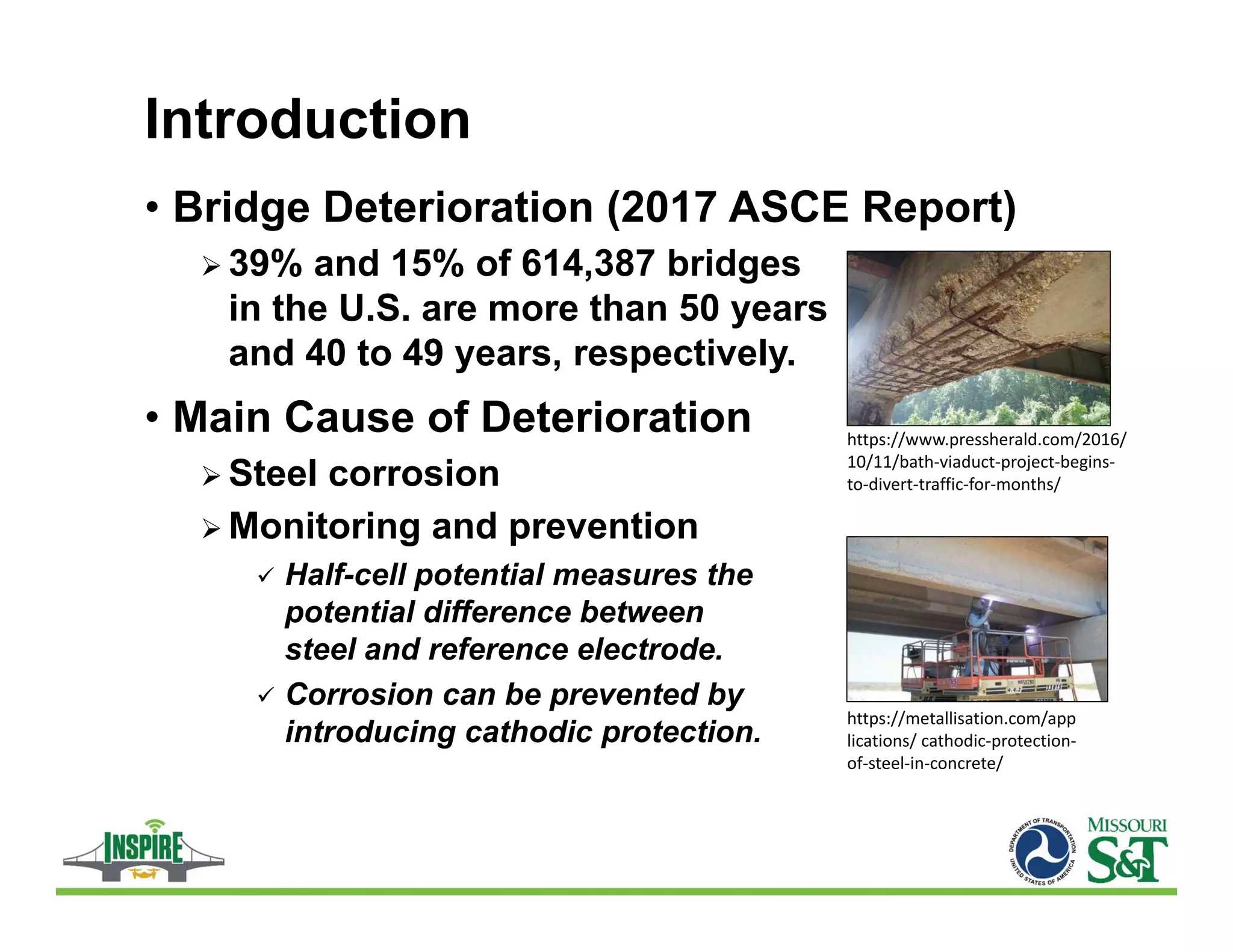

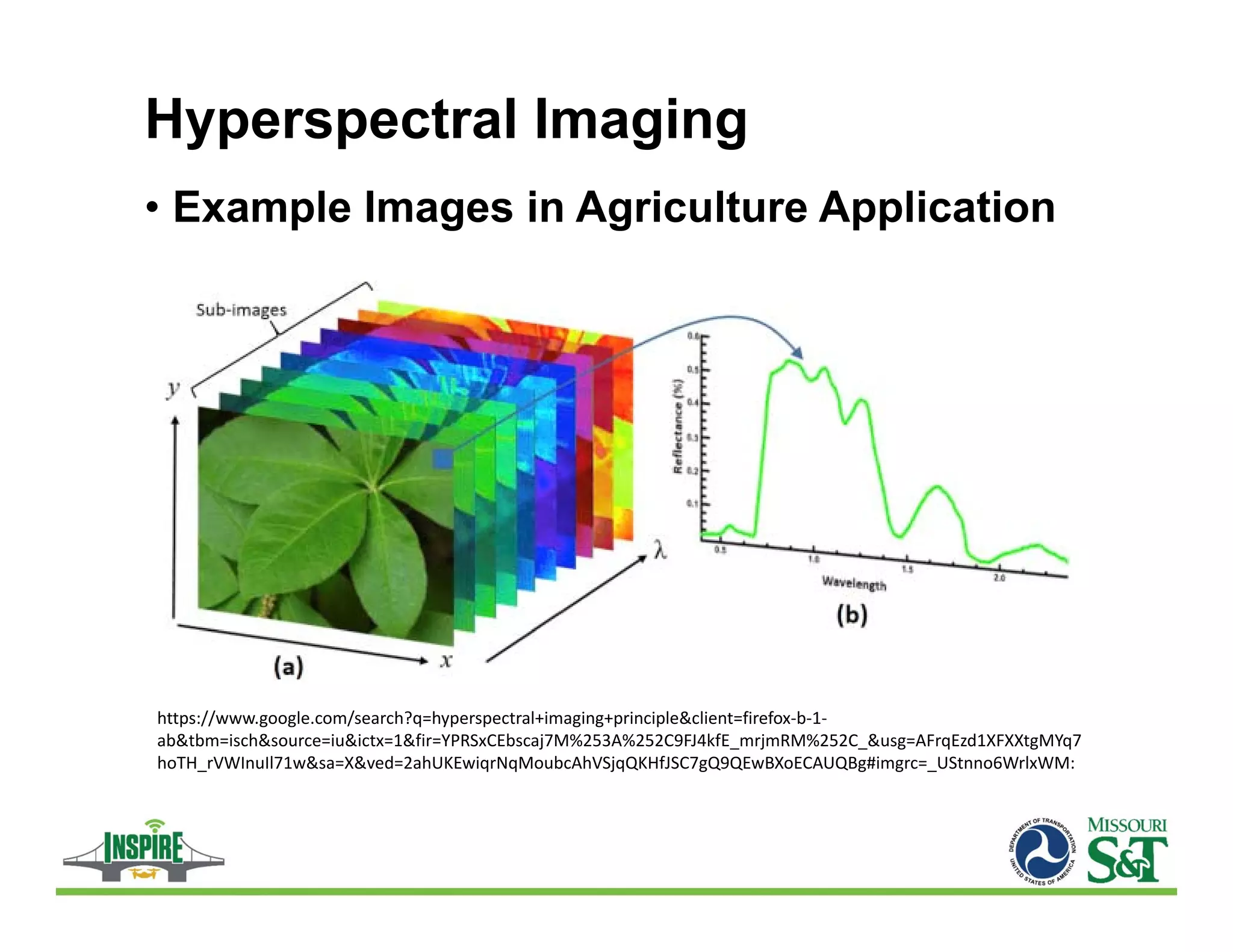

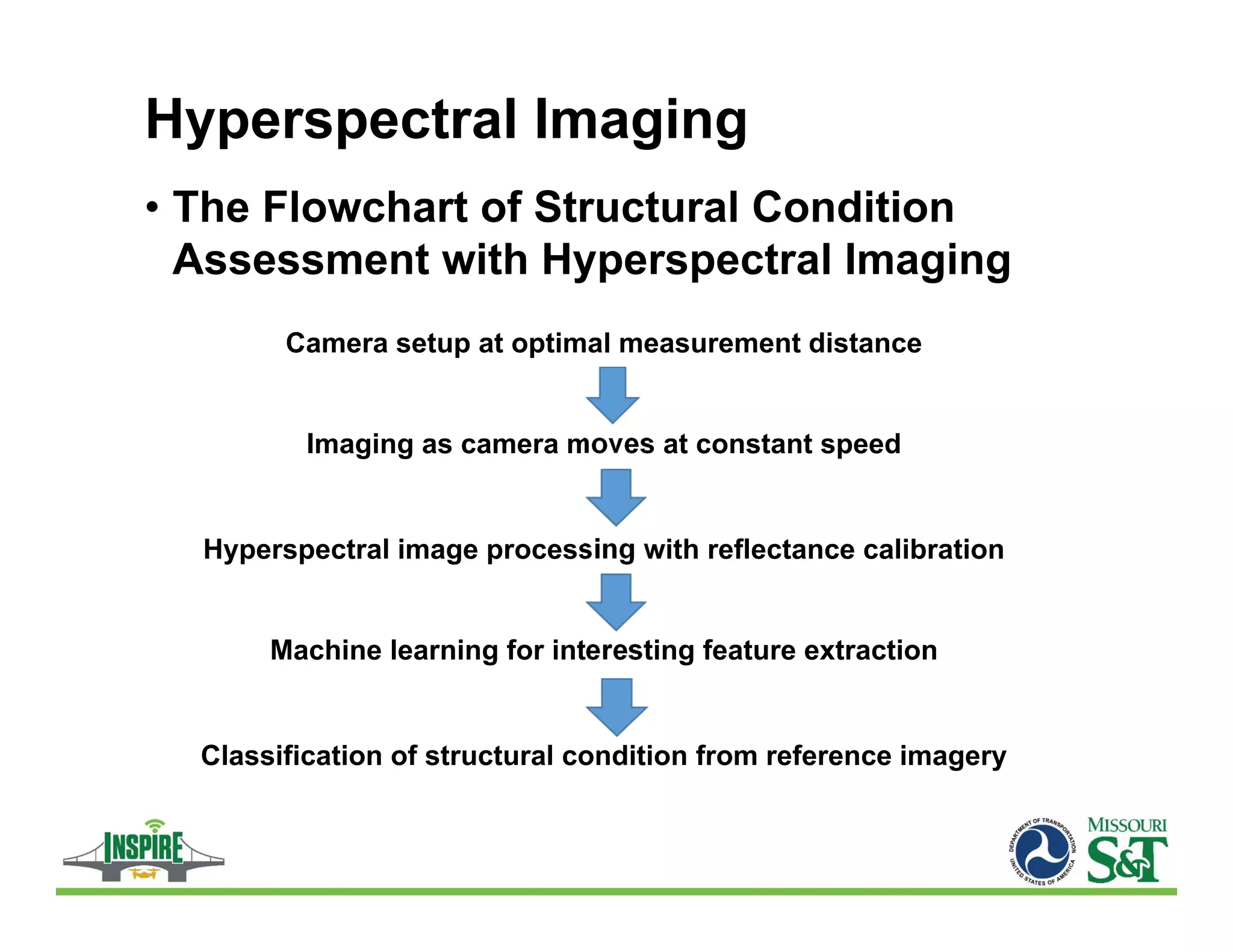

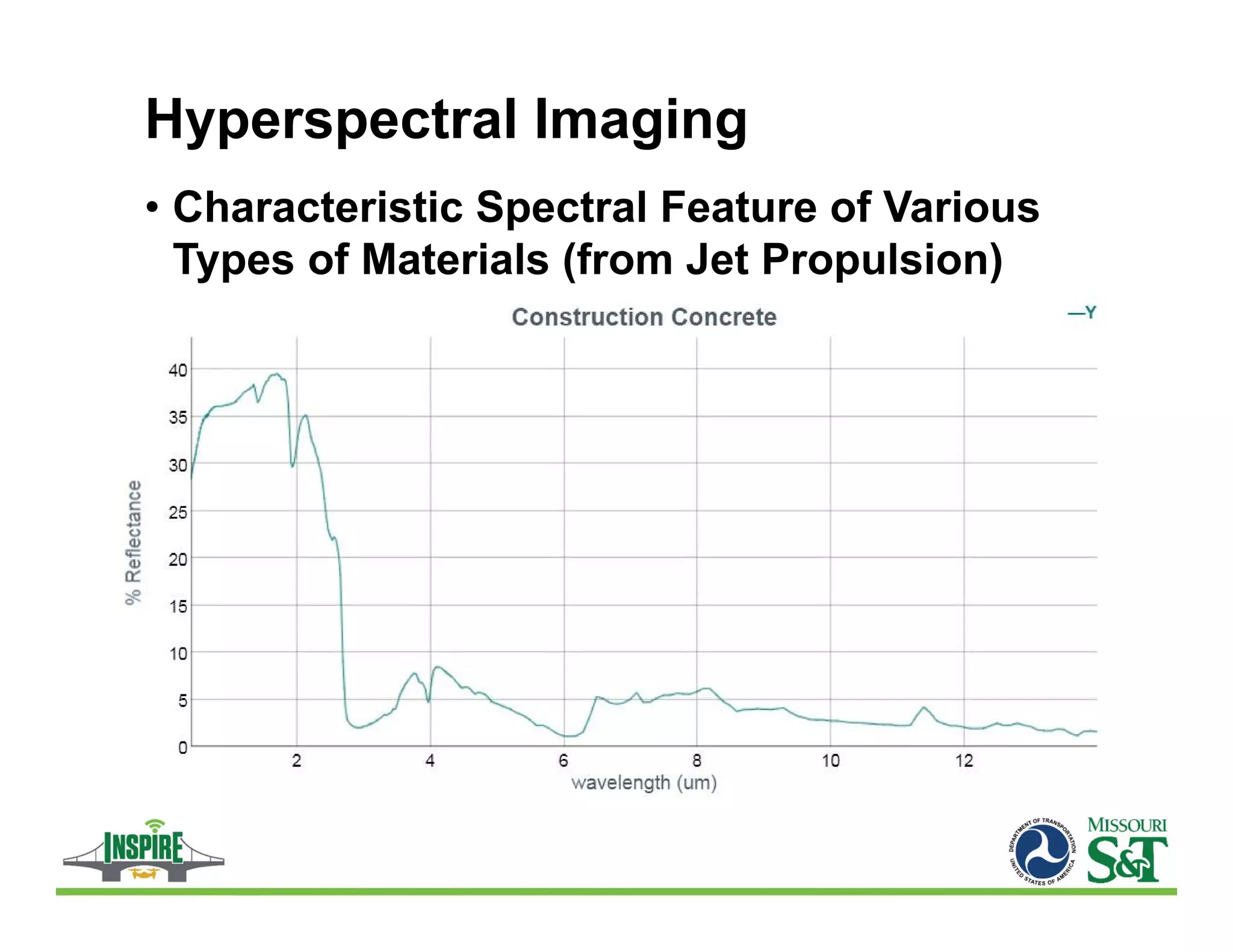

