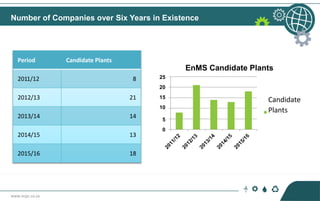

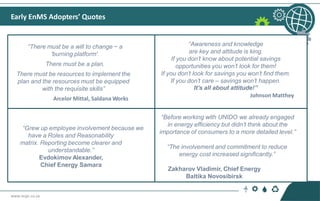

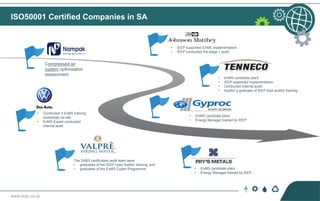

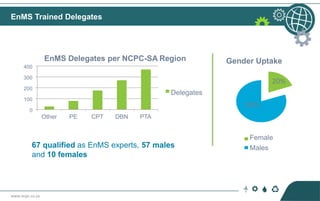

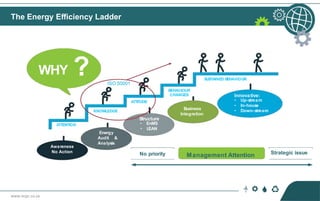

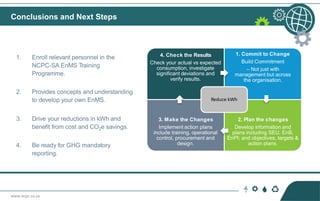

This document summarizes South Africa's progress with implementing energy management systems (EnMS) based on ISO 50001 since 2011. It notes that 74 companies have implemented EnMS over six years, with benefits including cost savings. It also discusses changes made to the EnMS training program, like strengthening company selection criteria and providing more support for small businesses. The presentation concludes by encouraging participants to enroll in EnMS training to develop their own system and reduce energy use.