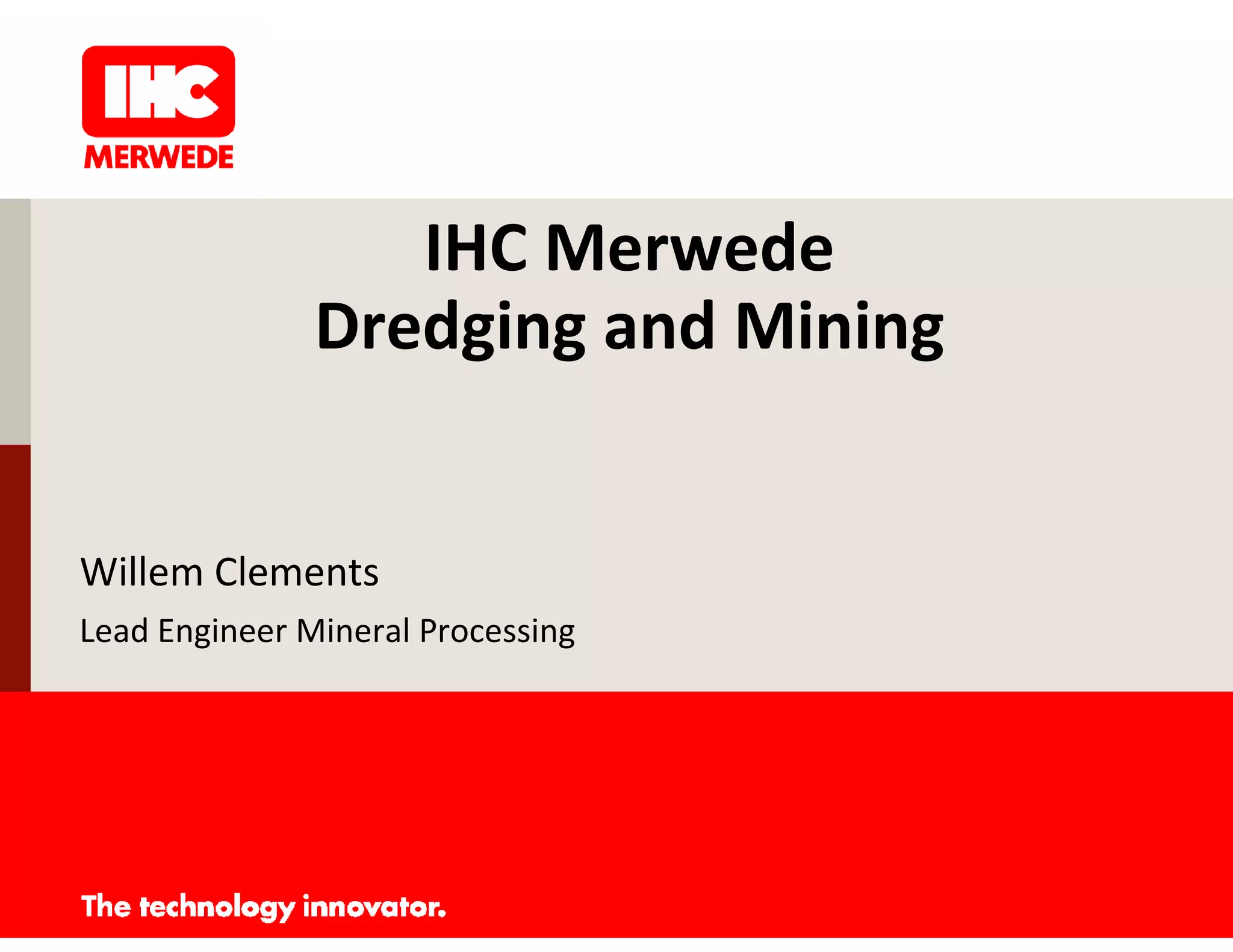

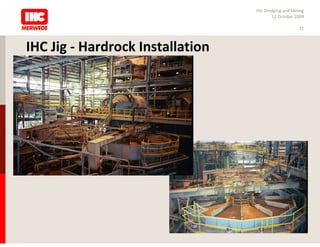

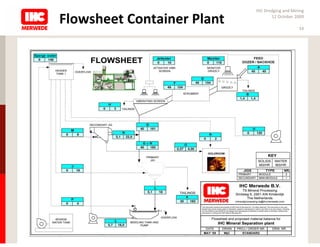

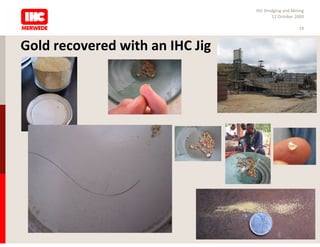

The document discusses dredging and mineral processing equipment from IHC, including trailing suction hopper dredges, bucket chain ladder dredges, bucket wheel dredges, cutter suction dredges, and IHC jigs. IHC jigs can be used for land-based, floating, and hardrock mineral installations, as well as in standard container plants. The document highlights the advantages of IHC jigs, such as their excellent recovery rates and ability to separate fine mineral grains. In conclusion, IHC offers comprehensive packages for alluvial mining and is a "one stop shop" for mining studies, wet excavation equipment, mineral processing equipment, and control solutions.