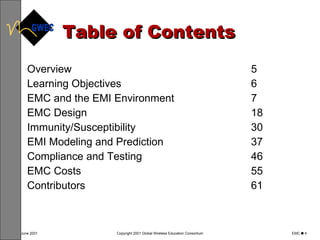

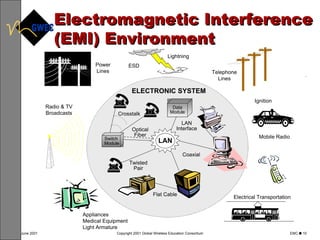

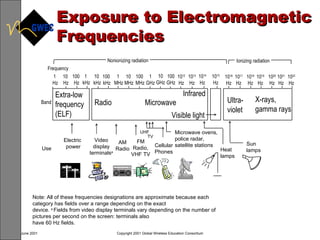

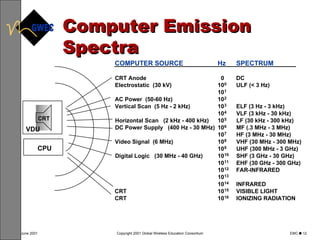

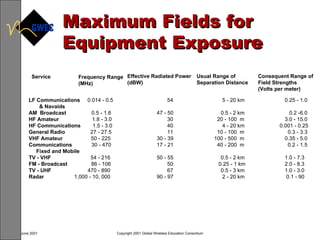

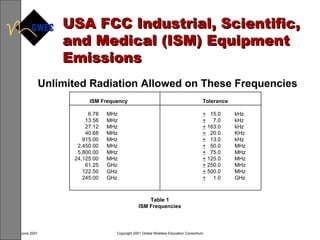

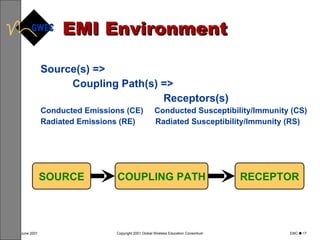

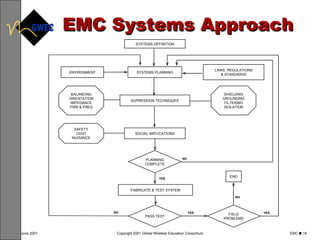

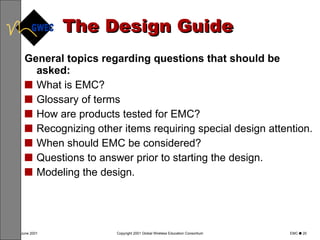

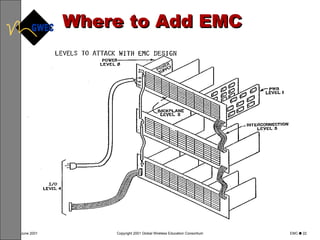

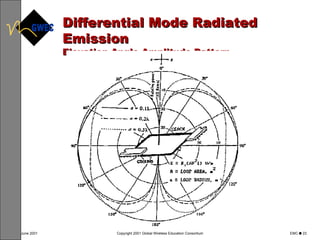

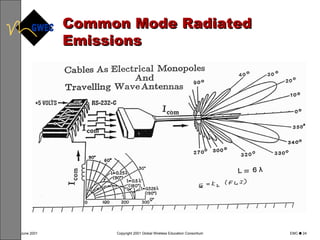

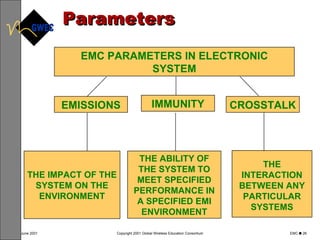

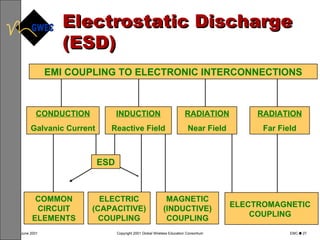

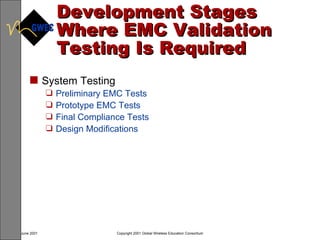

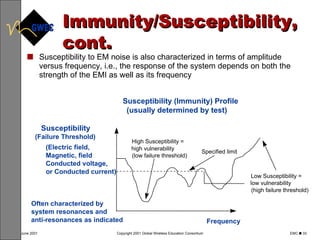

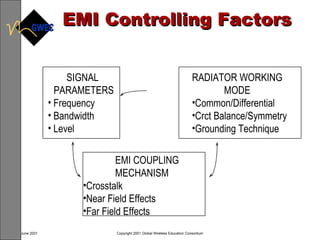

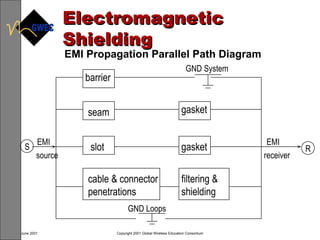

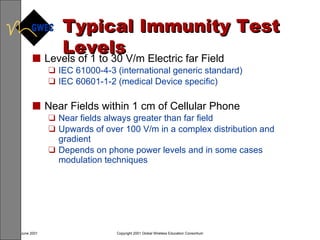

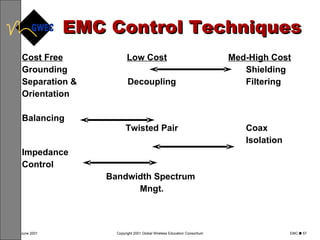

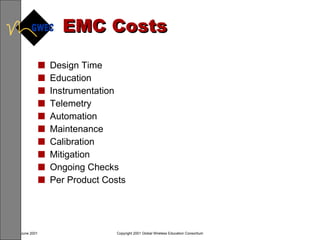

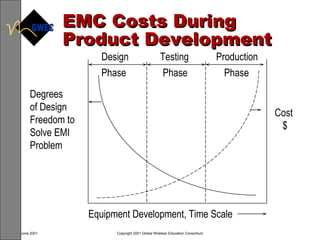

This document provides an introduction to electromagnetic compatibility (EMC). It discusses key topics related to EMC including the EMI environment, EMC design approaches, immunity and susceptibility, EMI modeling and prediction, compliance testing, and EMC costs. The goal of the module is to explain the fundamentals of EMC and how it can be addressed through various design, testing and compliance strategies.