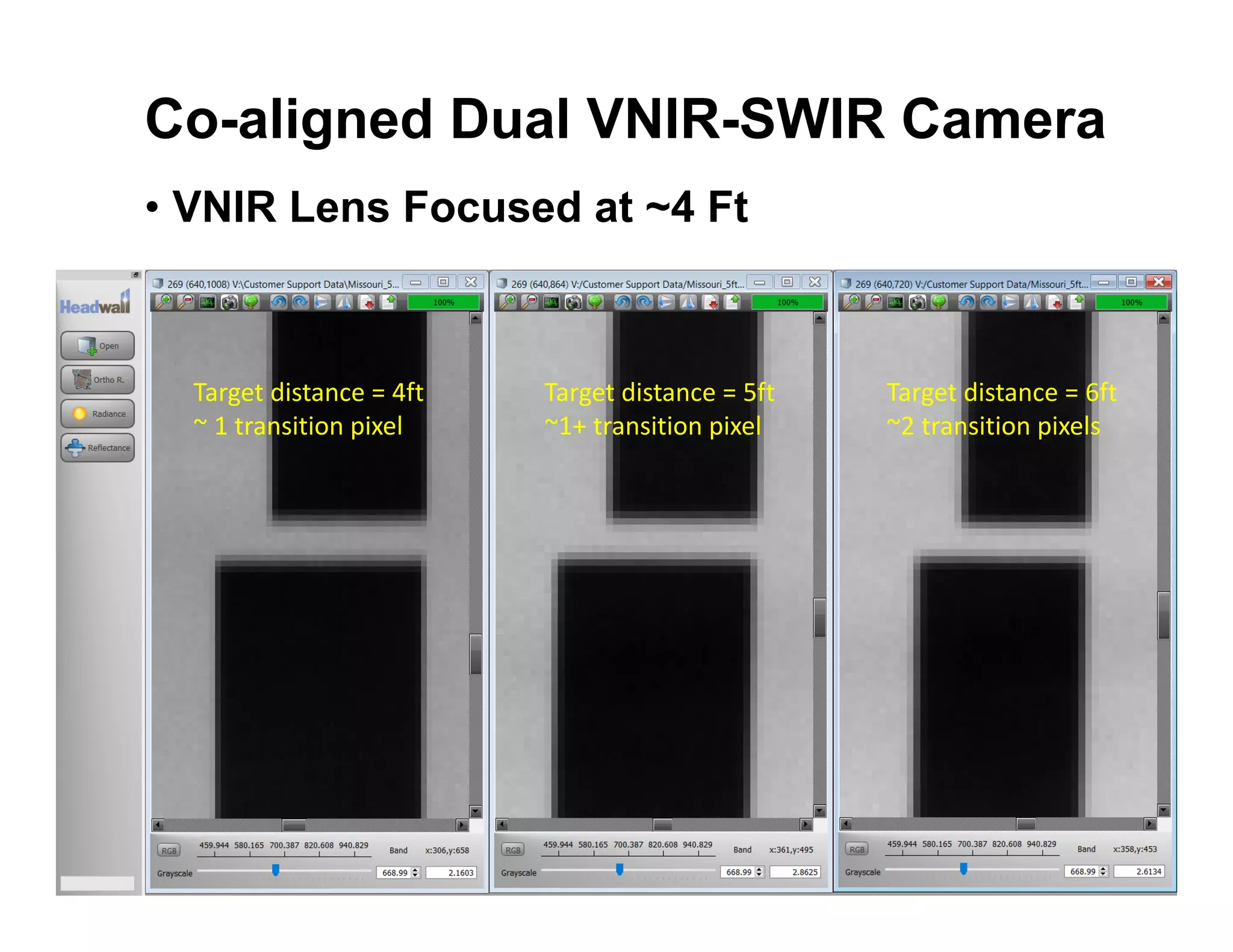

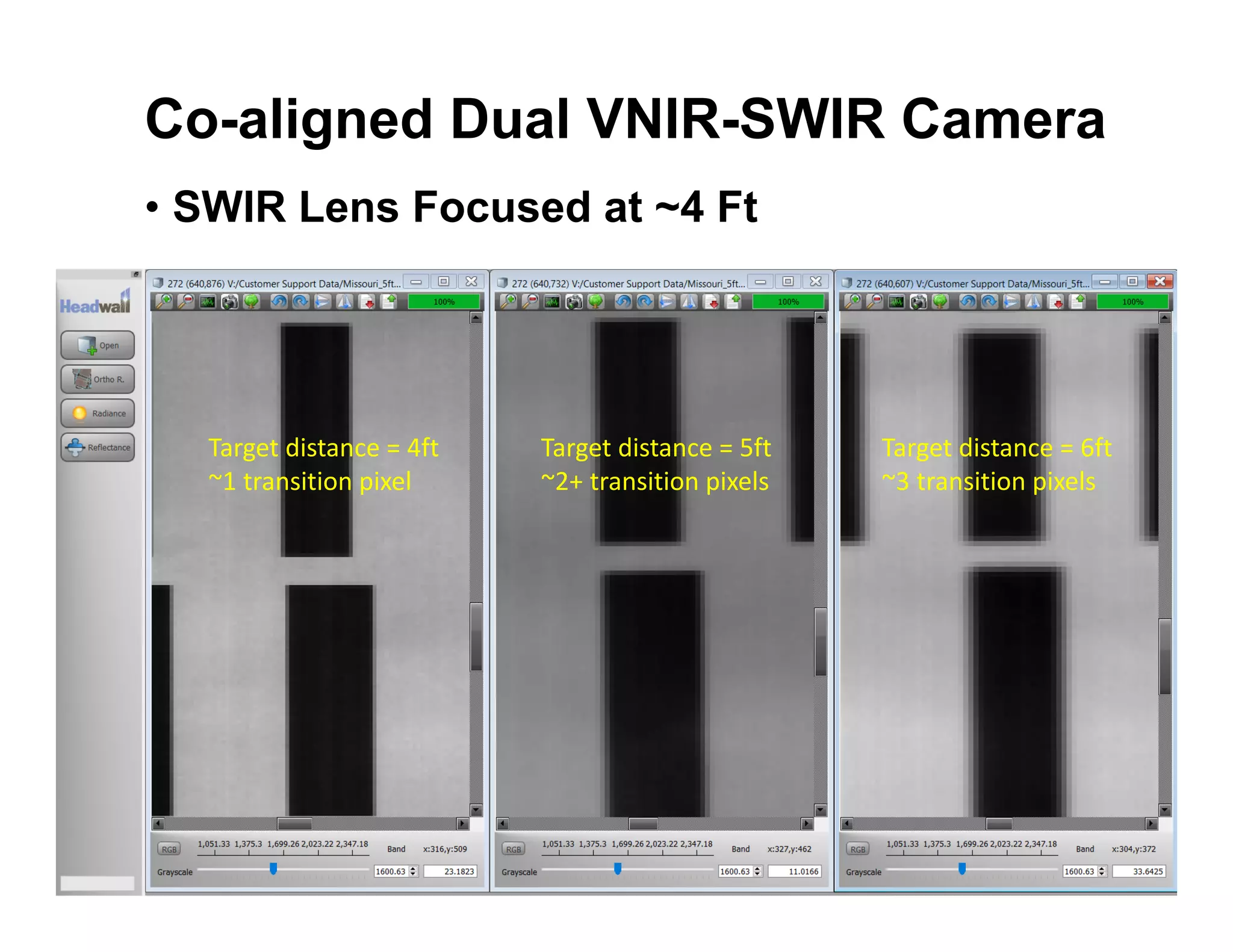

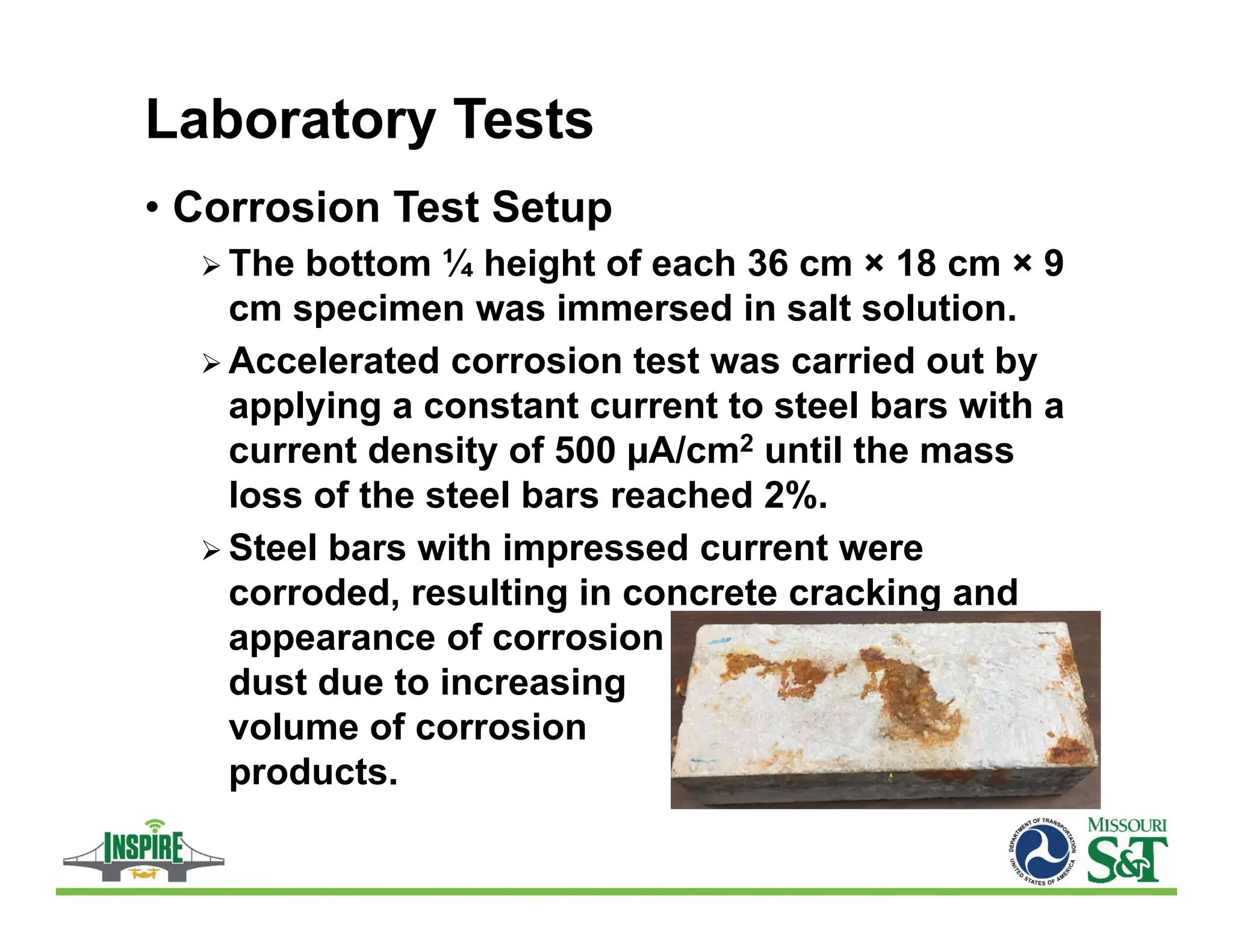

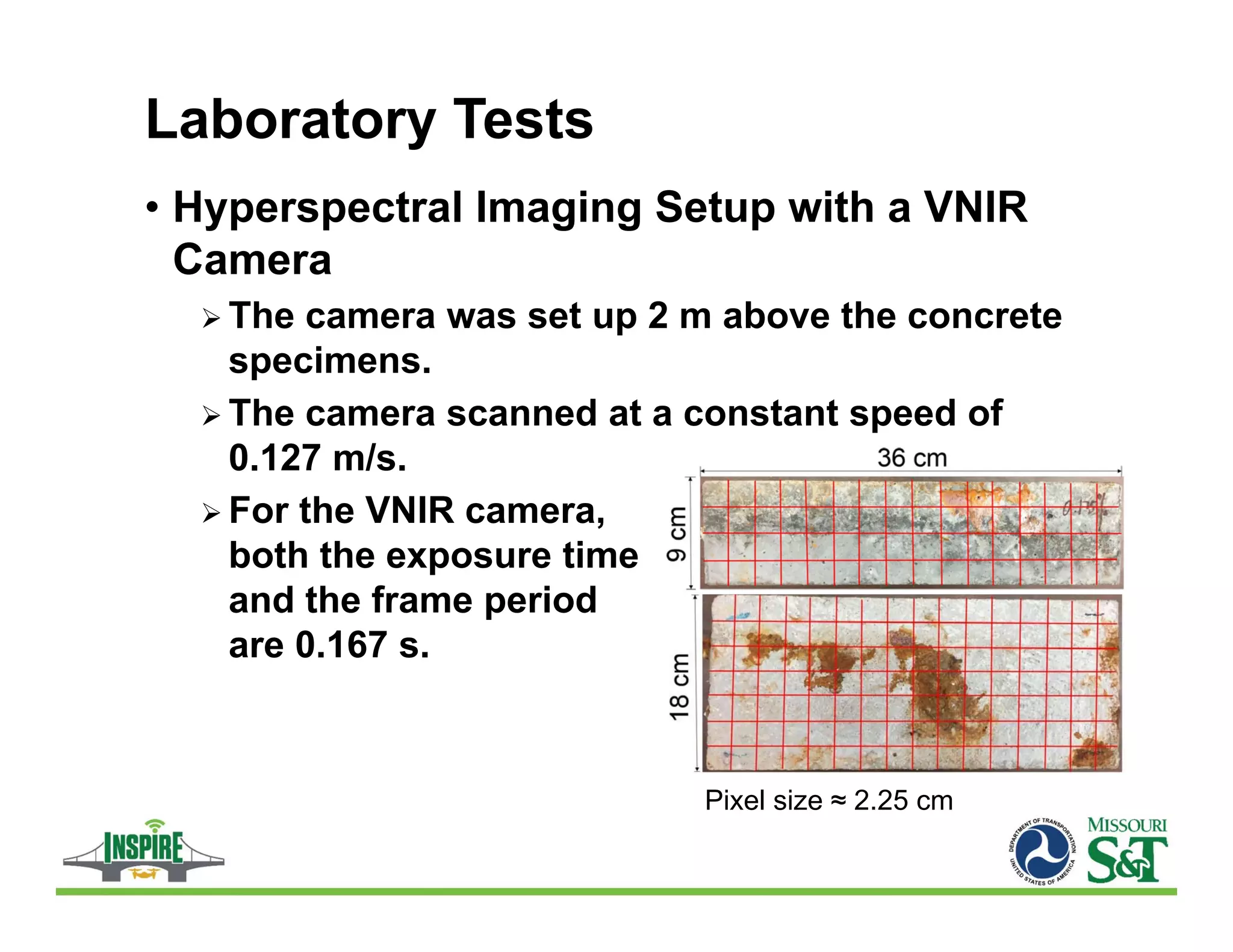

