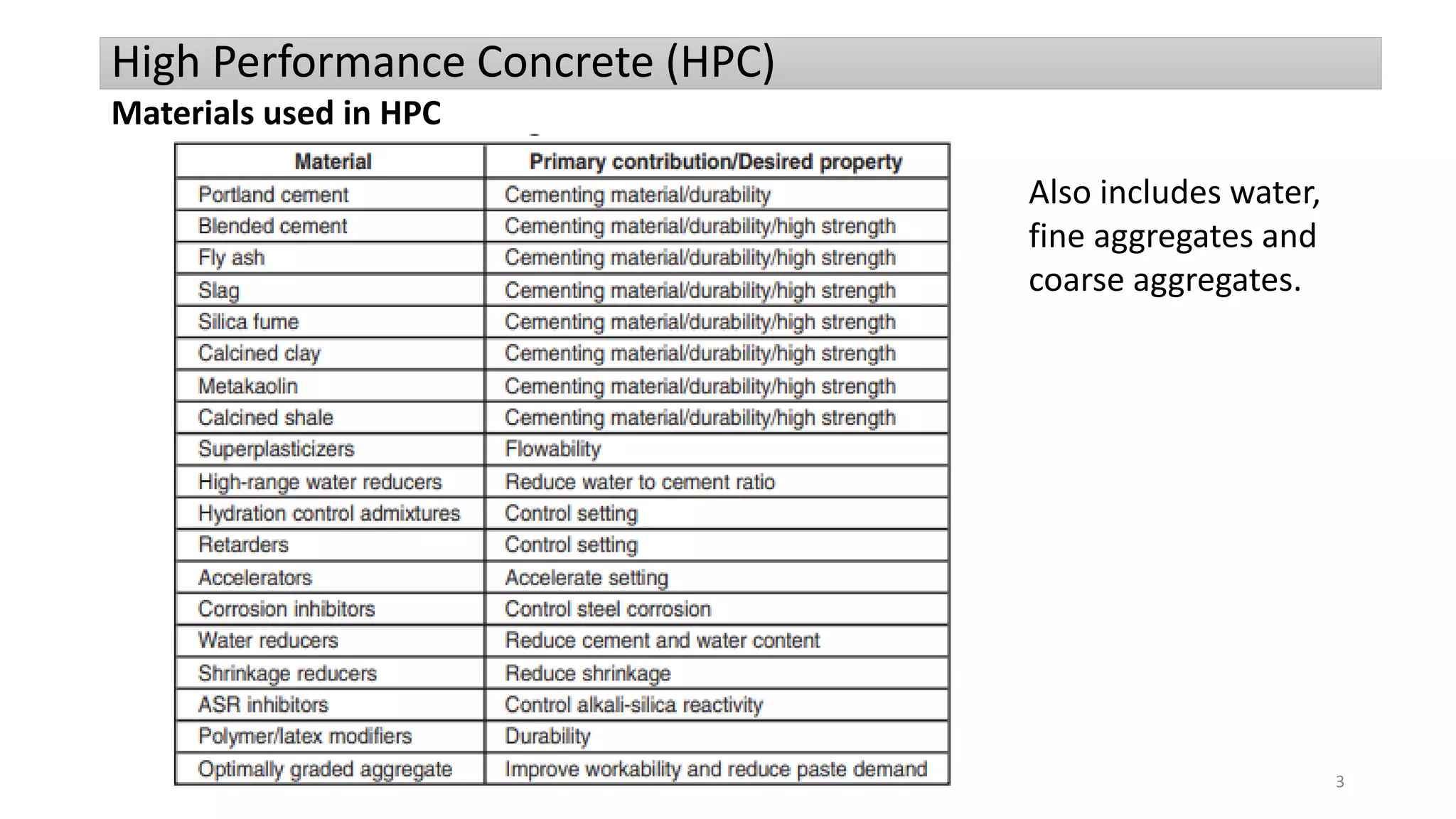

High performance concrete (HPC) is a type of concrete mixture that possesses high workability, high strength, low permeability, and resistance to chemical attack. HPC uses carefully selected, high-quality ingredients and optimized mixture designs to produce concrete with a low water-cement ratio between 0.20 to 0.45. Plasticizers are used to make HPC fluid and workable. HPC exceeds the properties and constructability of normal concrete. It has been used in tunnels, bridges, tall buildings, shotcrete repair, poles, parking garages, and agricultural applications due to its strength, durability, and high modulus of elasticity.