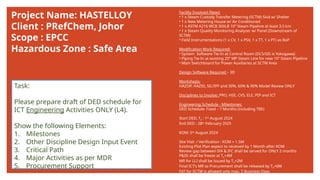

The document outlines the workflow and scheduling for ICT engineering in industrial processes, detailing key stages such as project initiation, design, procurement, construction, and commissioning. It specifies the necessary activities and milestones for a project named 'Hastelloy' involving steam custody transfer metering and other modifications. The timeline includes fixed milestones and critical elements for each stage, highlighting resource allocation and inter-dependencies.