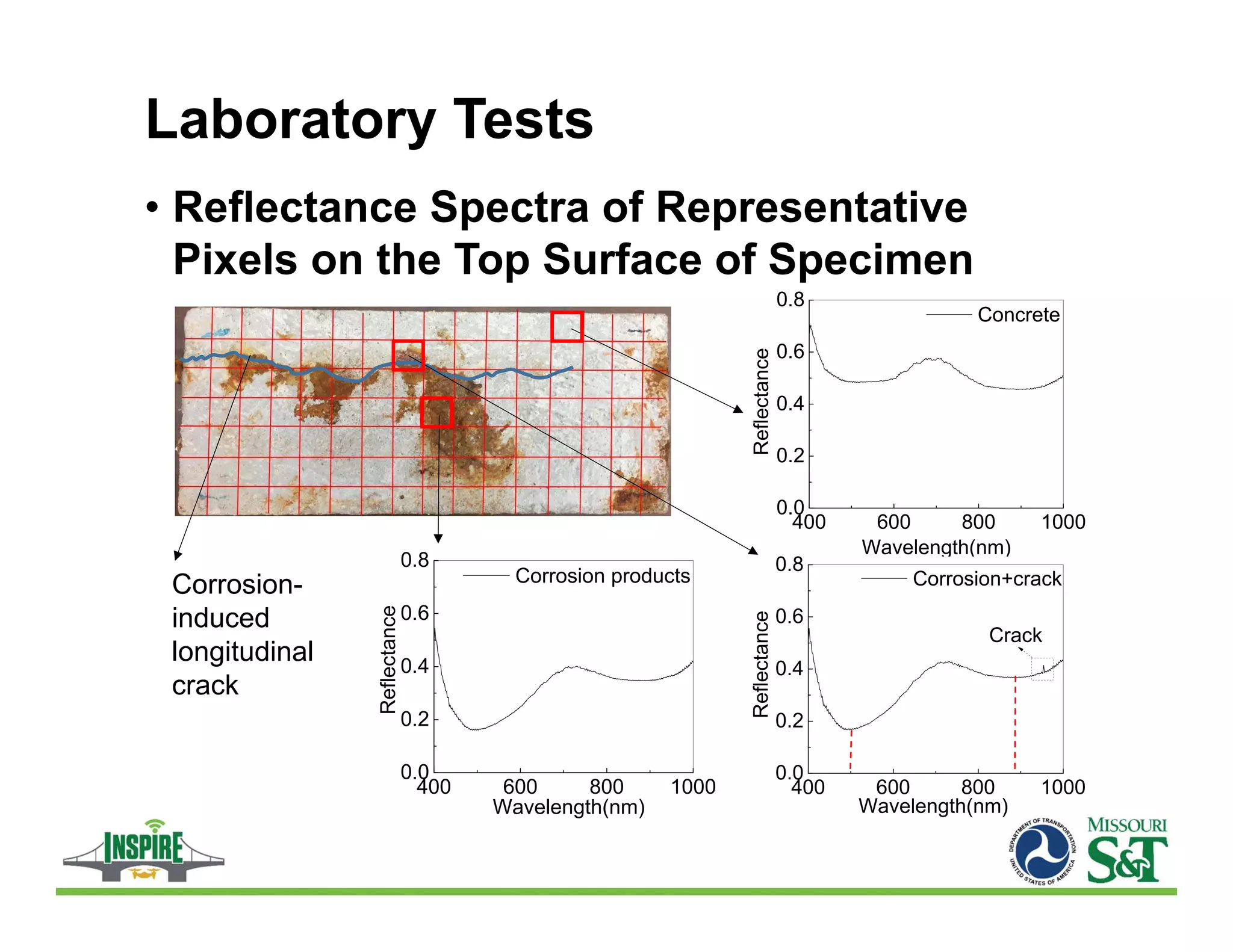

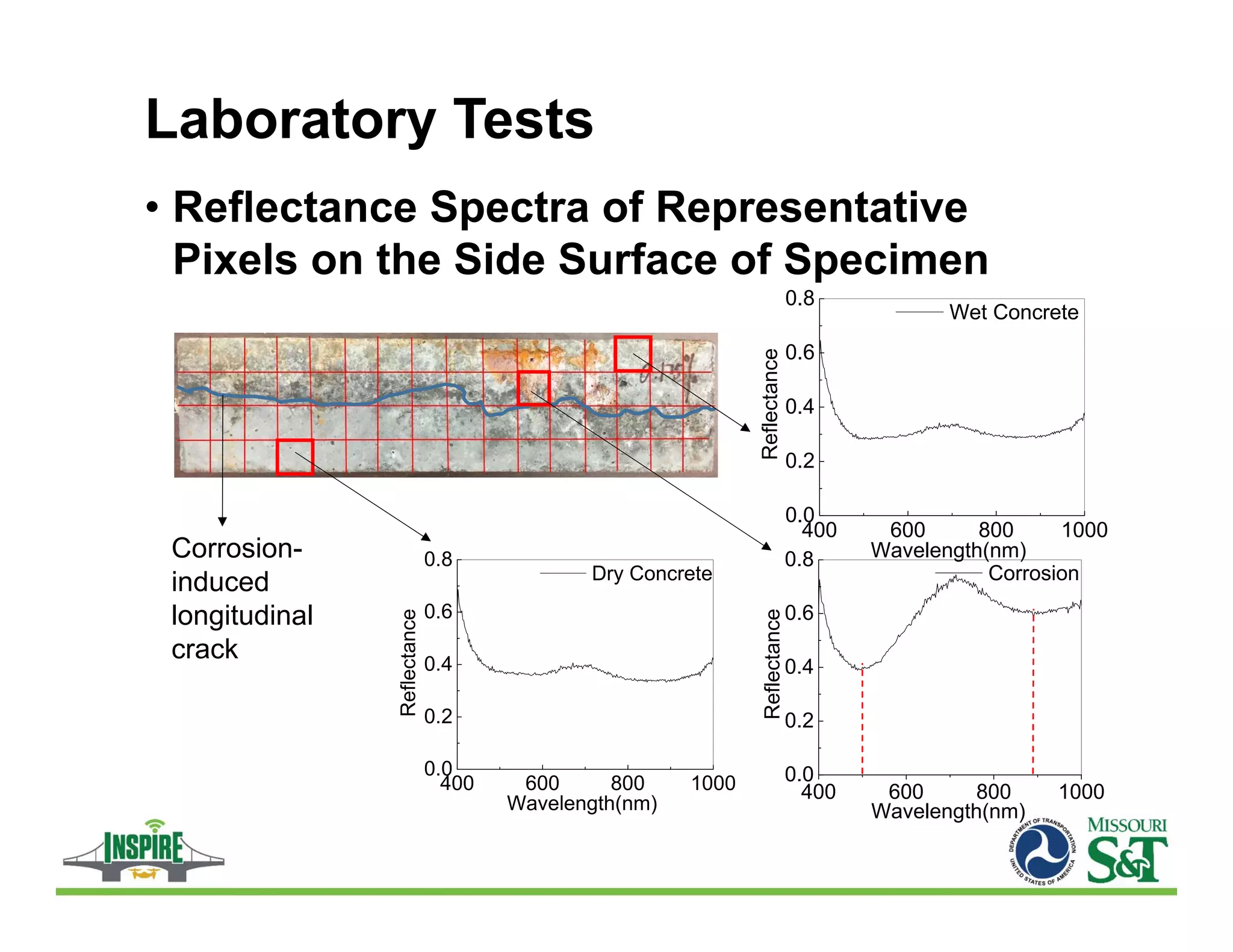

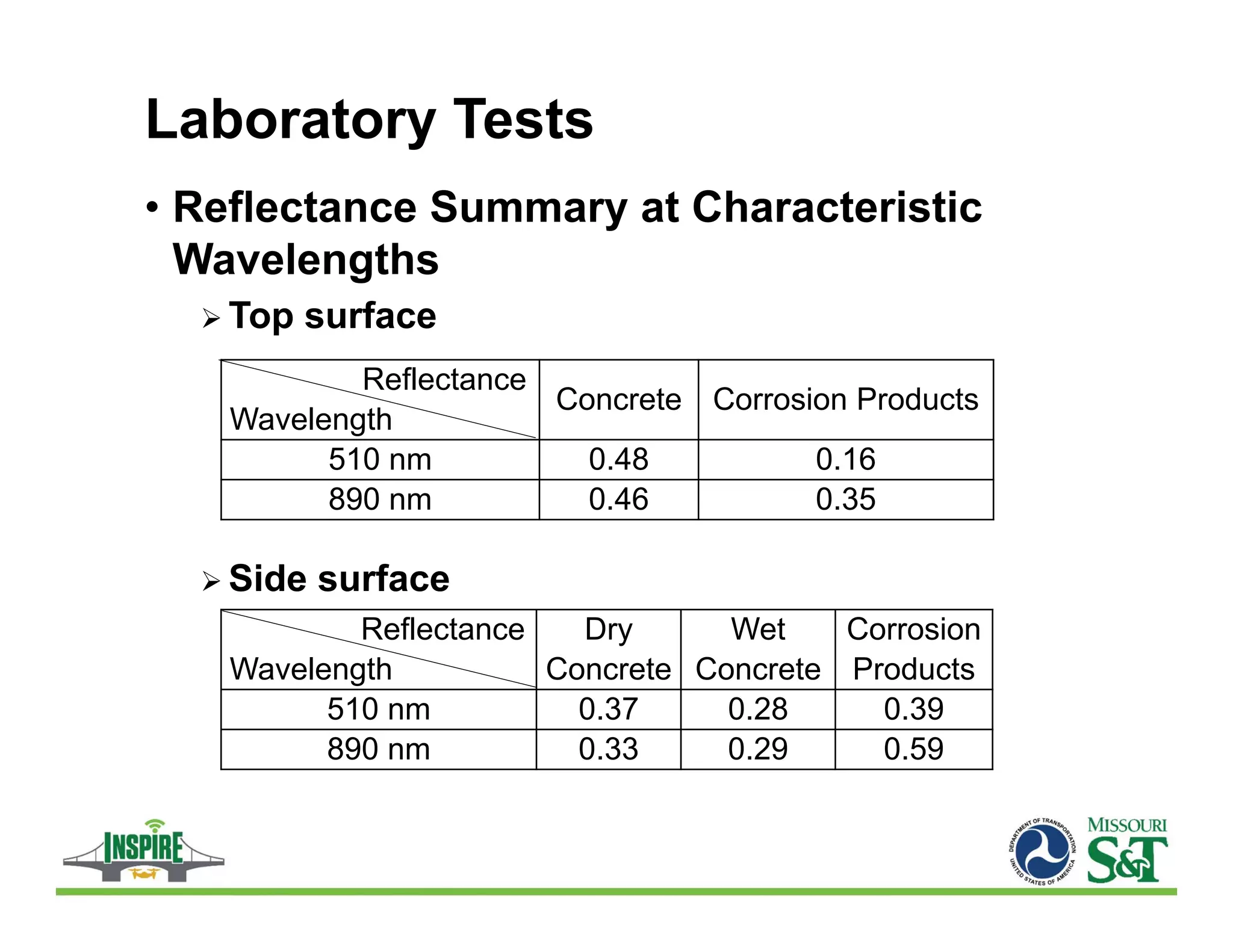

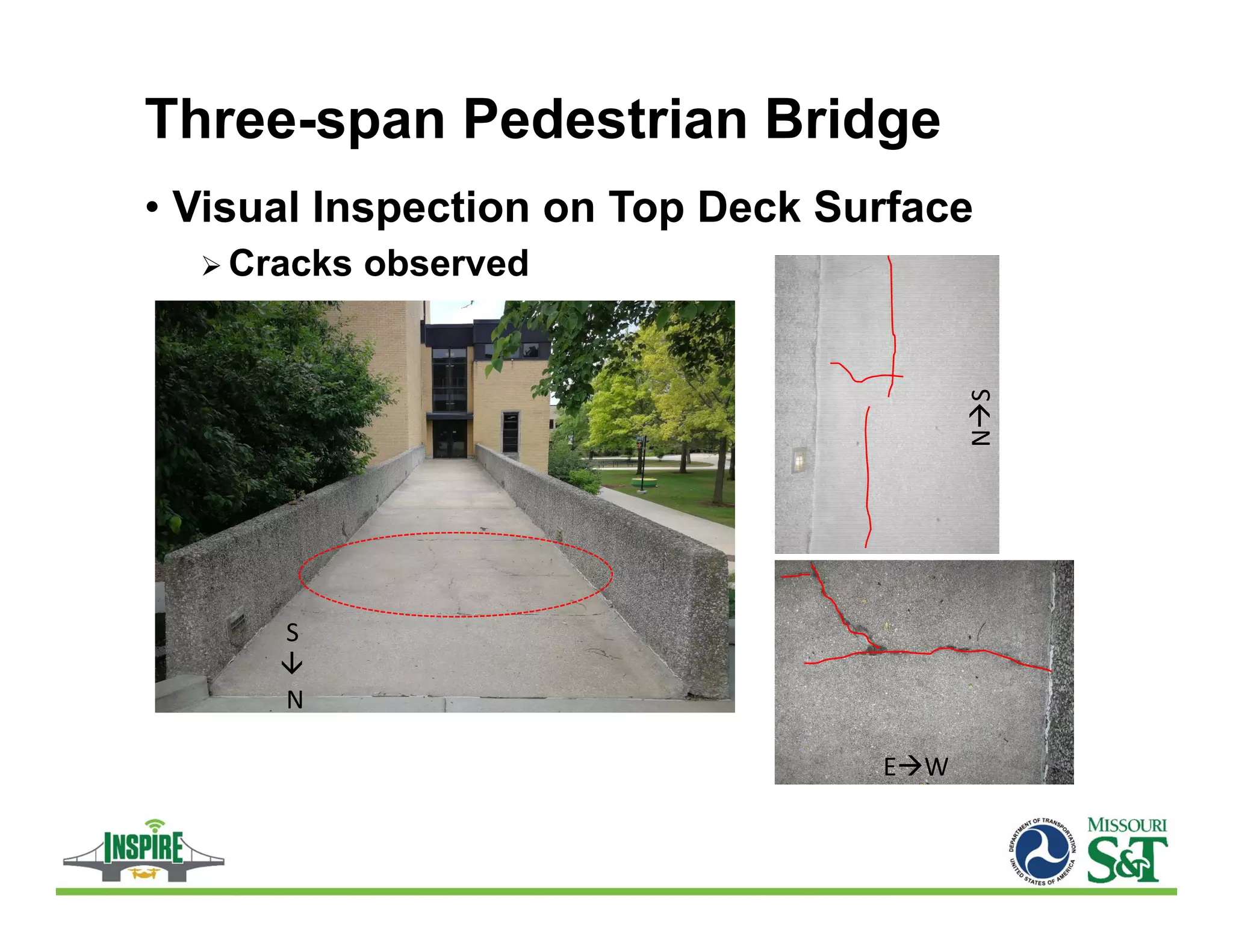

