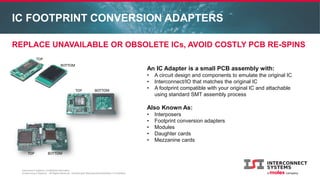

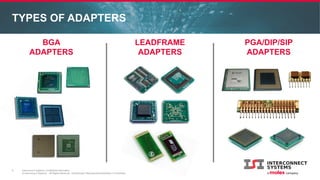

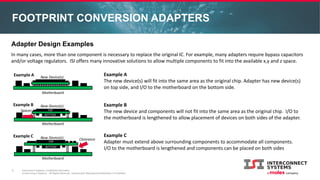

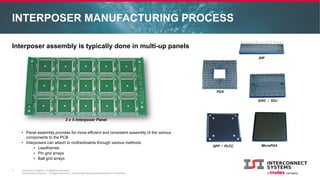

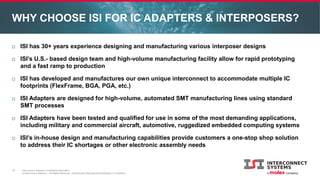

The document outlines solutions for IC obsolescence and shortages, primarily through the use of IC adapters and interposers that replace or emulate obsolete integrated circuits. It details the design and manufacturing process of these adapters, emphasizing their benefits in avoiding costly redesigns and facilitating efficient PCB assembly. Additionally, the document discusses ISI's capabilities in reballing and reclaiming components to extend their lifecycle and meet specific customer requirements.