This document provides details on the Hitachi Elevator VFI-II model, including:

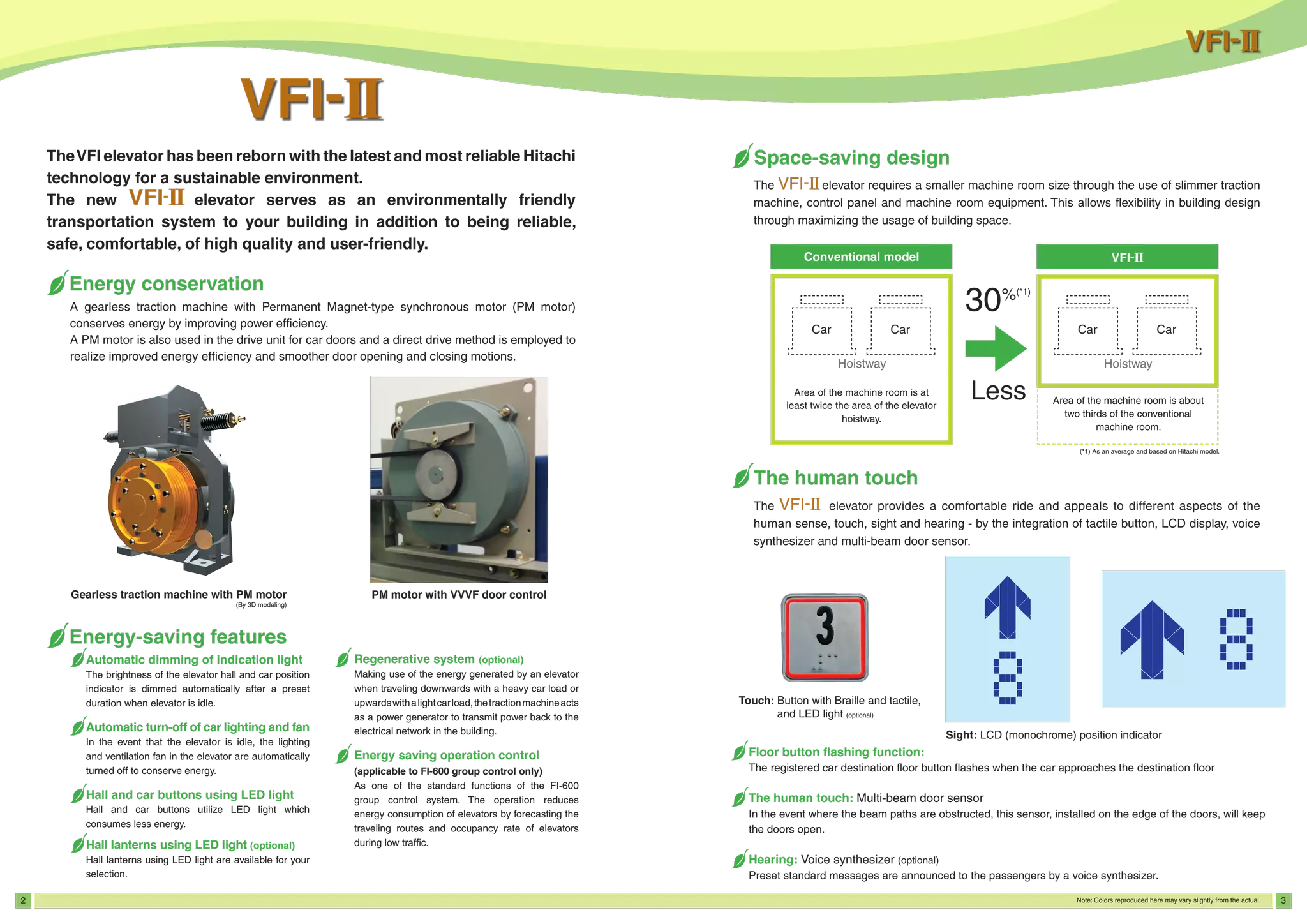

1. It describes several energy saving features such as automatic dimming of lights, turning off lights and fans when idle, and use of LED lights.

