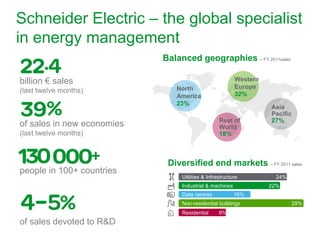

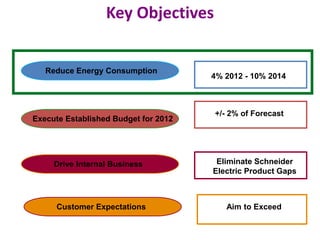

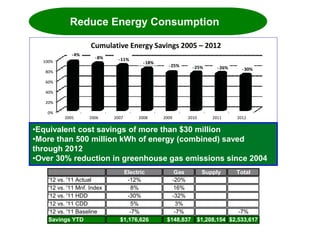

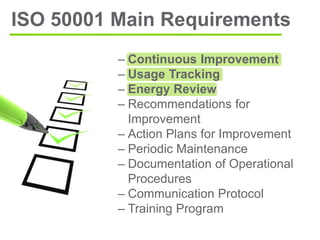

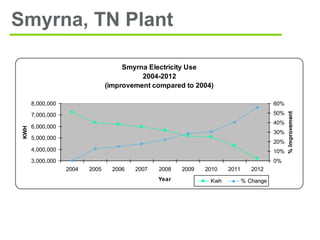

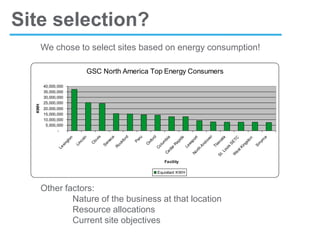

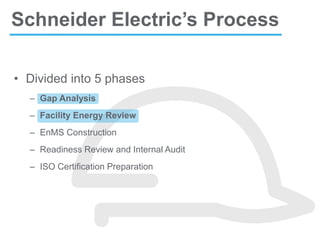

This document provides an overview of Schneider Electric's experience with ISO 50001 energy management system certification. It discusses why Schneider Electric pursued ISO 50001 certification, details of their initial pilot project to certify their world headquarters, and the requirements and benefits of certification. It also reviews Schneider Electric's existing energy management program, goals, and results in reducing energy consumption and greenhouse gas emissions across their facilities. The future plans under ISO 50001 to further improve energy performance are mentioned.