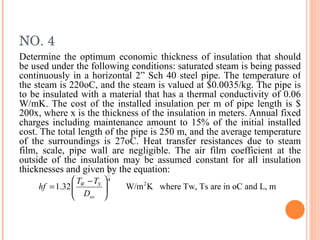

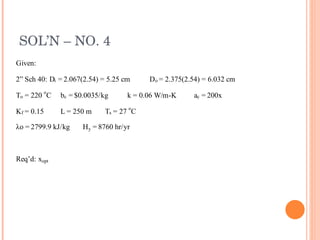

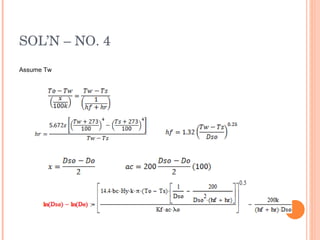

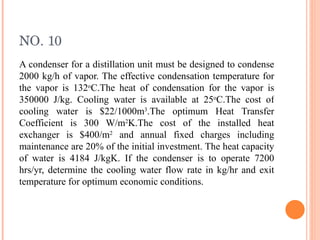

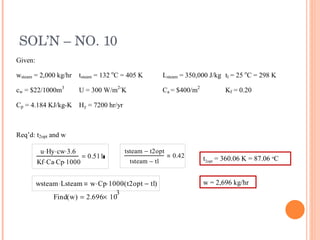

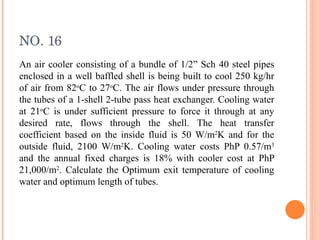

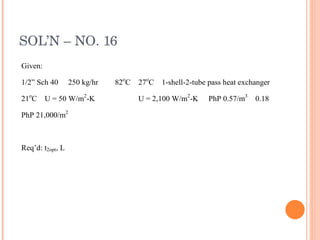

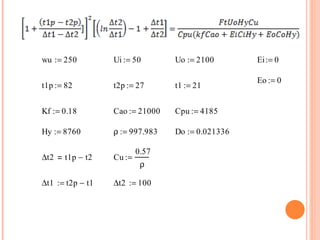

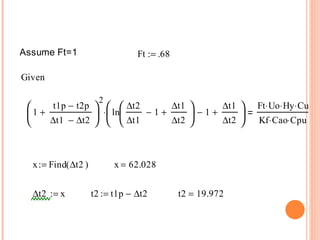

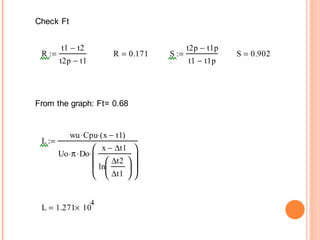

The document discusses optimization problems related to heat transfer in pipes and condensers. It provides conditions for four problems involving determining optimum insulation thickness, steam temperature, cooling water flow rate and exit temperature, and optimum tube length and exit cooling water temperature. Solutions are provided for each problem, calculating key parameters needed for optimal economic performance of the heat transfer systems.