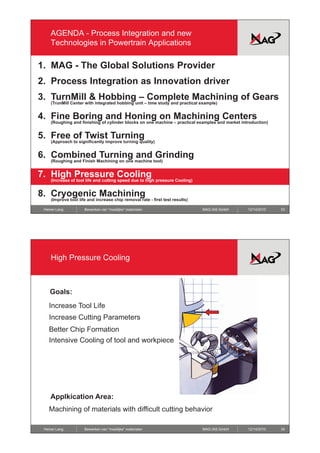

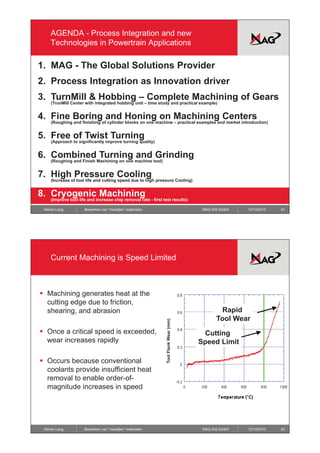

The document discusses new machining concepts and technologies for advanced metal cutting. It begins with an agenda that outlines topics such as MAG being a global solutions provider, process integration as an innovation driver, complete machining of gears using a TurnMill center with an integrated hobbing unit, fine boring and honing on machining centers, free of twist turning, combined turning and grinding, high pressure cooling, and cryogenic machining. The document then provides details on some of these topics, including concepts for milling, turning and gearing using modular machines, and examples of results from fine boring and honing processes.

![Application: Titanium Cutting

Turning of Titanium: Tool Life

Conventional Cooling

Material:

Ti6AlV4 High Pressure Cooling

Cutting Parameters:

Vc=60m/min

ap=2,5mm

f=0,25mm/rot

f=0 25mm/rot

Vc [m/min]

Conventional Cooling High Pressure Cooling

After 2 min After 4 min

Heiner Lang Bewerken van “moeilijke” materialen MAG IAS GmbH 12/14/2010 39

Customer Applications @ MAG

Industry Sector: Turbine Parts

8 CNC-Turning Machines for

Airplane Turbine Parts have

p

been delivered along with High

Pressure Cooling

Work Piece: Planet Carrier

Turning, Drilling, Milling on

MAG TurnMill Center

Heiner Lang Bewerken van “moeilijke” materialen MAG IAS GmbH 12/14/2010 40](https://image.slidesharecdn.com/langmag-110105080745-phpapp02/85/Hr-Lang-20-320.jpg)

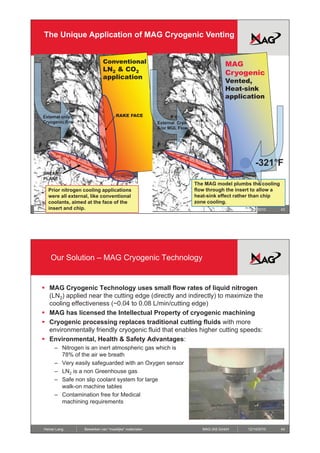

![Key Advantages – MAG Cryogenic Technology

ƒ Machining Performance

– 4X increase in processing speed for CGI

– 2-3X increase in processing speed for titanium

– 10X improvement in tool life for titanium 0.24 L/min of Liquid Nitrogen (ICS)

10

10X Improvement

min)

Tool Life (m

5X Improvement

1

15 L/min Flood Coolant

0.1

200 300 400 500

Surface Speed (ft/min)

40% Longer Cycle Time in

g y Dramatic Improvement in

Titanium for Flood Coolant Tool Life and Speed

Heiner Lang Bewerken van “moeilijke” materialen MAG IAS GmbH 12/14/2010 45

MAG Cryogenic Performance Data - Titanium

Workpiece Material Operation Speed Results

300 SFPM (91 M/min.) 300 SFPM: 6 min. of in cut time (3 for flood) (2X)

Titanium Plunge Milling

400 SFPM (122 M/min.) 400 SFPM: 2 min. of in cut time (1 for flood) (2X)

Tool:

T l KMT 2 inch Pl

i h Plunge Mill with 5 Fl t

ith Flutes

Insert: SDCT120432ENLD2-KC725

Width of Cut: 0.875 inches

Plunge Depth: 1 inch Liquid Nitrogen

Stepover: 0.350 inches

CLPT: 0.00314 in/tooth

10

0.76 L/min of Liquid Nitrogen (ICS)

Tool Life (min)

2X Improvement

p Flood Coolant

L

35 L/min Flood Coolant 2X Improvement

1

200 300 400 500

00

[91 M/min] [122 M/min]

Surface Speed (ft/min)

Cryo Modified KMT 2 inch Plunge Mill

Heiner Lang Bewerken van “moeilijke” materialen MAG IAS GmbH 12/14/2010 46](https://image.slidesharecdn.com/langmag-110105080745-phpapp02/85/Hr-Lang-23-320.jpg)