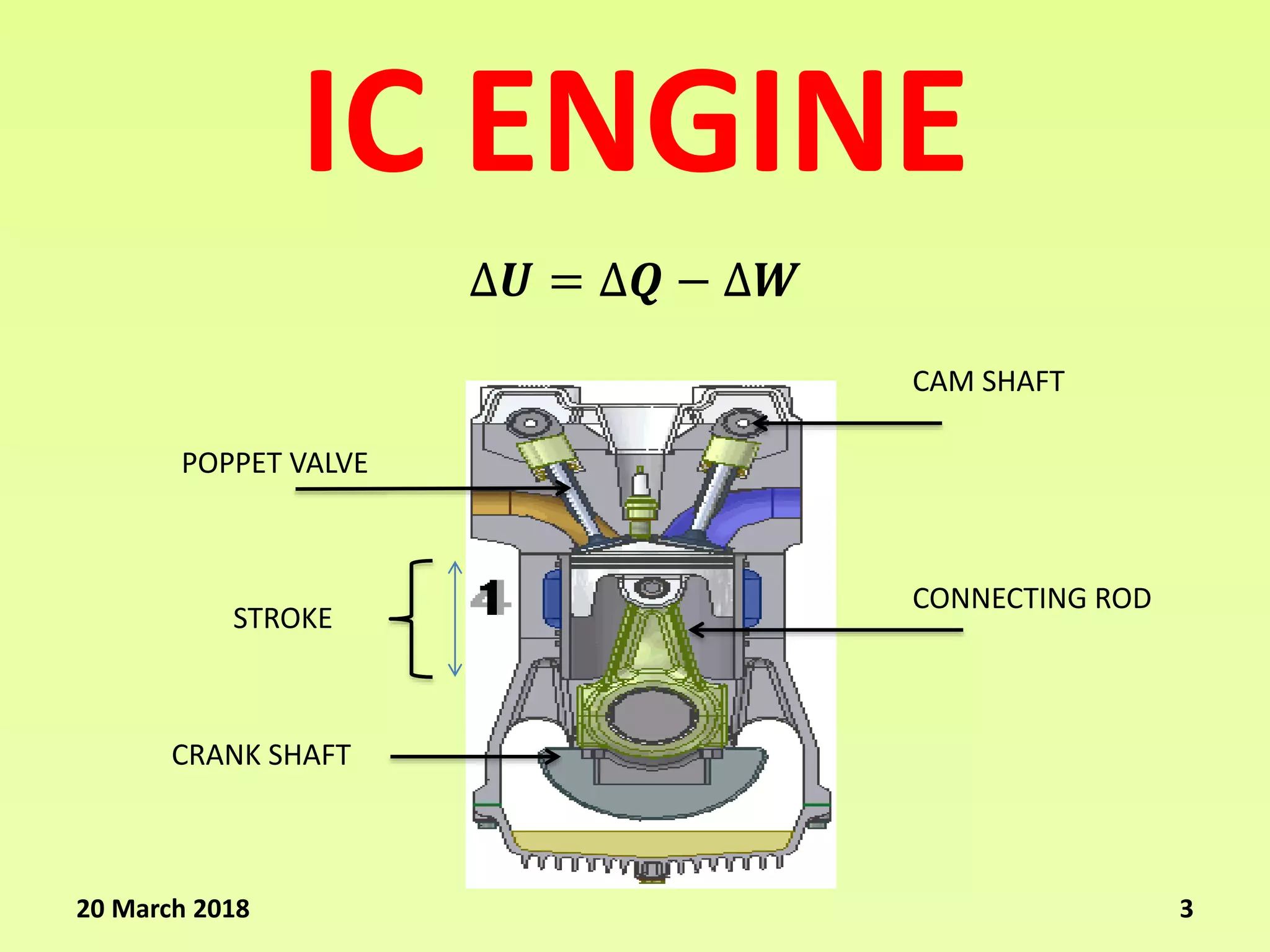

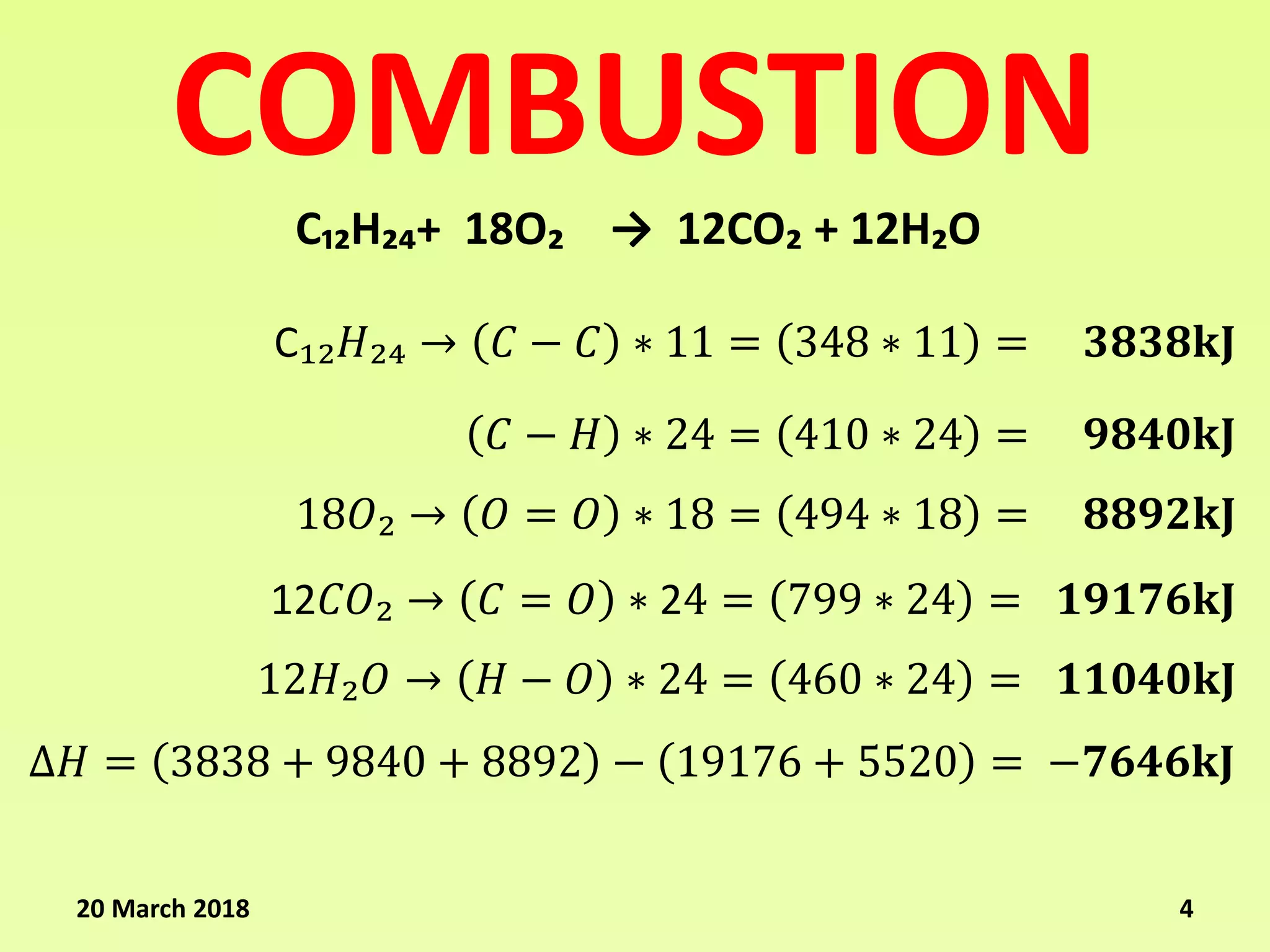

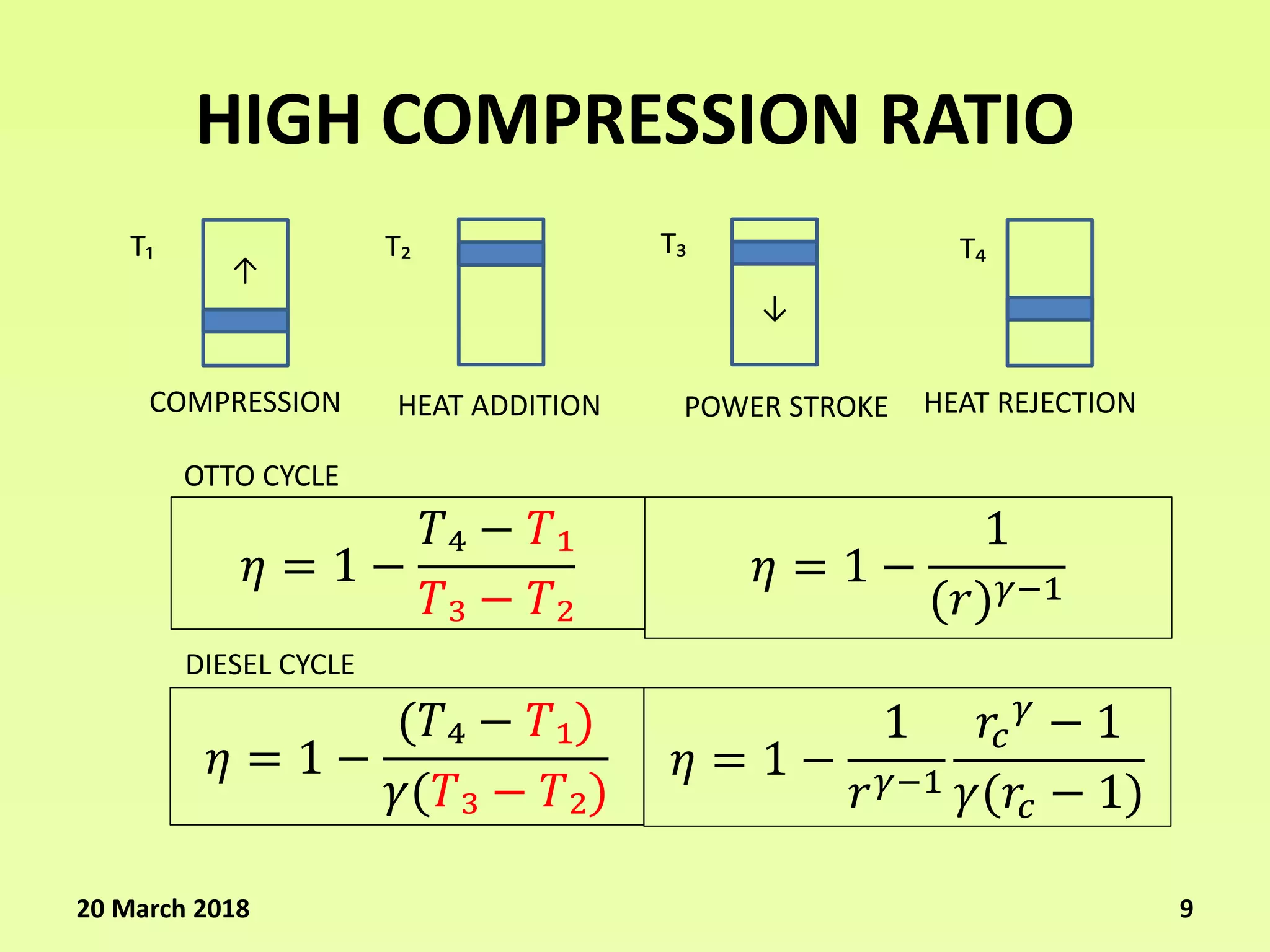

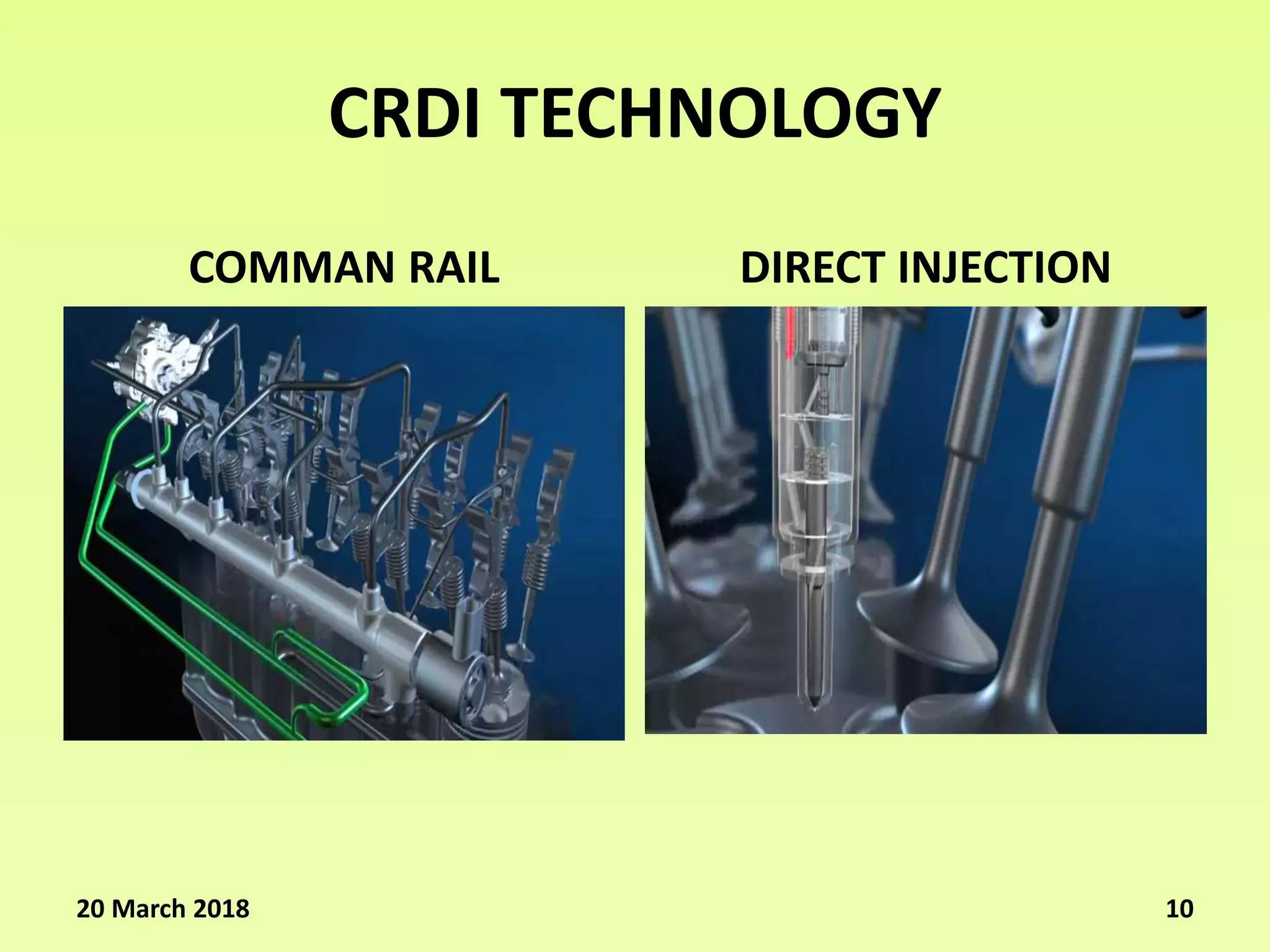