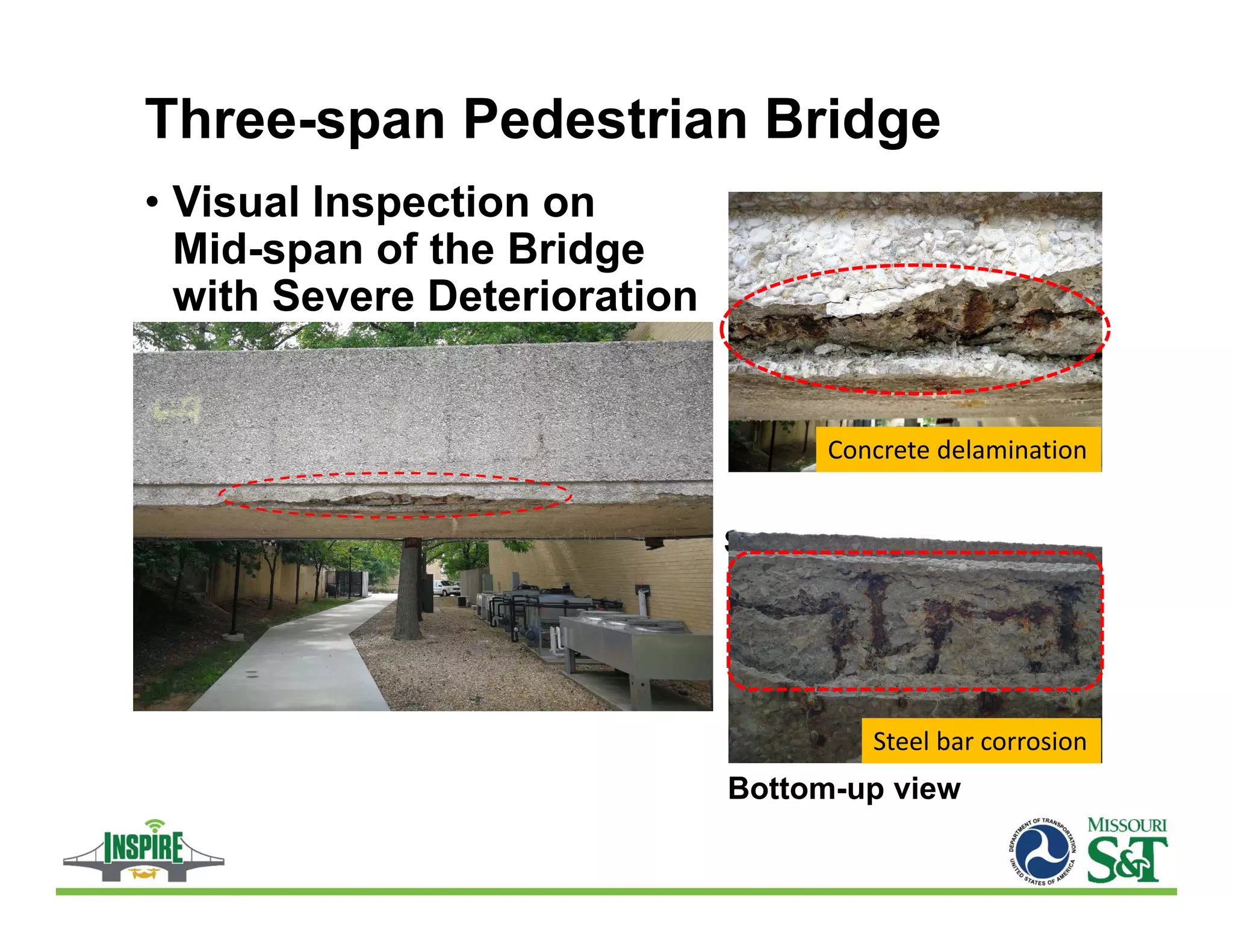

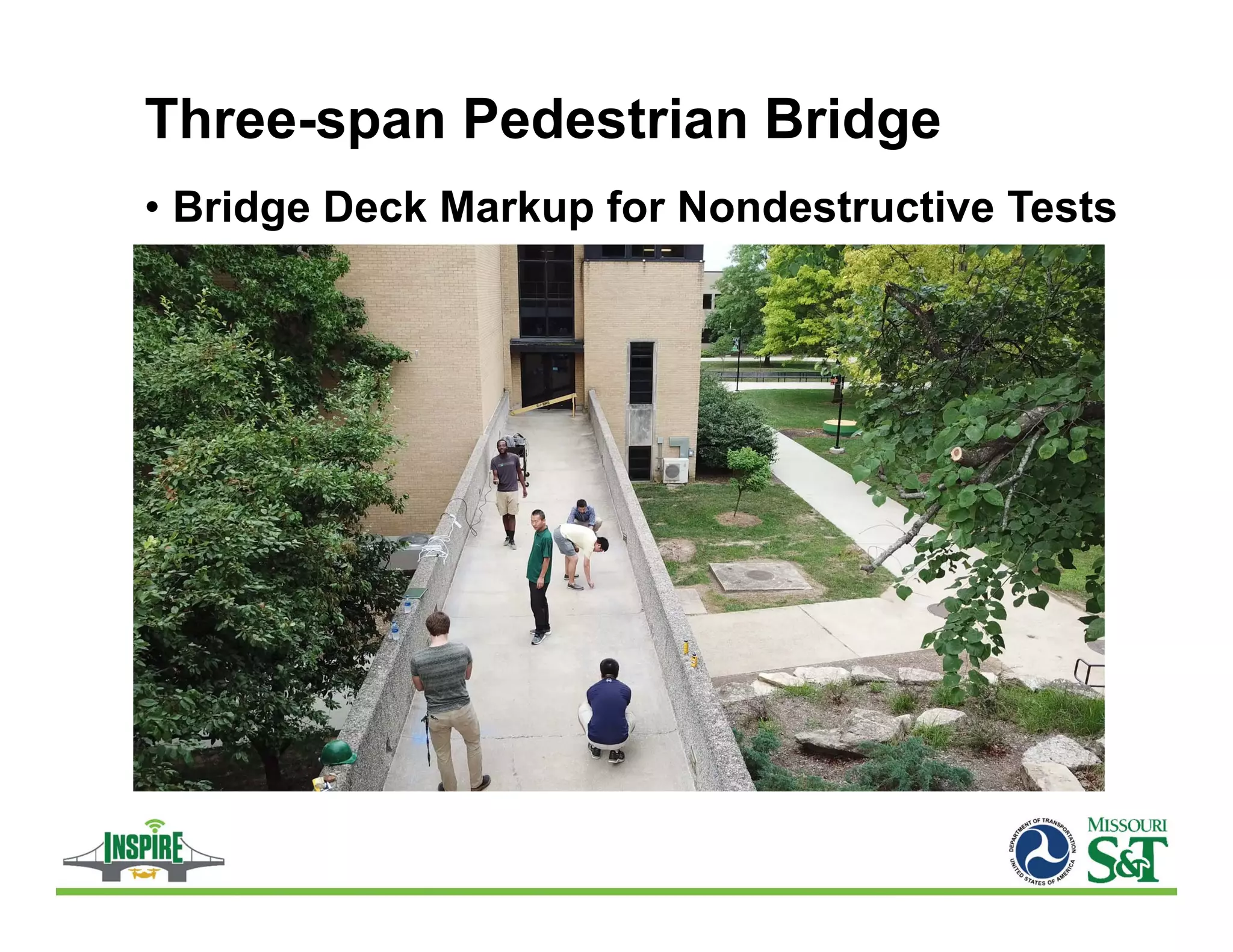

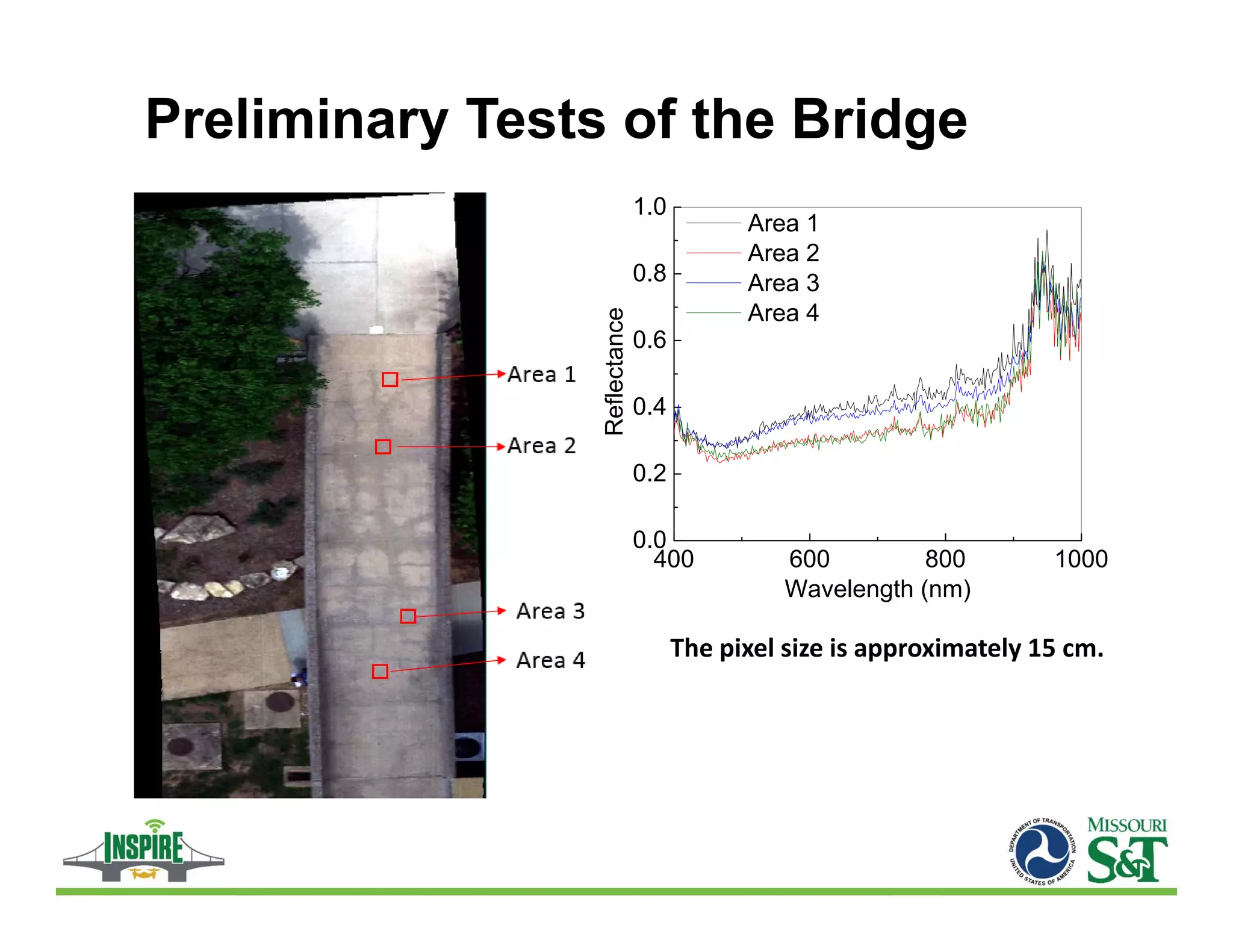

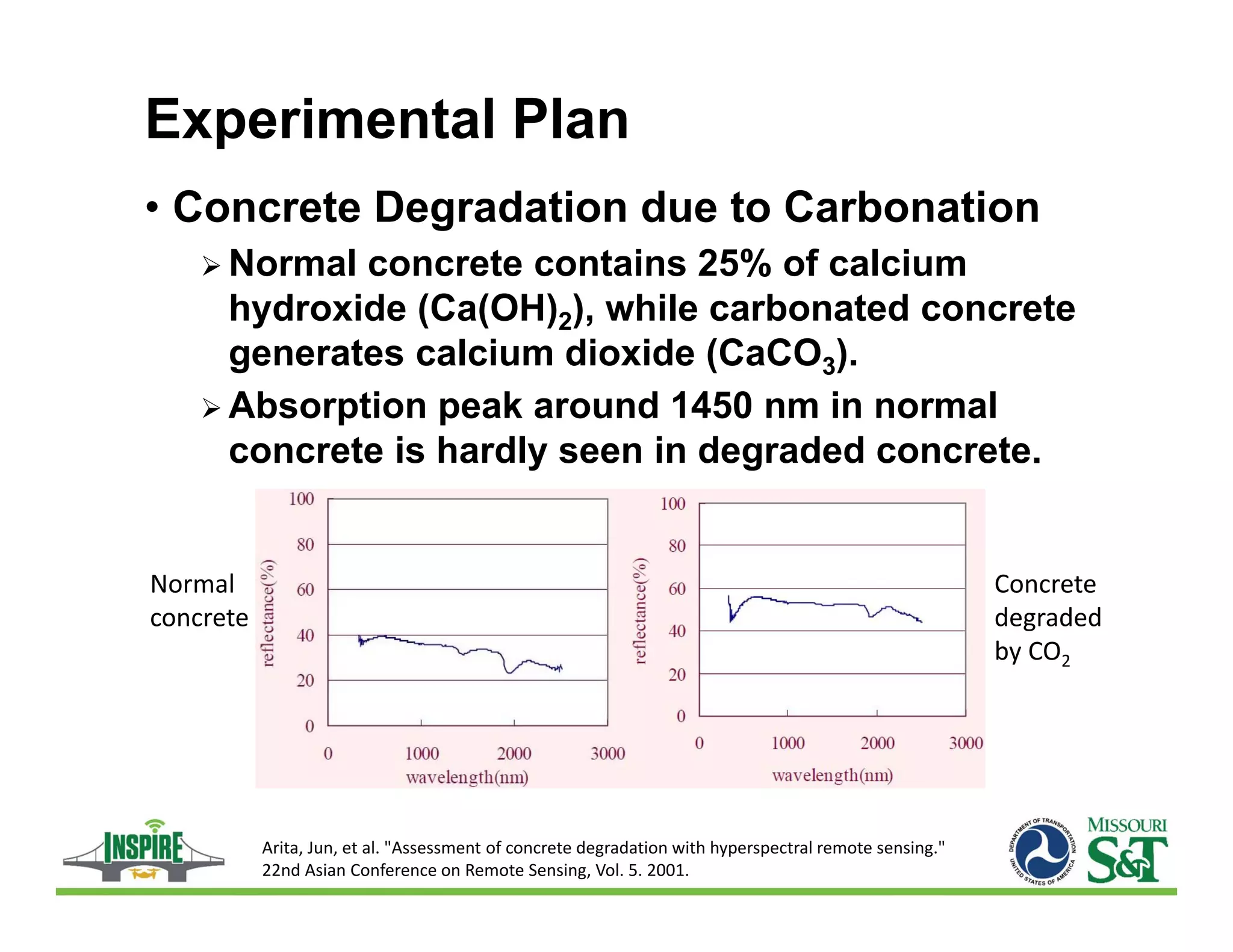

This document discusses using hyperspectral imaging to non-destructively inspect infrastructure like bridges. Hyperspectral cameras capture reflectance spectra across hundreds of narrow bands, allowing identification of physical defects and chemical properties unattainable through visual inspection alone. Preliminary tests on concrete specimens in the lab and on a 3-span bridge showed hyperspectral imaging could detect features like corrosion, cracks, and carbonation. Future work will study the effects of imaging parameters and develop classification models to predict degradation levels from the spectral data. The goal is to supplement traditional inspections with an objective, data-driven assessment tool.