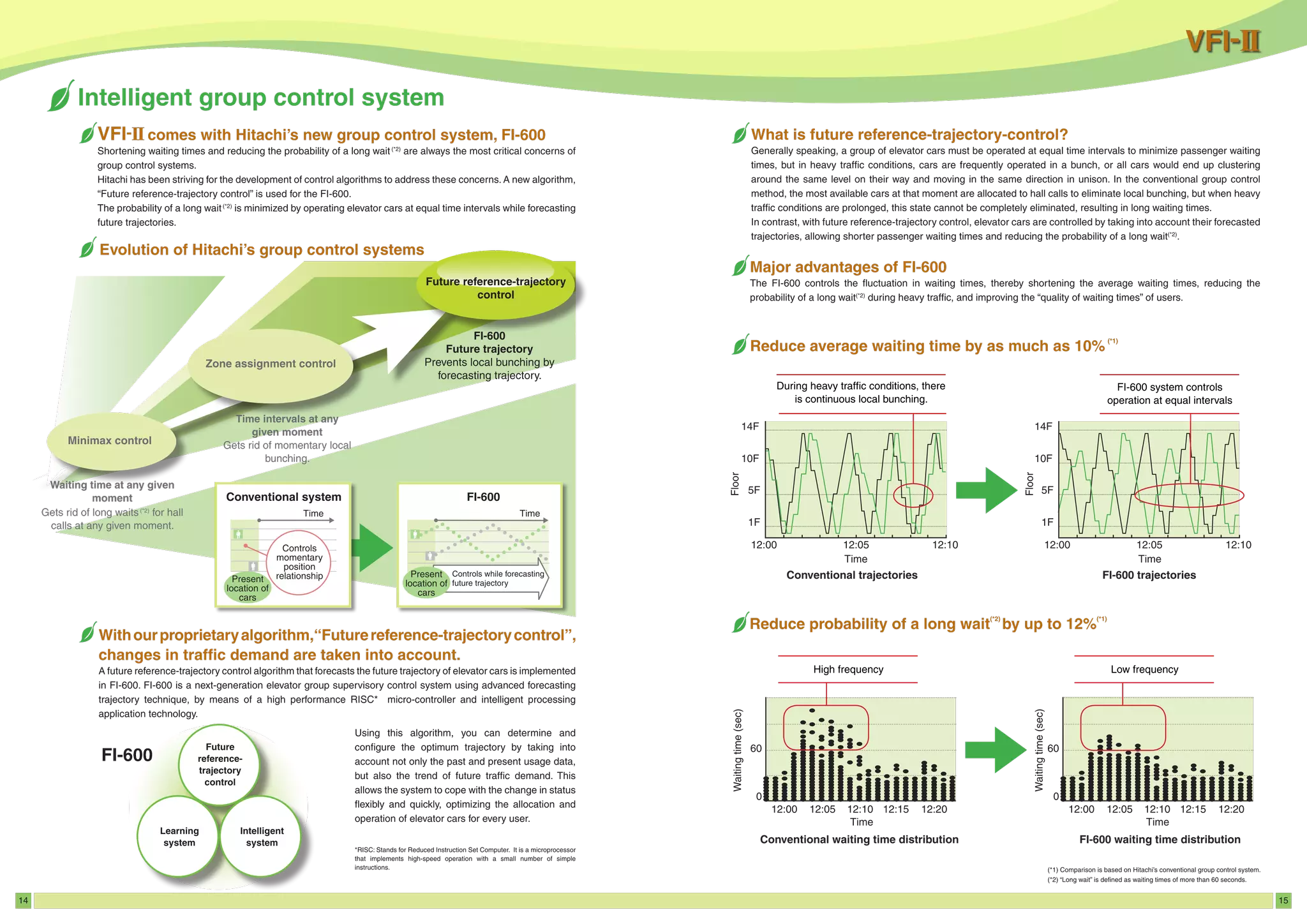

2. It lists optional features like a regenerative system and energy saving operation control for the FI-600 group control.

