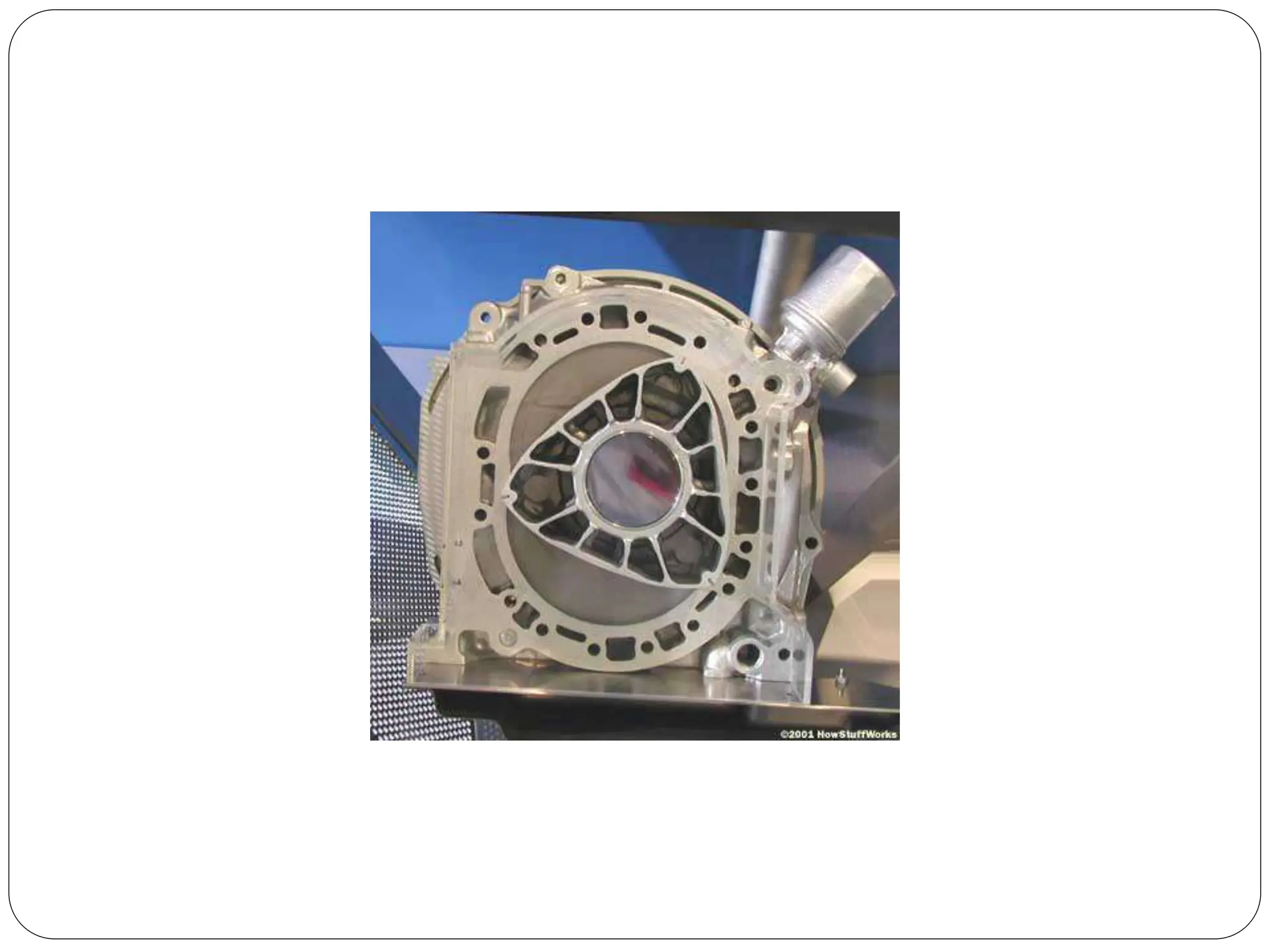

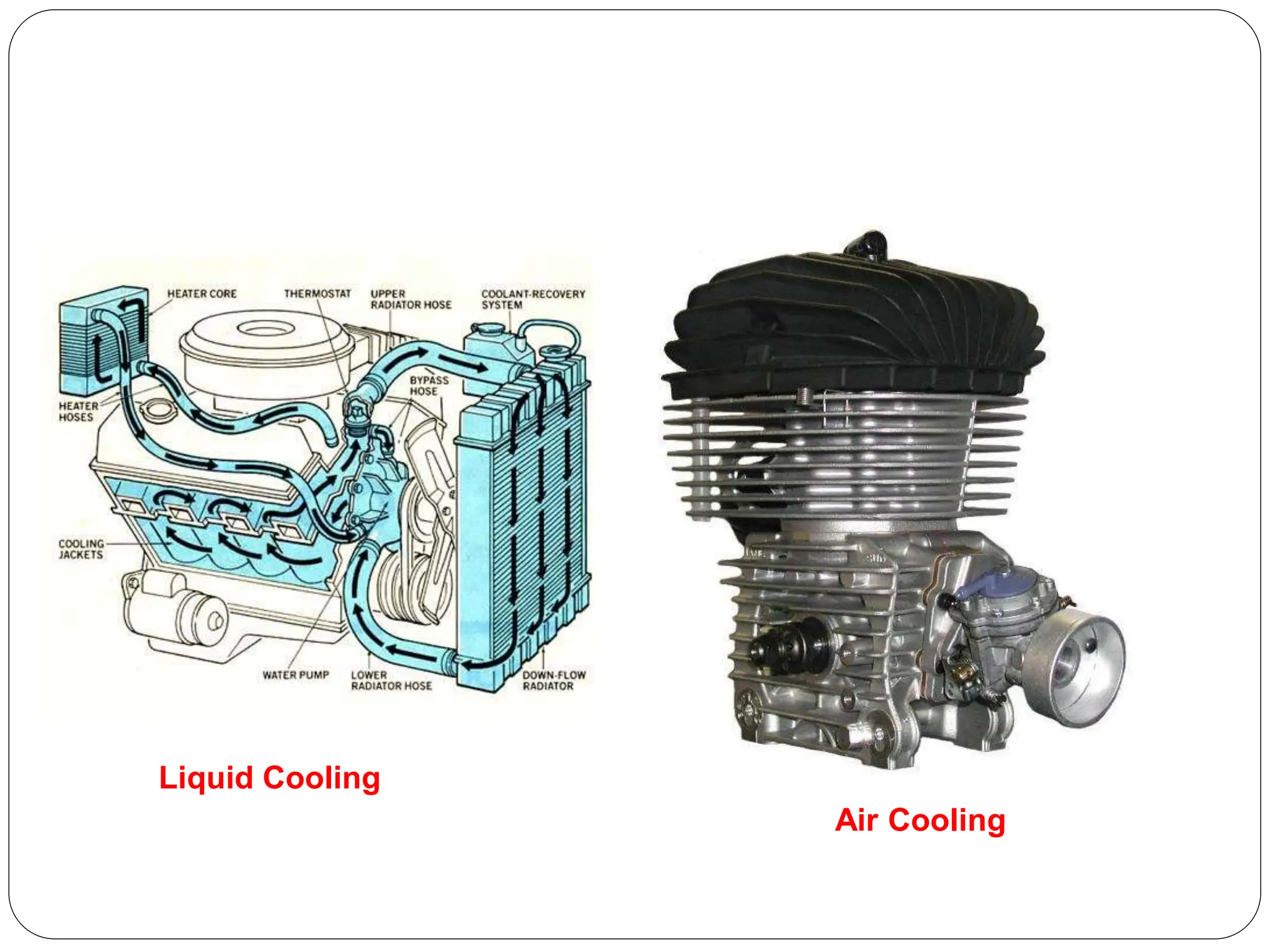

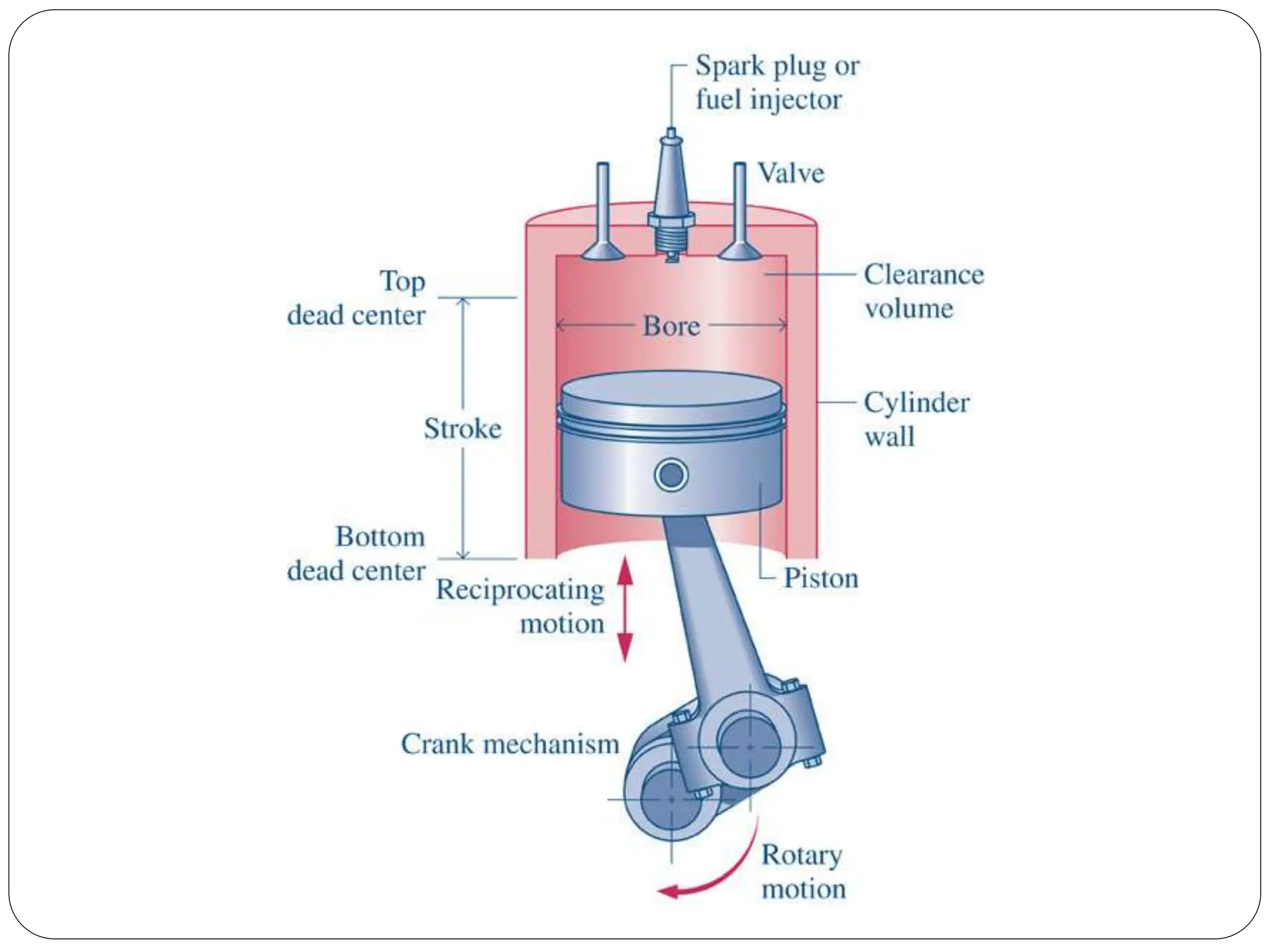

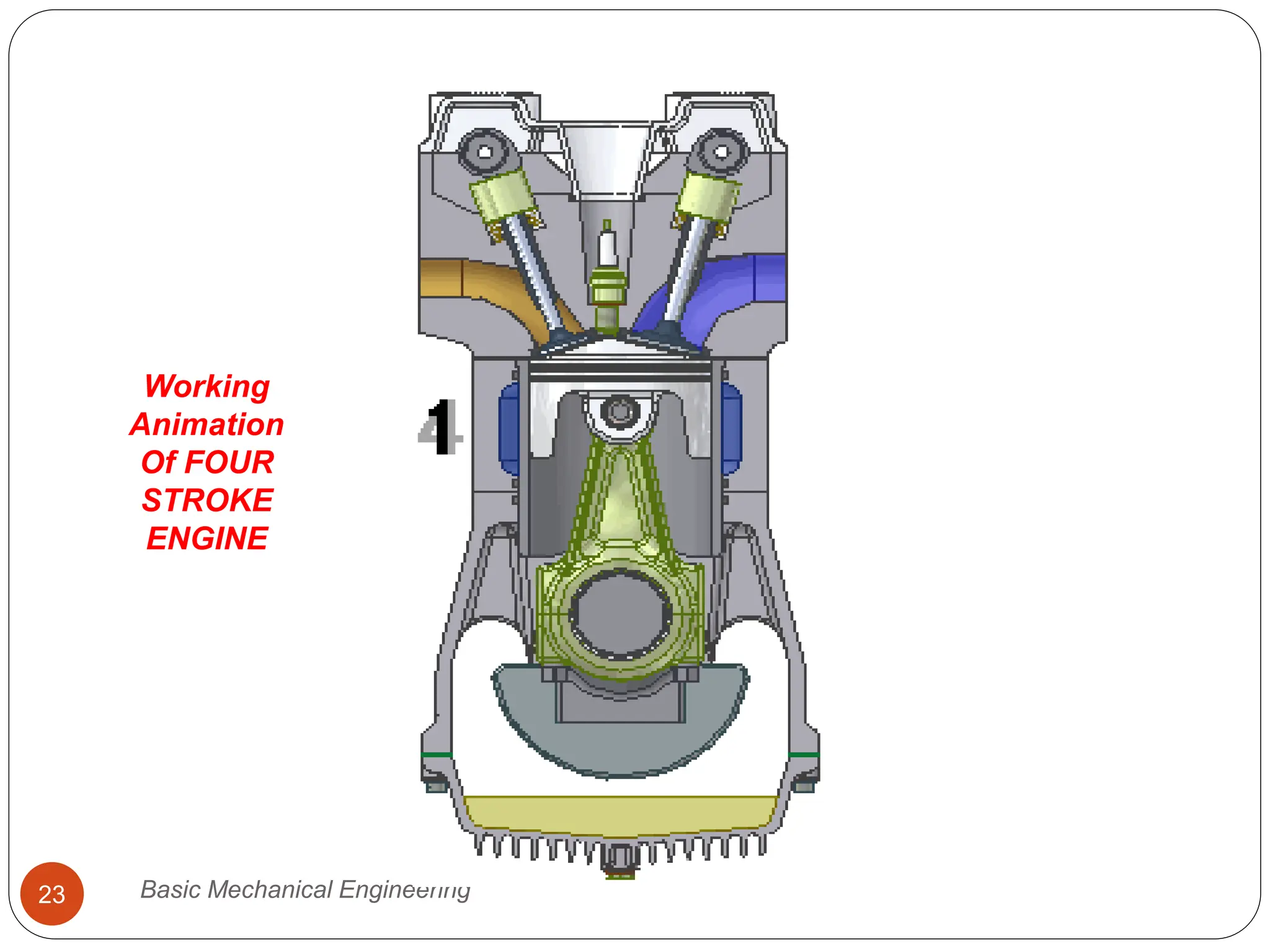

