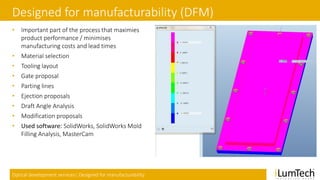

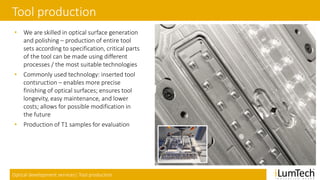

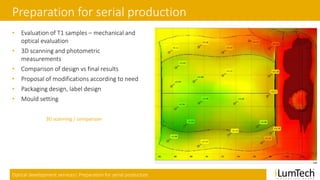

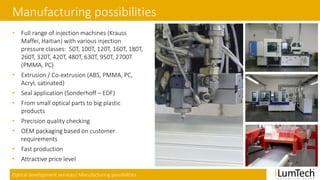

Ilumtech offers comprehensive optical development services, including tailored design of optical components such as lenses and reflectors, rapid prototyping, and optical system optimization. Their process involves creating 3D models, selecting optical materials, and ensuring manufacturability, with a focus on meeting customer specifications and deadlines. The company utilizes advanced software and tools for mechanical design, prototyping, and manufacturing, aiming to deliver high-quality optical solutions efficiently.