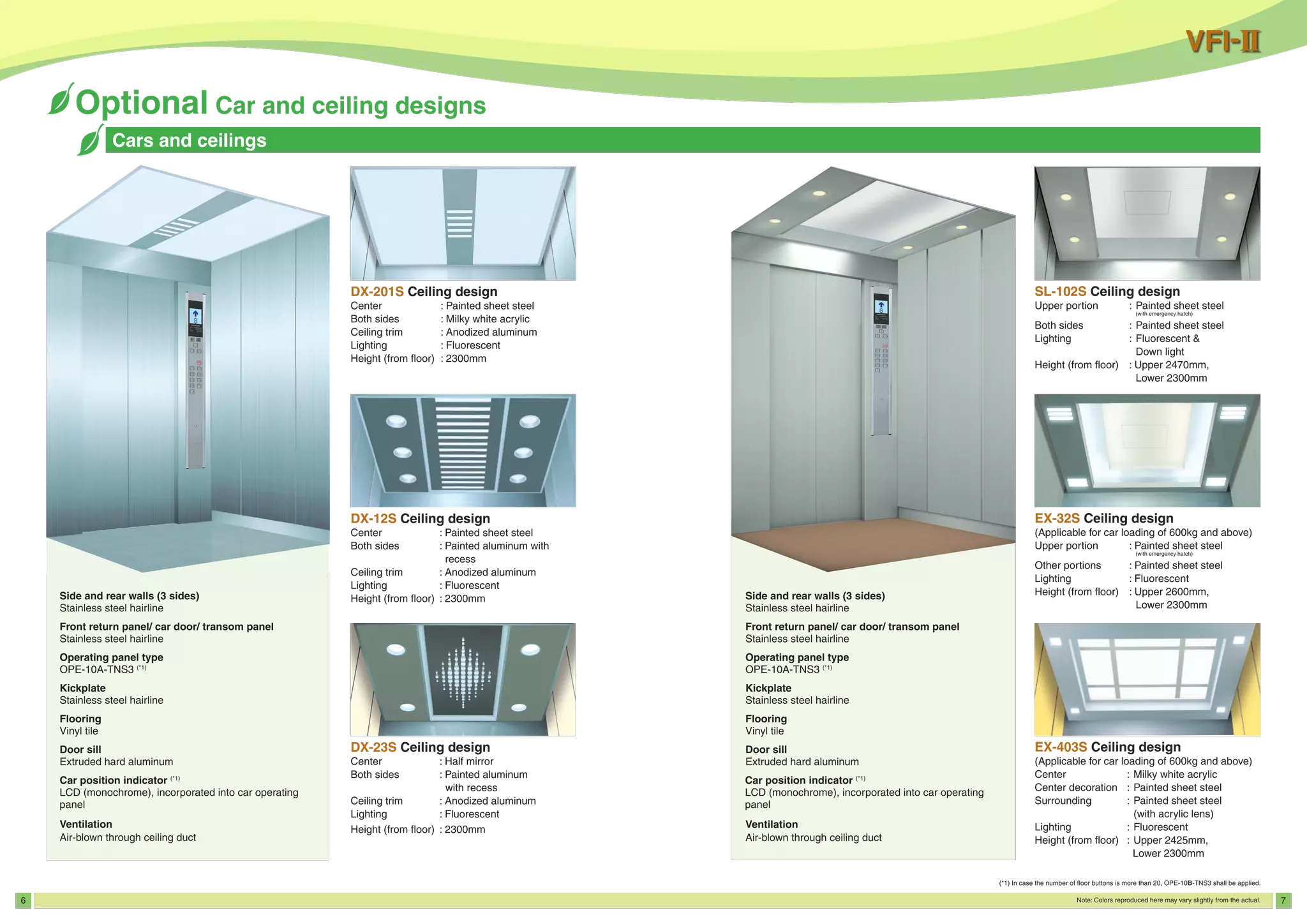

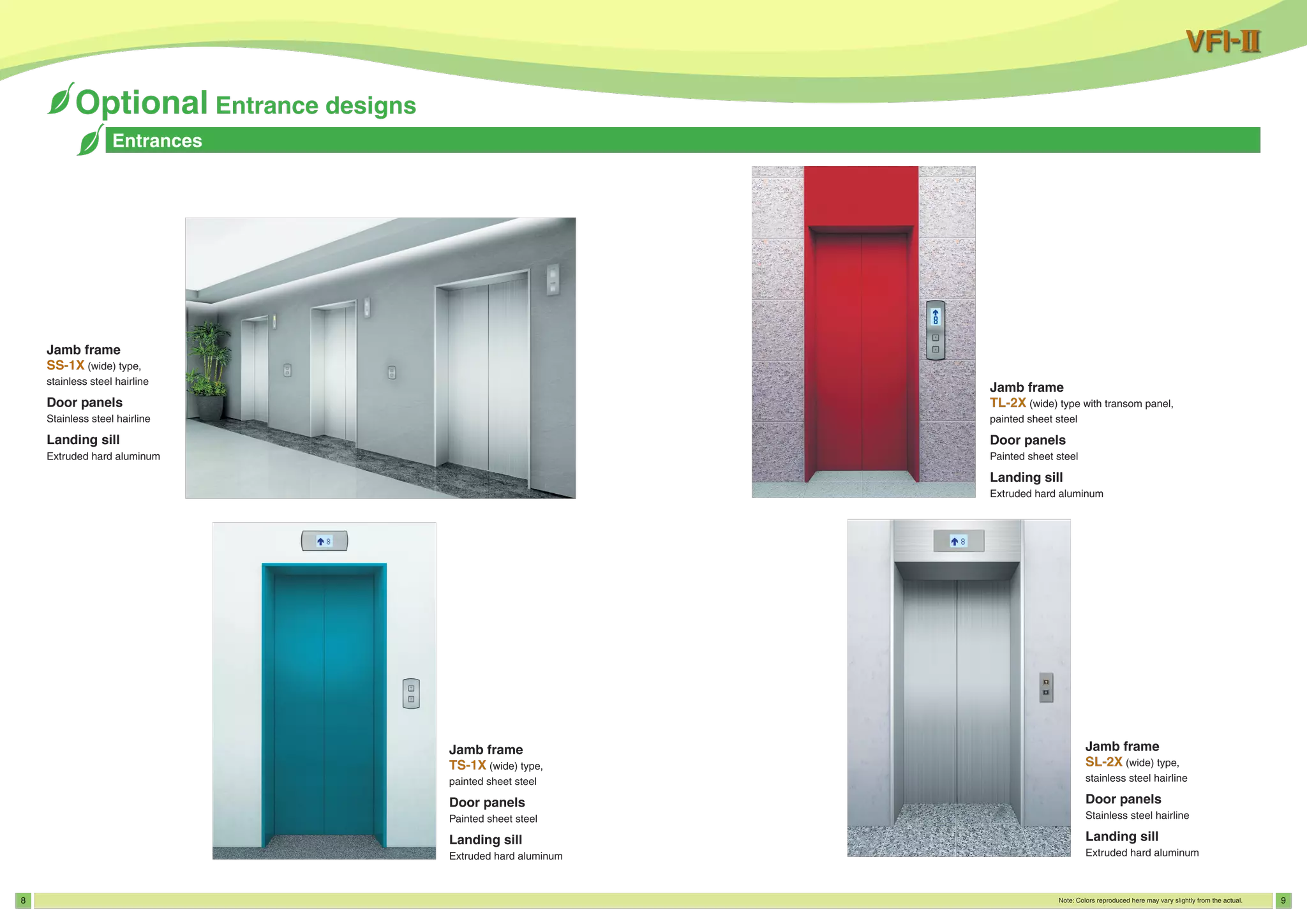

