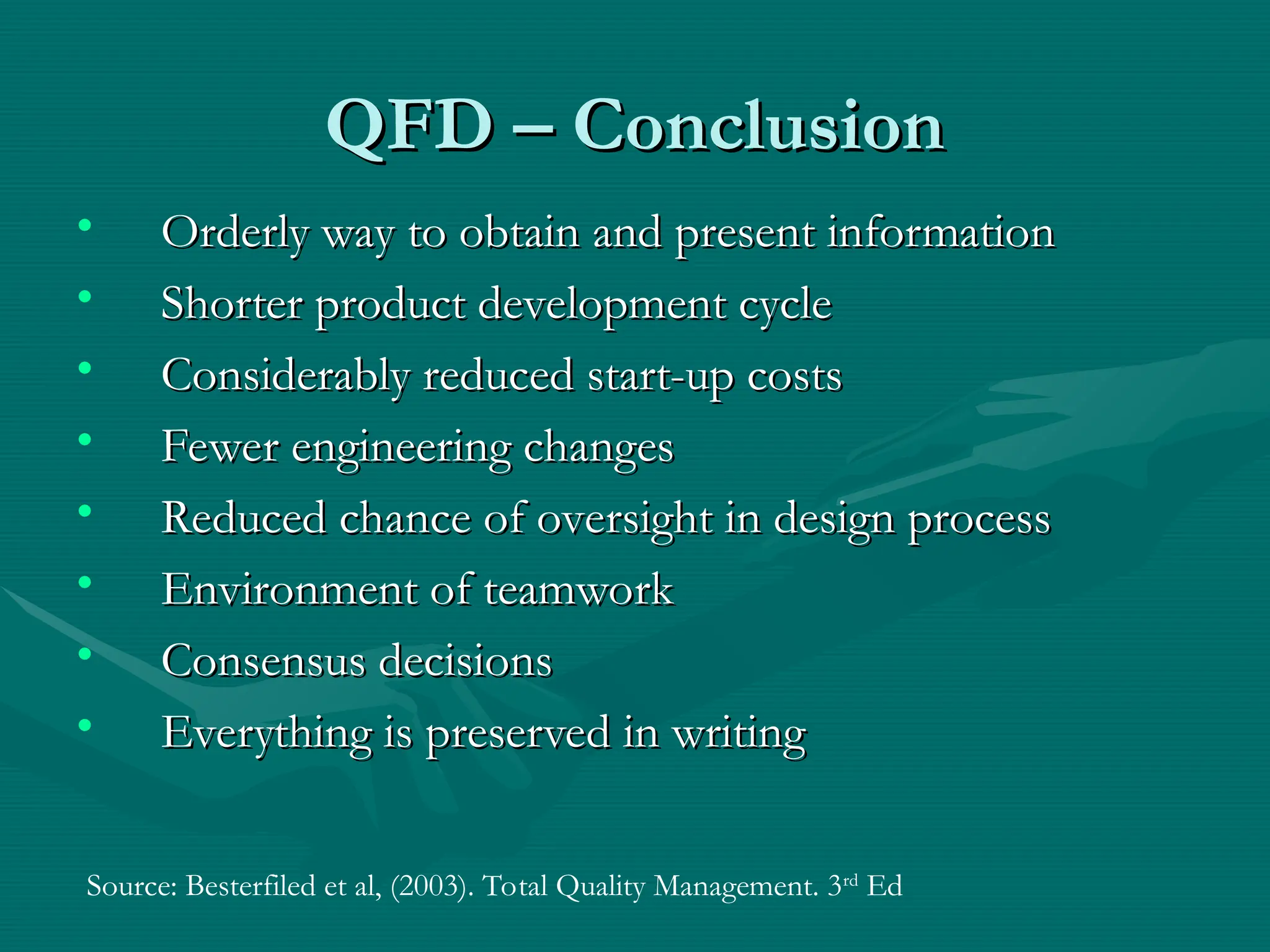

Quality Functional Deployment (QFD) is a team-based planning tool aimed at fulfilling customer expectations by translating them into technical requirements. It involves a structured approach to product and process planning that enhances customer satisfaction, reduces implementation time, and promotes teamwork. The QFD process consists of several steps, including listing customer requirements, developing matrices to assess relationships, and prioritizing customer and technical descriptors to guide product development.