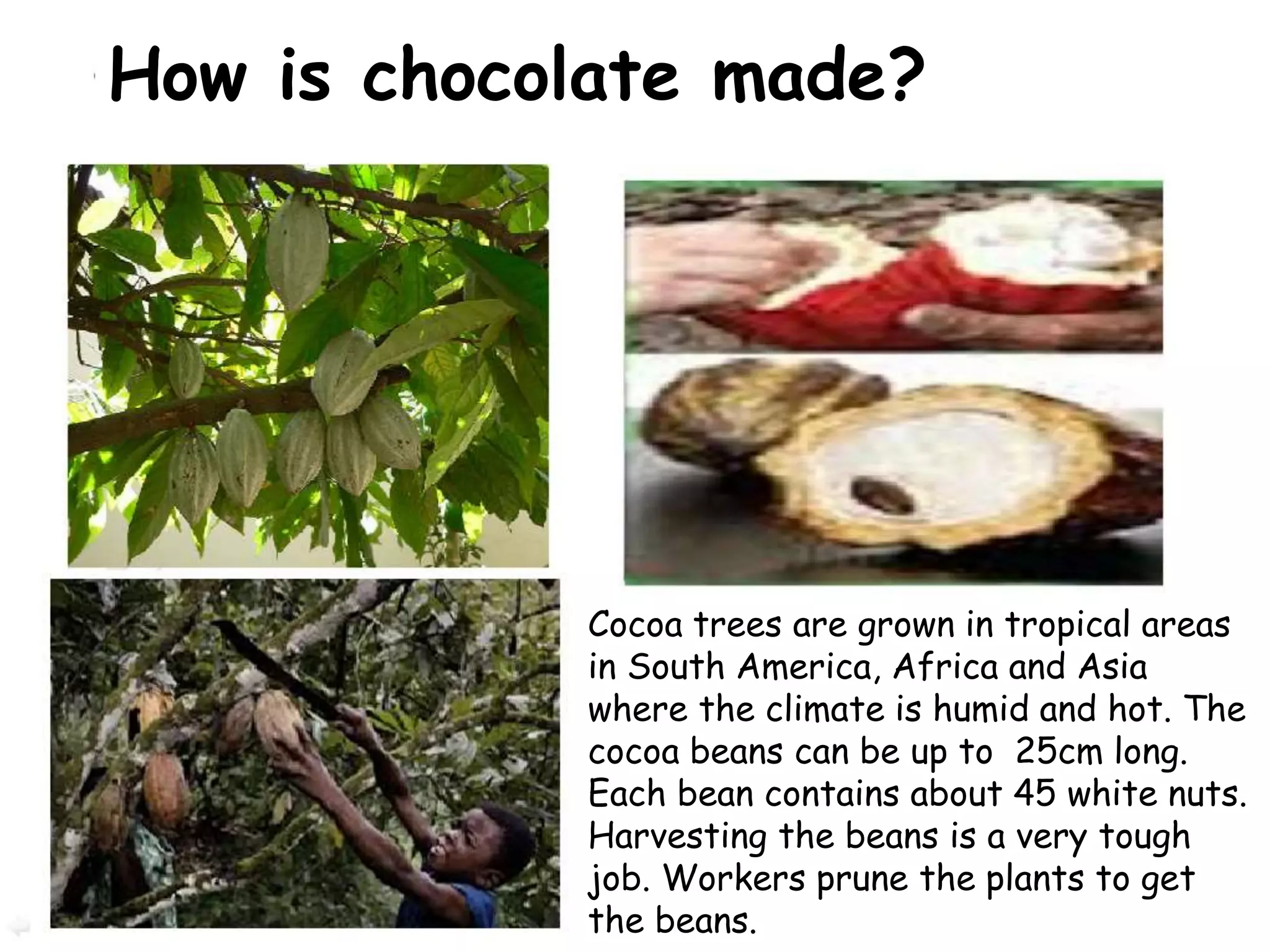

Chocolate is made from cocoa beans harvested from cocoa trees in tropical regions. After harvesting and fermentation, the beans are processed in factories where they are cleaned, roasted, and ground into chocolate paste. This paste is then mixed with milk and formed into various shapes before being packaged for retail.