Embed presentation

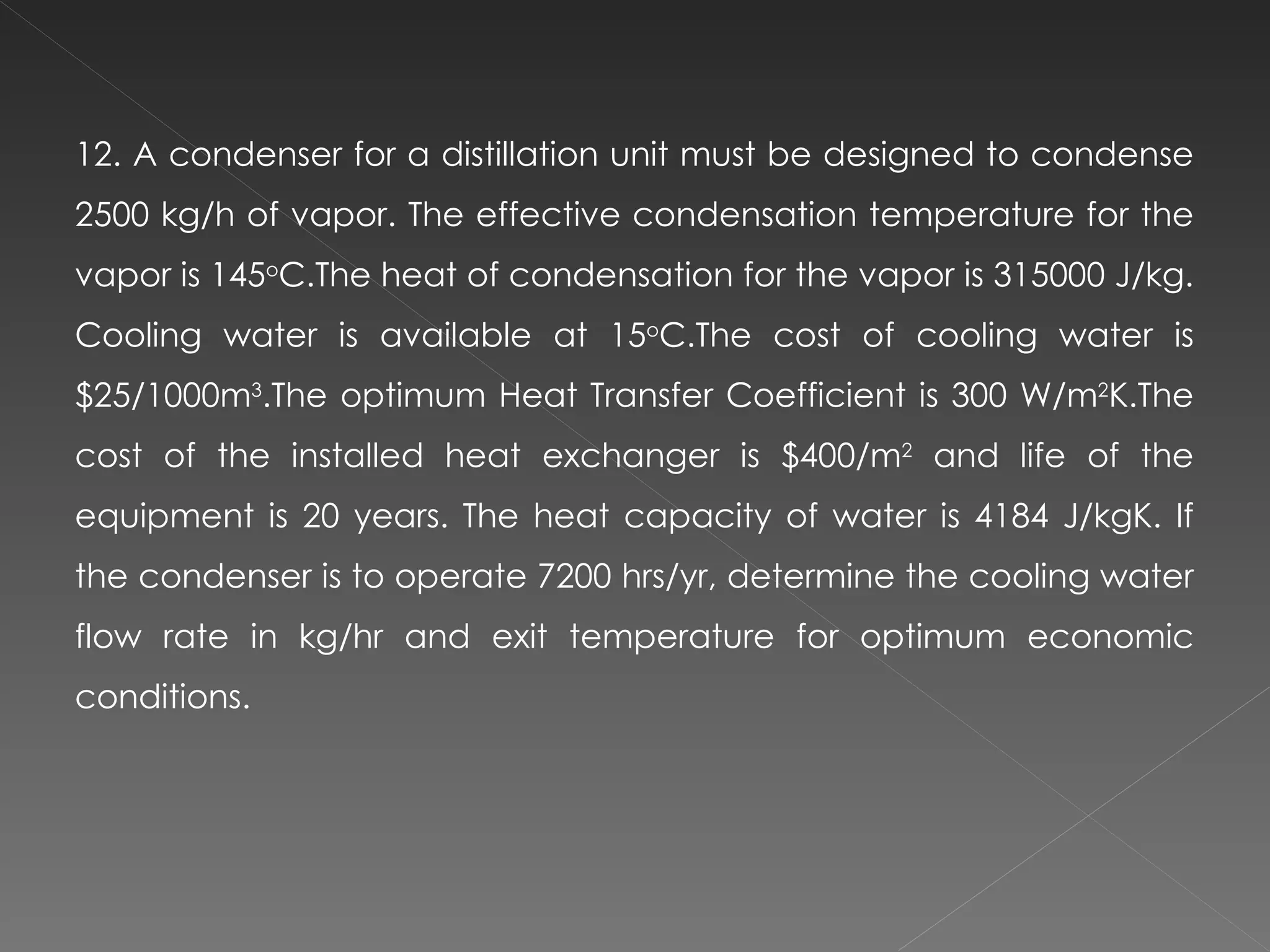

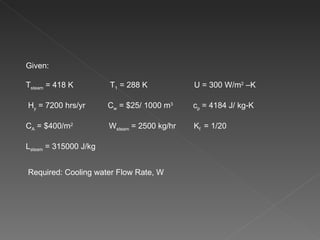

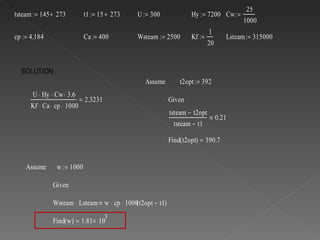

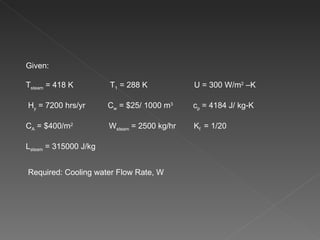

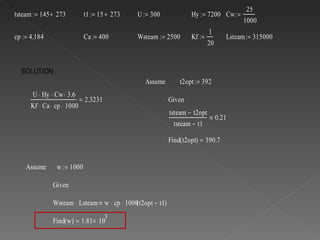

The document provides specifications for designing an optimal condenser for a distillation unit, including the vapor flow rate, heat of condensation, available cooling water temperature, cost of cooling water, optimum heat transfer coefficient, cost and life of the heat exchanger. It asks to determine the cooling water flow rate and exit temperature that would result in optimal economic conditions based on these parameters.