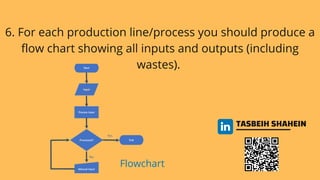

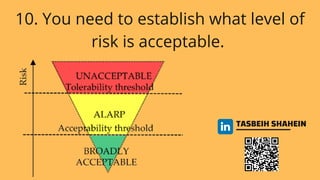

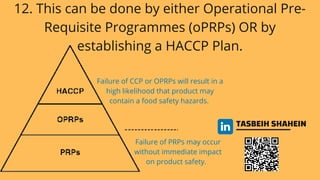

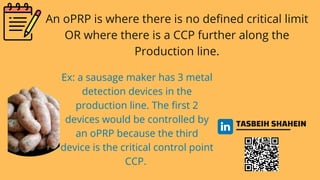

This document outlines the 16 steps to implement an ISO 22000 food safety management system. The steps include appointing a food safety team, establishing prerequisite programs, developing specifications for raw materials and end products, identifying food safety hazards, establishing acceptable risk levels, validating and implementing control measures to address risks, and periodically verifying controls. Key aspects are analyzing processes through flowcharts, using a repeatable methodology like the Codex decision tree to select controls, and validating that controls lower hazards below acceptable levels.