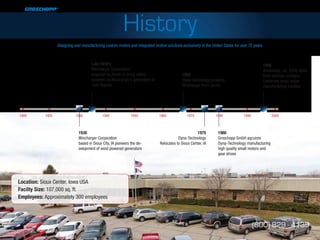

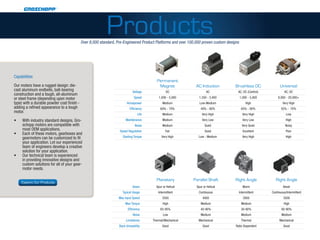

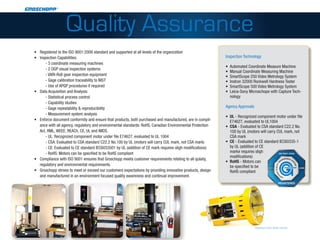

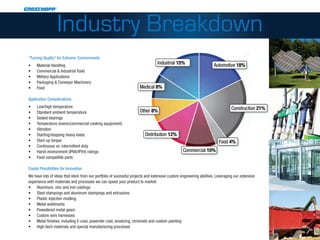

Groschopp Inc. is a manufacturer of custom motors, gearmotors and reducers located in Sioux Center, Iowa. They have over 75 years of experience designing and manufacturing exclusively in the US. Their products include over 8,000 standard platforms and 100,000 custom designs. They ensure high quality through ISO 9001 registration and inspection capabilities including 3D measurement machines.