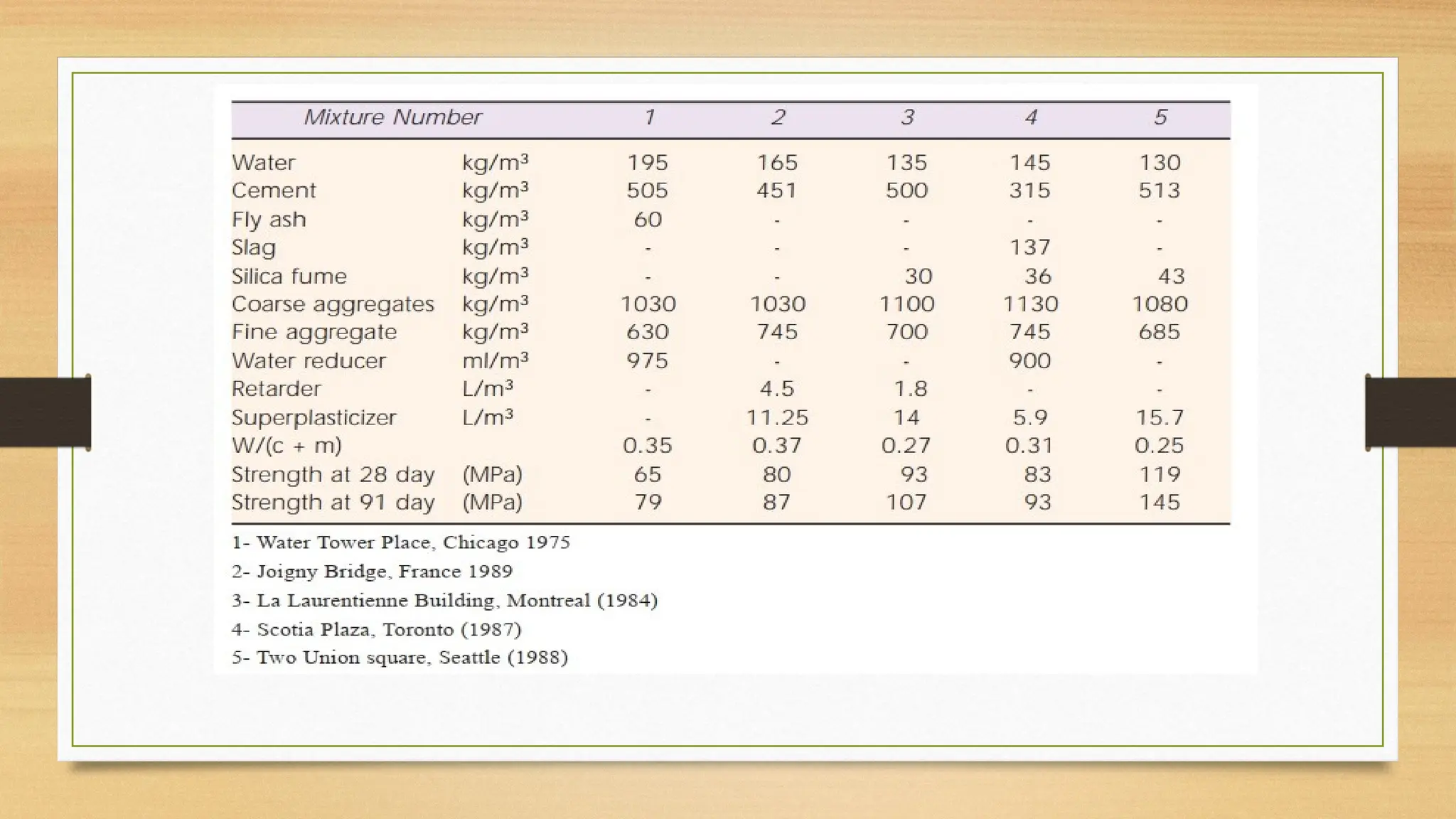

High-performance concrete (HPC) possesses attributes such as high workability, strength, density, and resistance to chemical attack, requiring a low water-to-cement (w/c) ratio for optimal performance. The inclusion of silica fume is essential for achieving strengths above 80 MPa, while the strength of aggregates significantly affects HPC's compressive strength. In India, HPC achieved a strength of 60 MPa in the construction of containment domes at the Kaiga and Rajasthan atomic power projects.