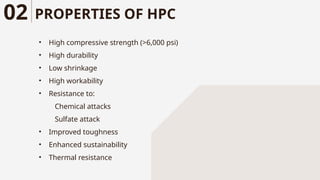

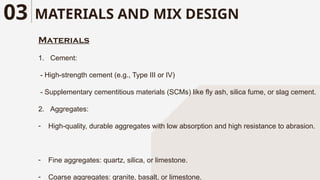

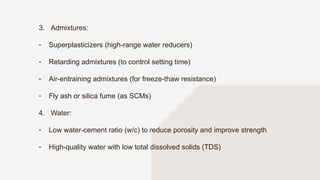

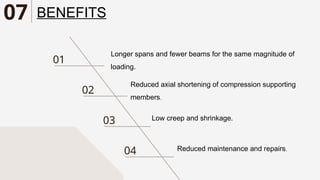

High Performance Concrete (HPC) is a specialized concrete mixture known for its high durability, strength, and unique properties tailored for specific applications, including infrastructure projects. Its formulation incorporates high-strength cements, durable aggregates, and various admixtures, leading to improved workability, reduced permeability, and resistance to environmental degradation. Despite its benefits, HPC requires careful manufacturing, additional testing, and quality control, which can increase costs and complexity.