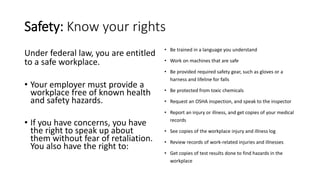

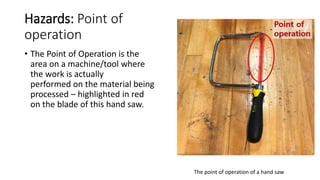

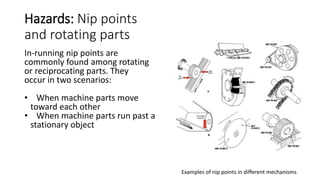

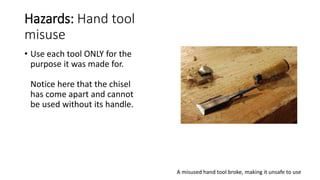

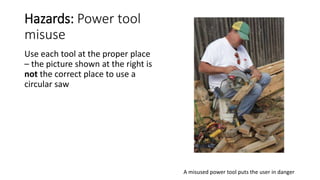

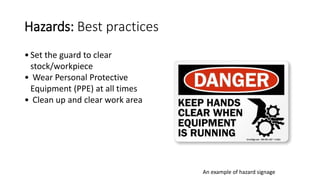

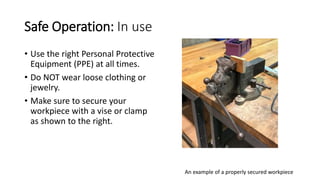

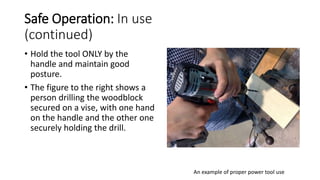

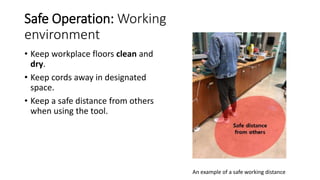

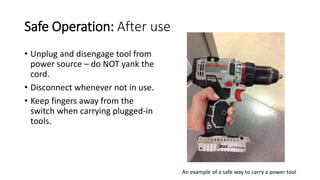

The document provides an introduction to hand tool safety. It discusses what hand tools are, the Occupational Safety and Health Administration (OSHA) and workers' rights, potential hand tool hazards like machine injuries, points of operation, and misuse. It also outlines best safety practices such as using personal protective equipment, securing the workpiece, maintaining good posture, keeping work areas clean and dry, and disconnecting tools after use. The goal is to educate on safety procedures to prevent injuries while operating hand tools.