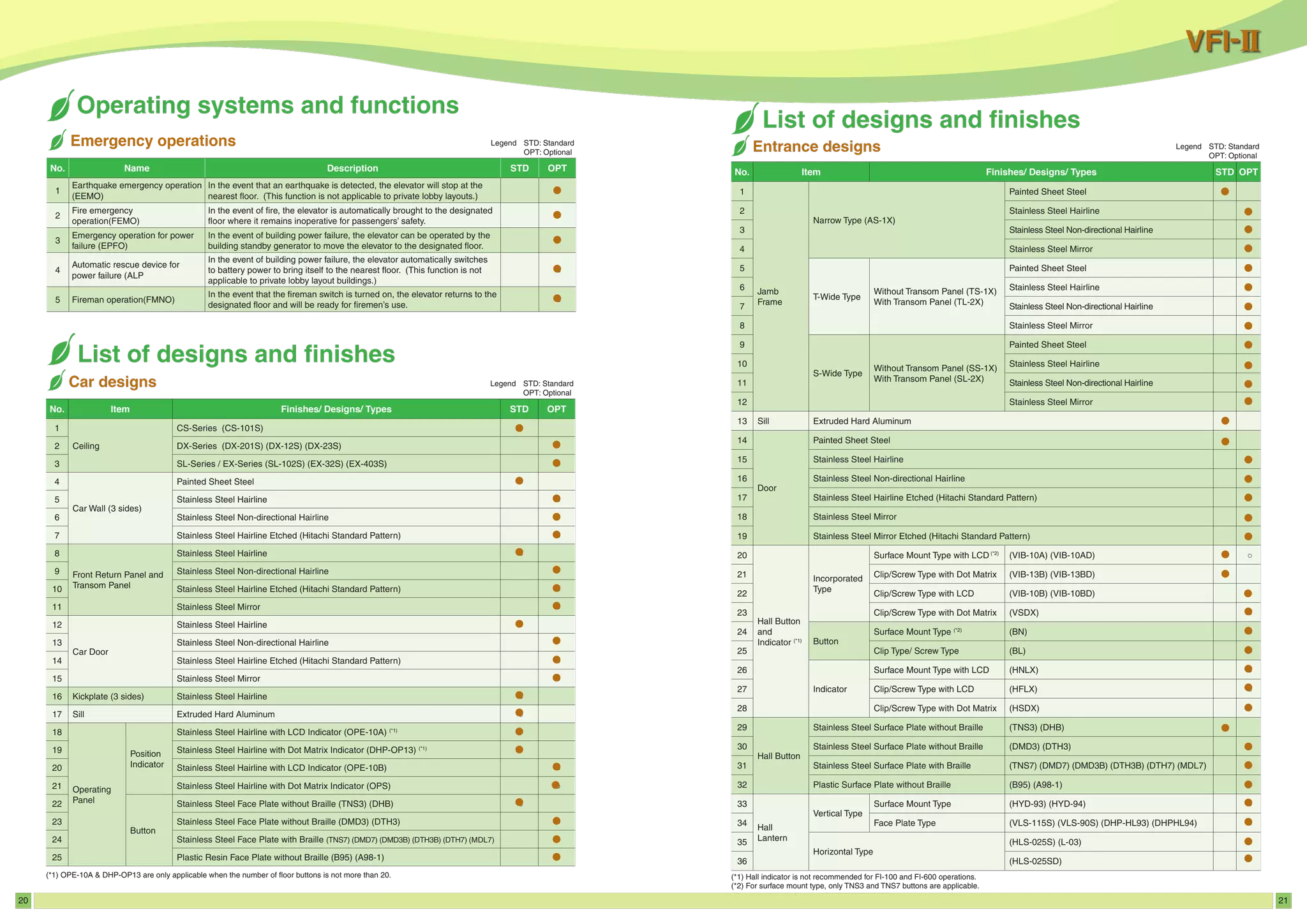

3. It provides an overview of components like cars and ceilings, operating panels, hall buttons, and hall lanterns.