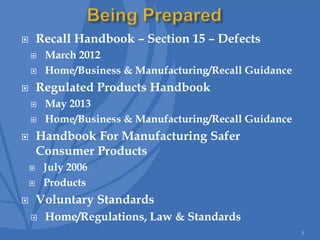

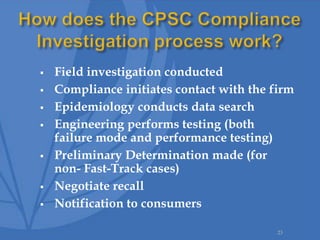

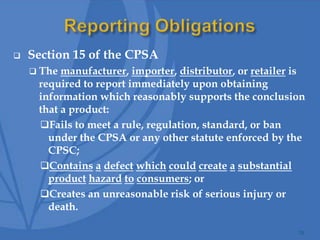

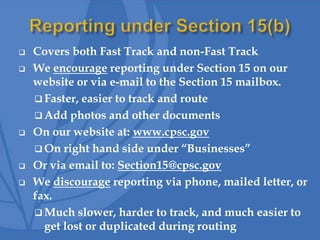

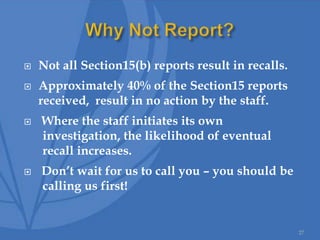

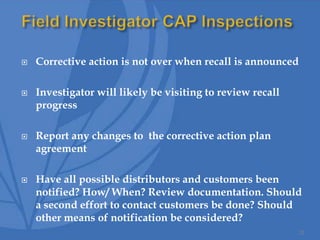

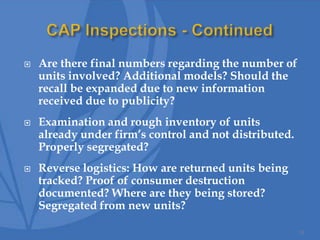

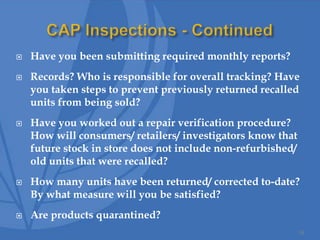

This document provides an overview and guidance for firms on consumer product recalls and CPSC compliance. It discusses the recall process, from initial reporting of a potential defect to ongoing monitoring and disposal of recalled products. Firms are advised to maintain thorough records, cooperate with CPSC staff, and make comprehensive efforts to reach all consumers regarding recalls. The presentation also provides an overview of CPSC's authorities and resources for firms to aid compliance.