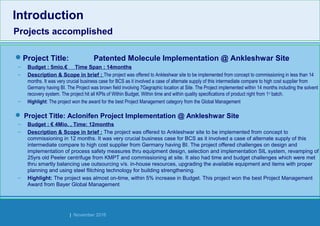

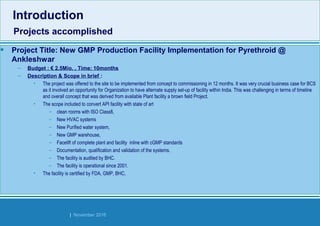

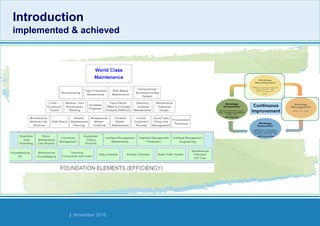

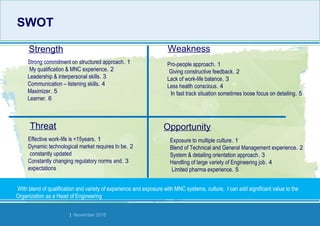

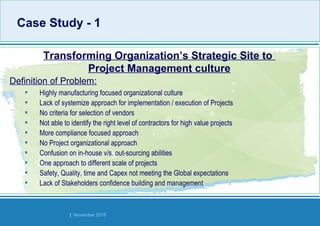

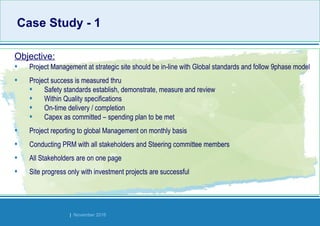

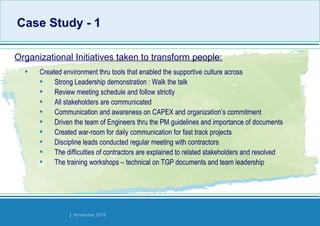

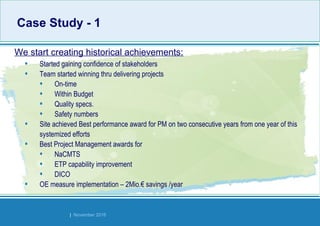

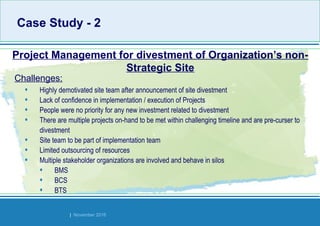

The document outlines the professional experience and achievements of Samir Dave in project management within the chemical and pharmaceutical industries. It highlights his extensive background in managing significant capital investment projects, implementing organizational transformations, and executing various successful initiatives while emphasizing safety, quality, and timely delivery. Additionally, it discusses case studies demonstrating the effective management of projects related to divestment and the development of a project management culture across organizations.