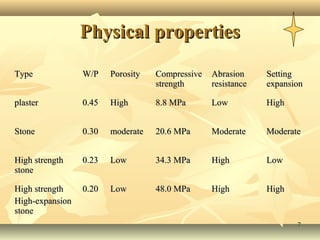

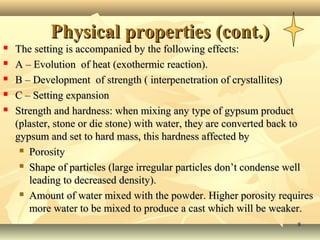

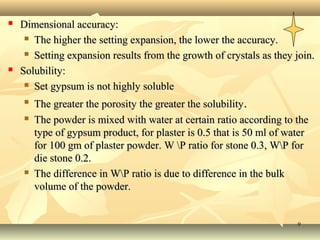

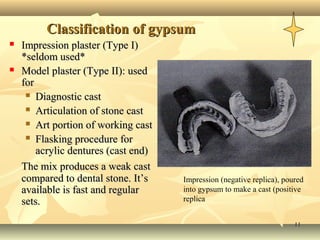

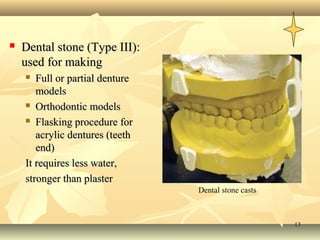

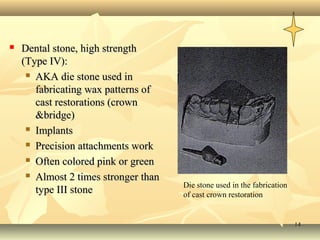

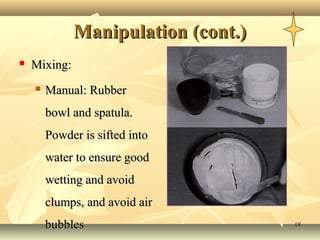

This document discusses the uses and properties of gypsum in dentistry. Gypsum is used to make impression materials, casts, dies and dental molds. There are different types of gypsum products used, including plaster, dental stone, die stone and high strength stones. The properties of these gypsum products such as porosity, strength and setting expansion determine their applications. Plaster is used for diagnostic casts while dental stone is used for full and partial denture models. Die stone is specifically used for fabricating dental restorations and implants.