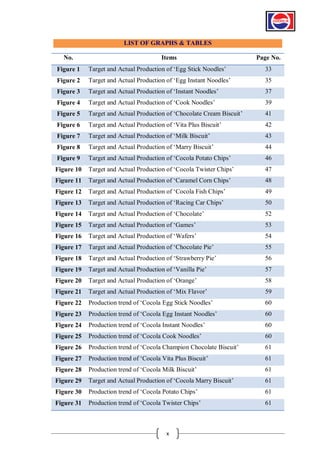

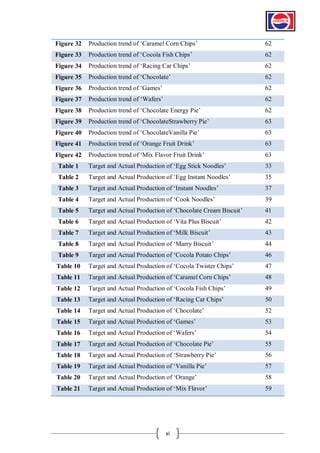

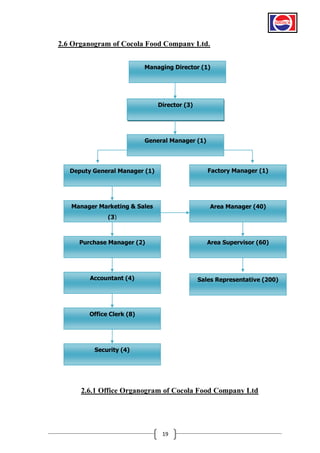

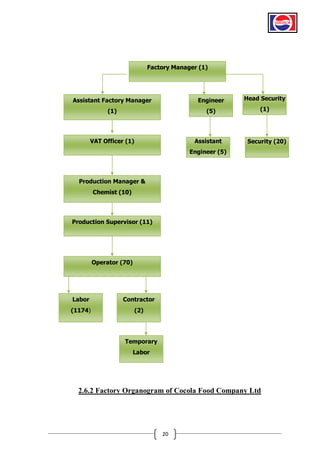

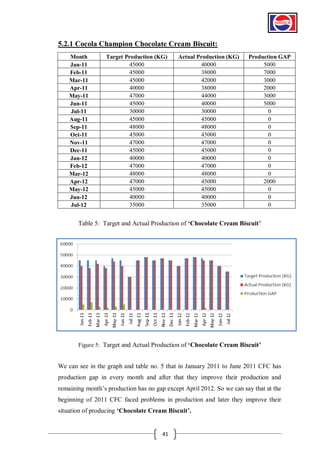

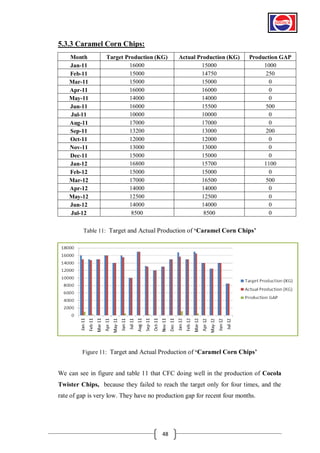

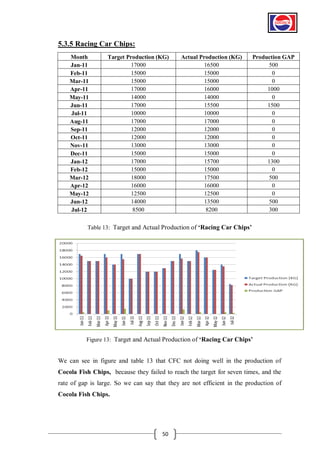

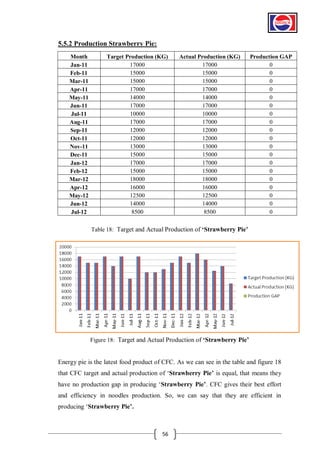

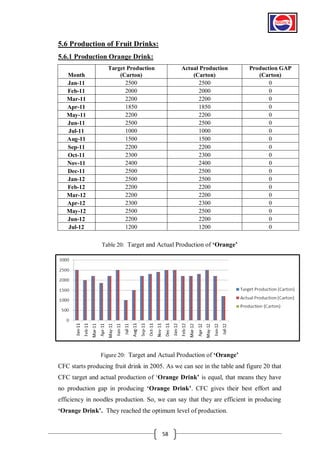

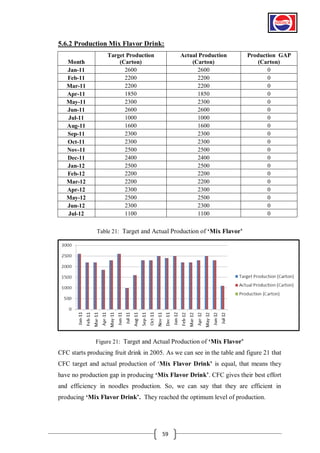

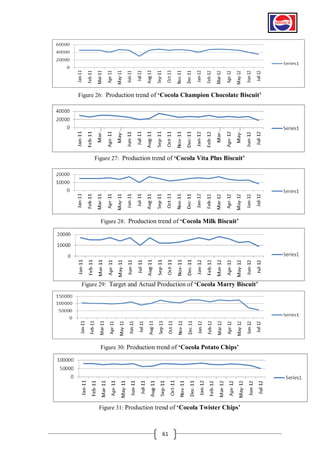

Cocola Food Company Ltd. is a growing private food company in Bangladesh that was established in 1975. The report provides details about Cocola, including its mission, history, products, factory, organizational structure, functional departments, and SWOT analysis. It also analyzes the production efficiency of various Cocola products over time, noting seasonal impacts and identifying reasons for production gaps. Overall, the report finds that Cocola is meeting consumer demand through a wide range of quality food products and playing an important role in the Bangladeshi economy.