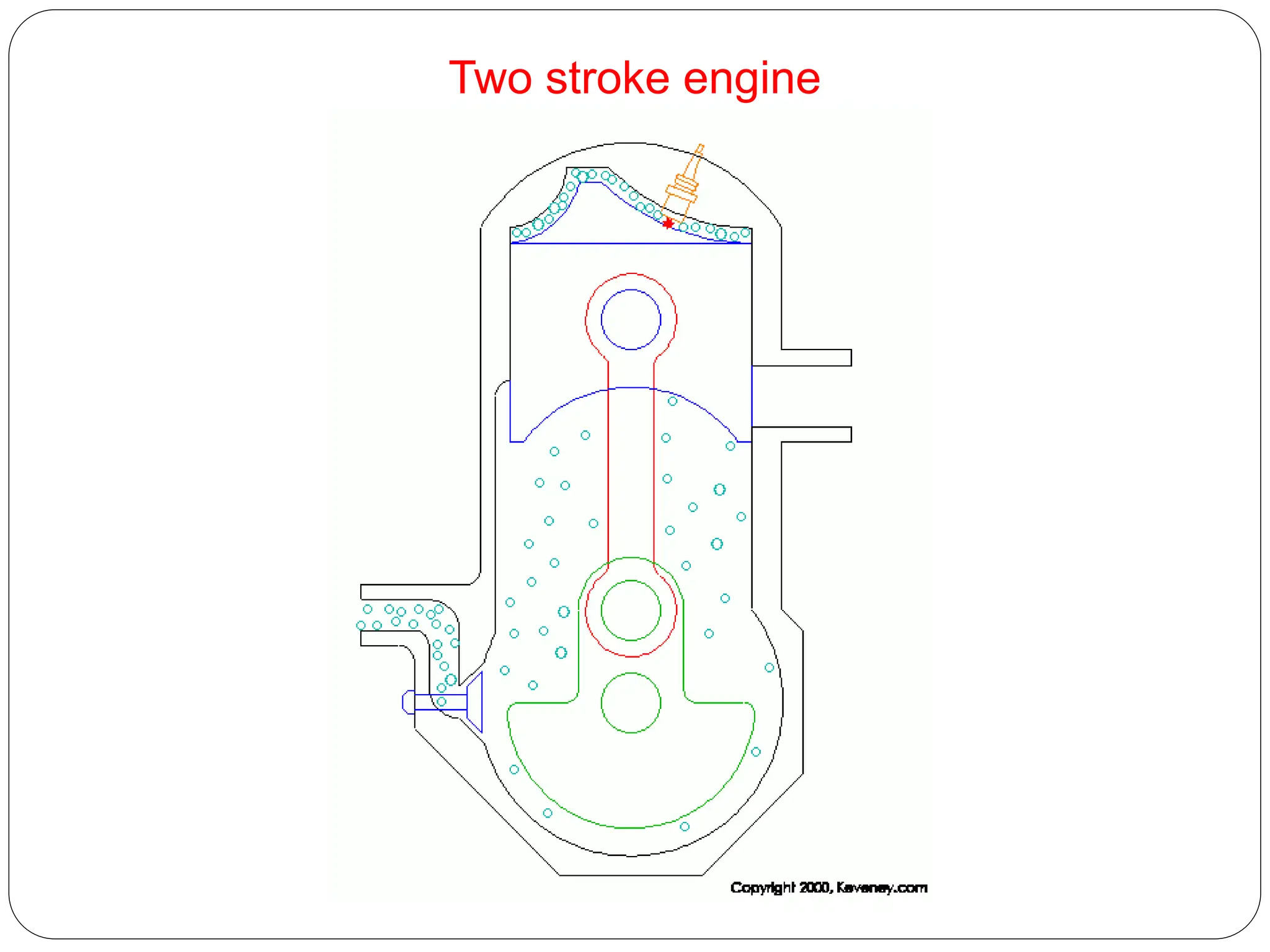

The document provides an in-depth overview of internal combustion (IC) engines, detailing their components such as the cylinder, piston, connecting rod, and crankshaft, along with their materials and manufacturing methods. It categorizes IC engines based on ignition type, cycle (four-stroke and two-stroke), valve location, and cooling methods, while also explaining the working principles of both engine cycles and their efficiencies. Furthermore, it addresses factors affecting engine performance, including fuel-air mixture, dissociation, and the impact of various cycles on efficiency.