industries, highlighting their types, sourcing processes, quality control measures, and sustainability practices. It covers natural and manufactured raw materials, emphasizes the importance of supplier selection and logistics, and addresses challenges like price volatility and quality issues. Ultimately, it underscores the critical role of efficient procurement and responsible sourcing in business success.