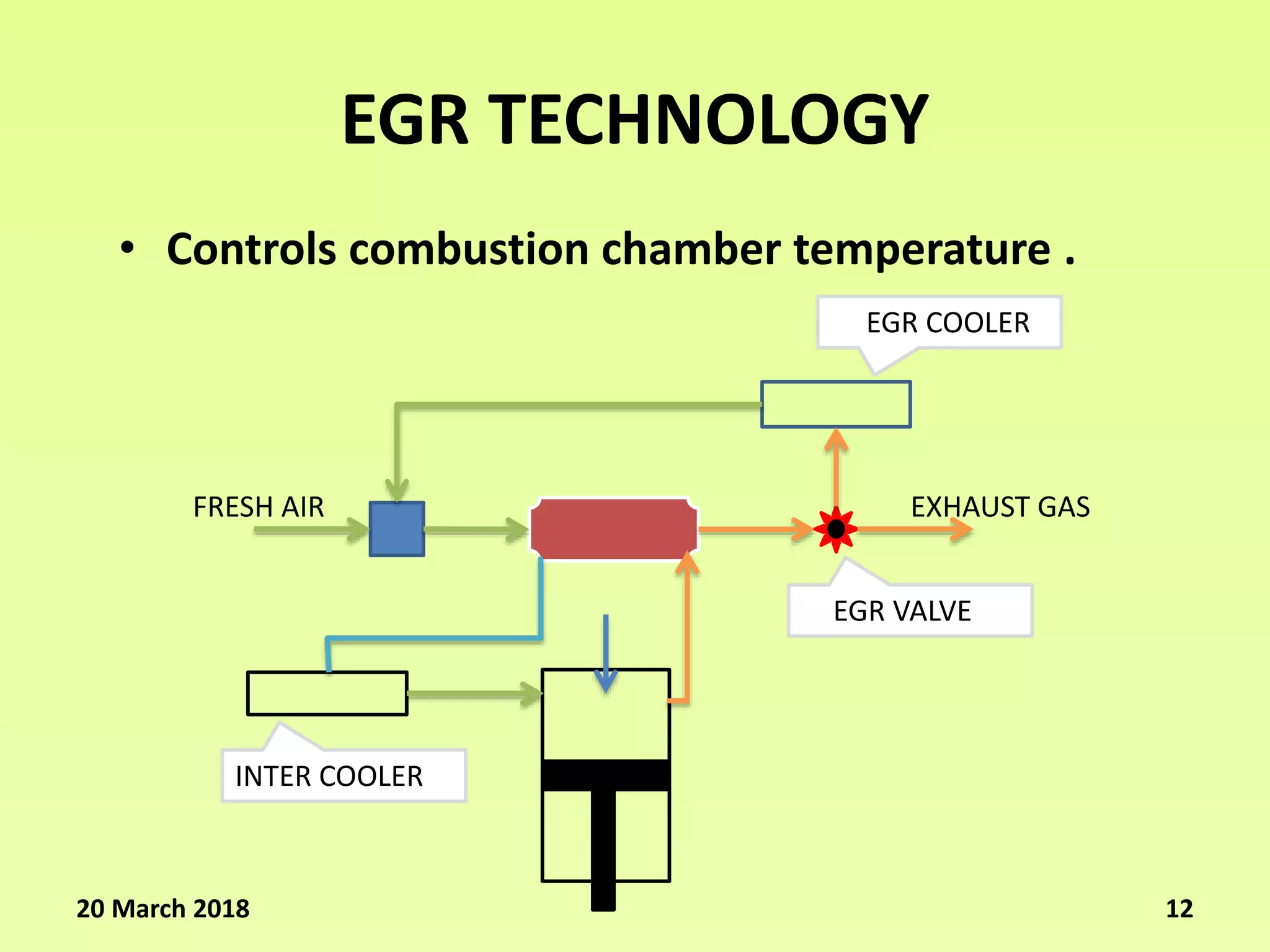

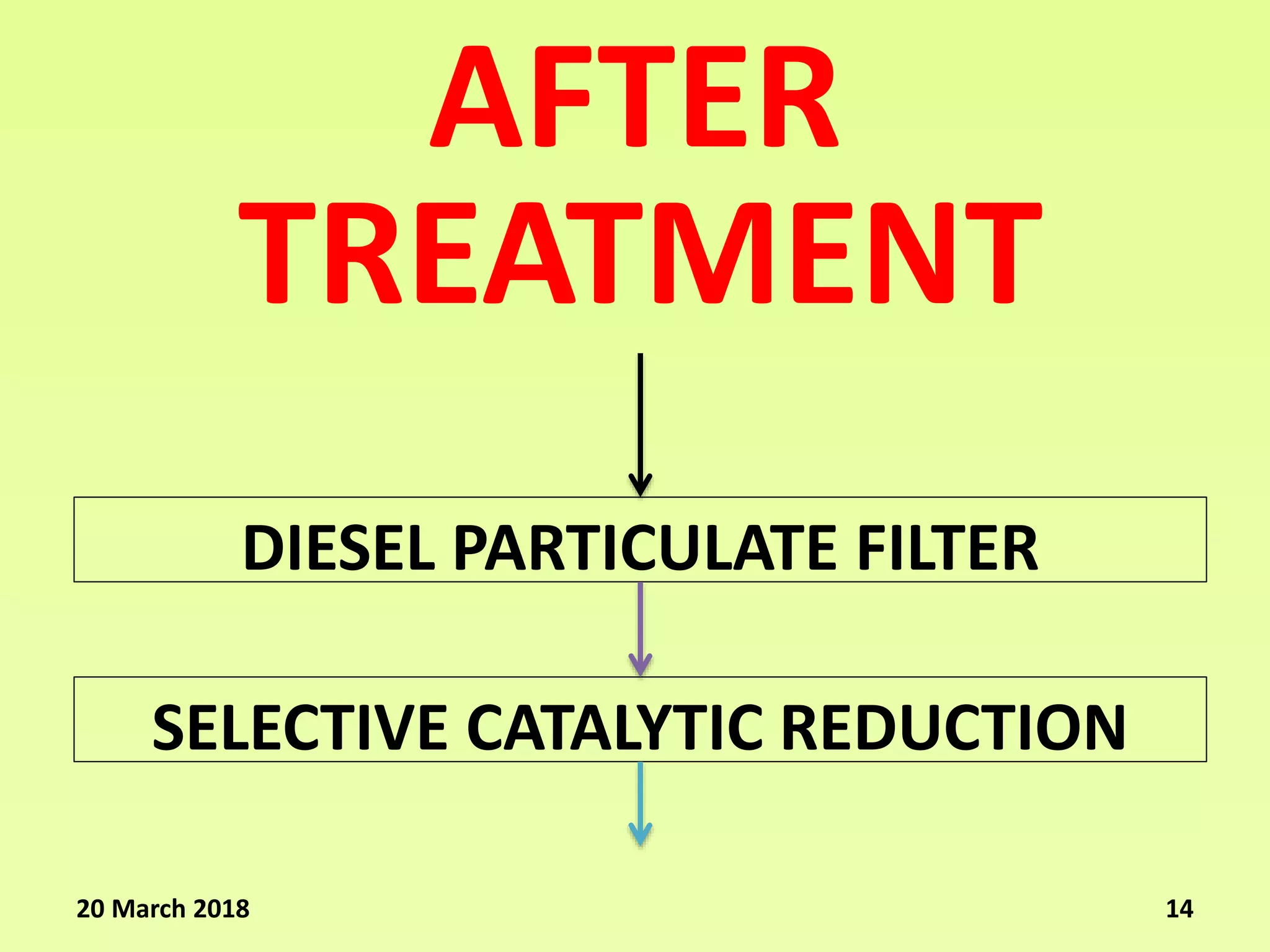

This document discusses internal combustion engines and emission control technologies. It begins with an introduction to combustion and the emissions produced from internal combustion engines. It then describes advancements in engine technology, such as common rail direct injection, turbochargers, exhaust gas recirculation, and electronic control units that have improved engine efficiency. The document also discusses after-treatment technologies like diesel particulate filters and selective catalytic reduction systems that reduce emissions exiting the engine. It concludes by noting both the benefits of these technologies in reducing emissions as well as their drawbacks such as increased costs.