Embed presentation

Download to read offline

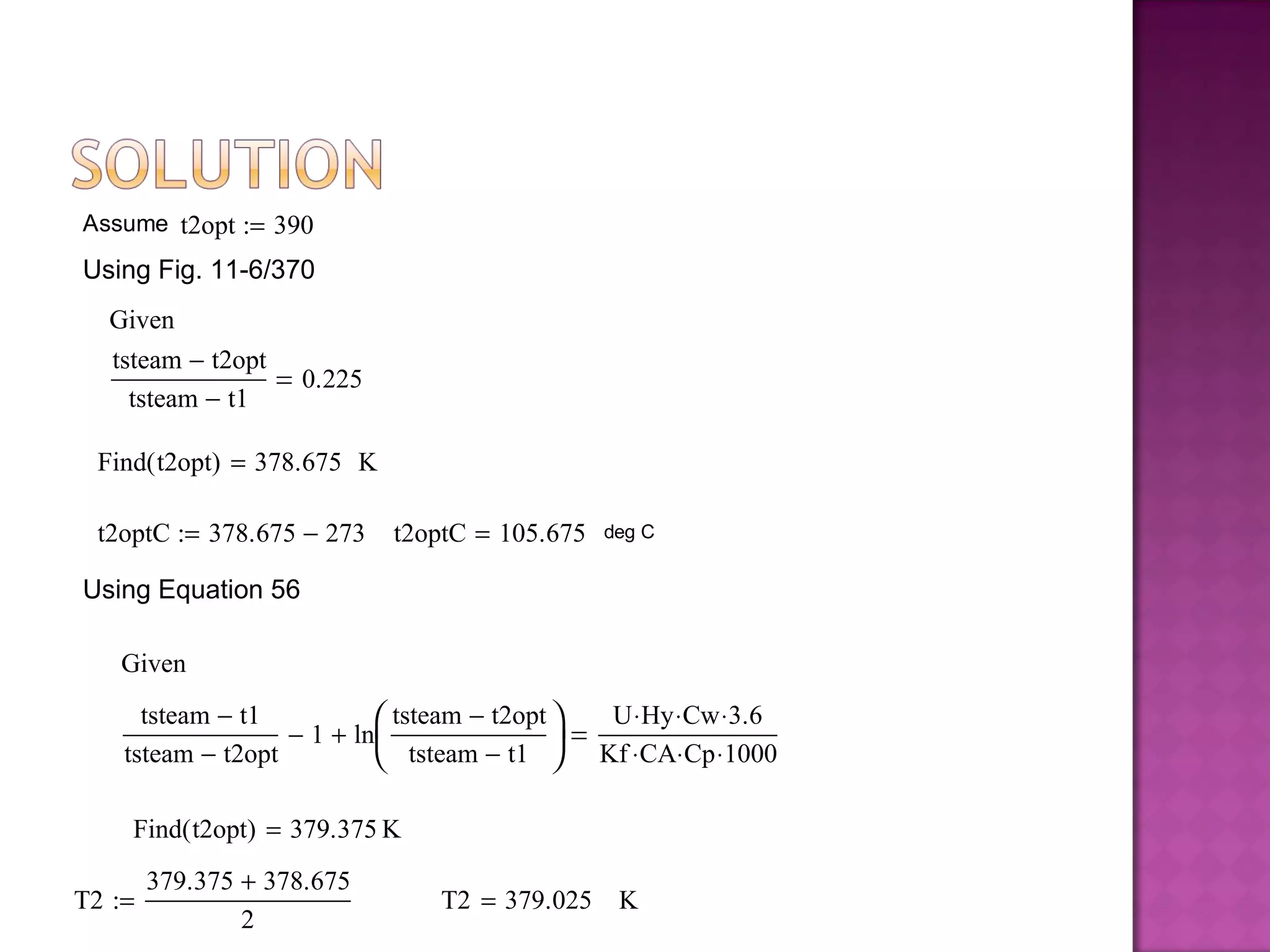

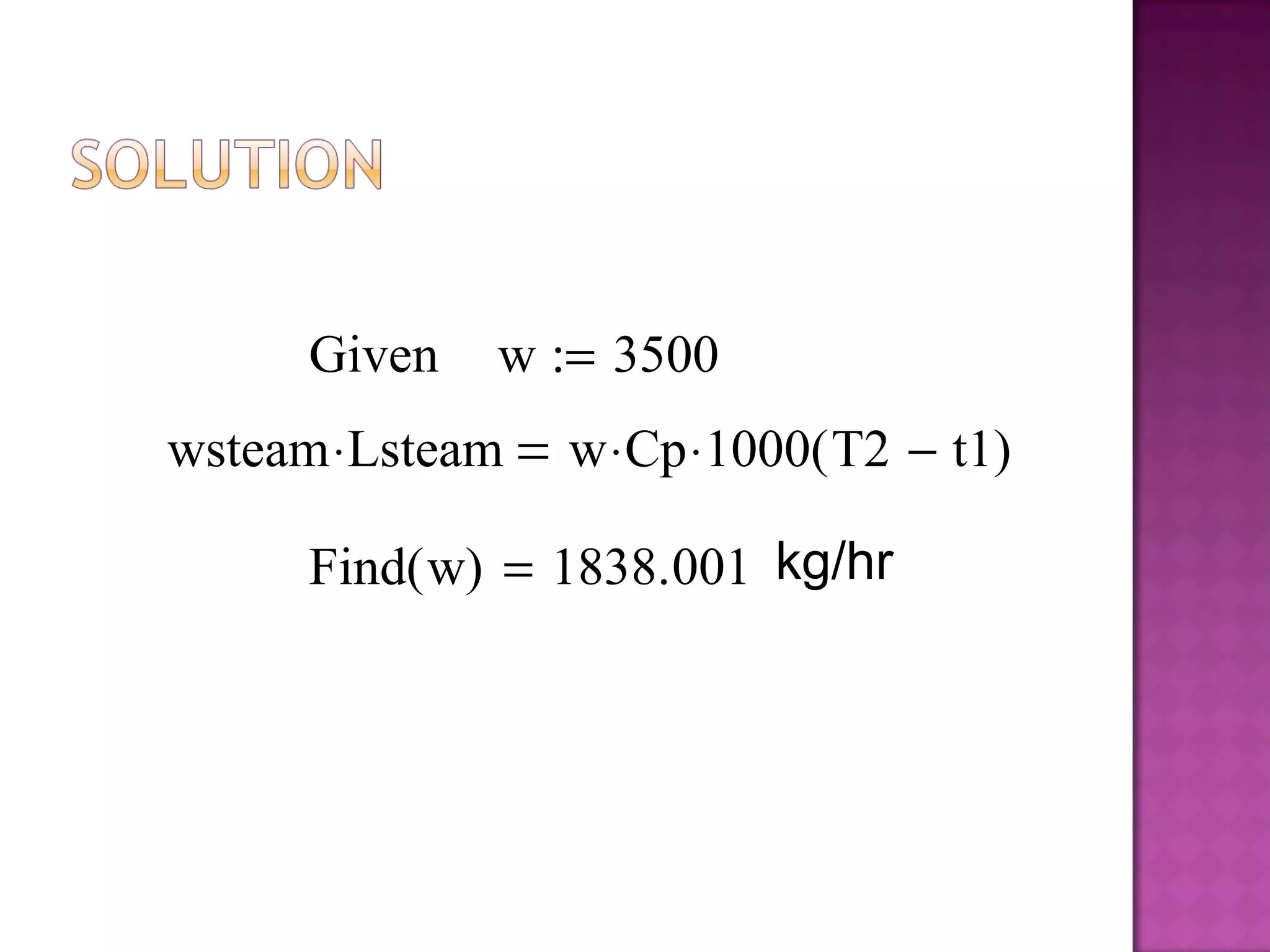

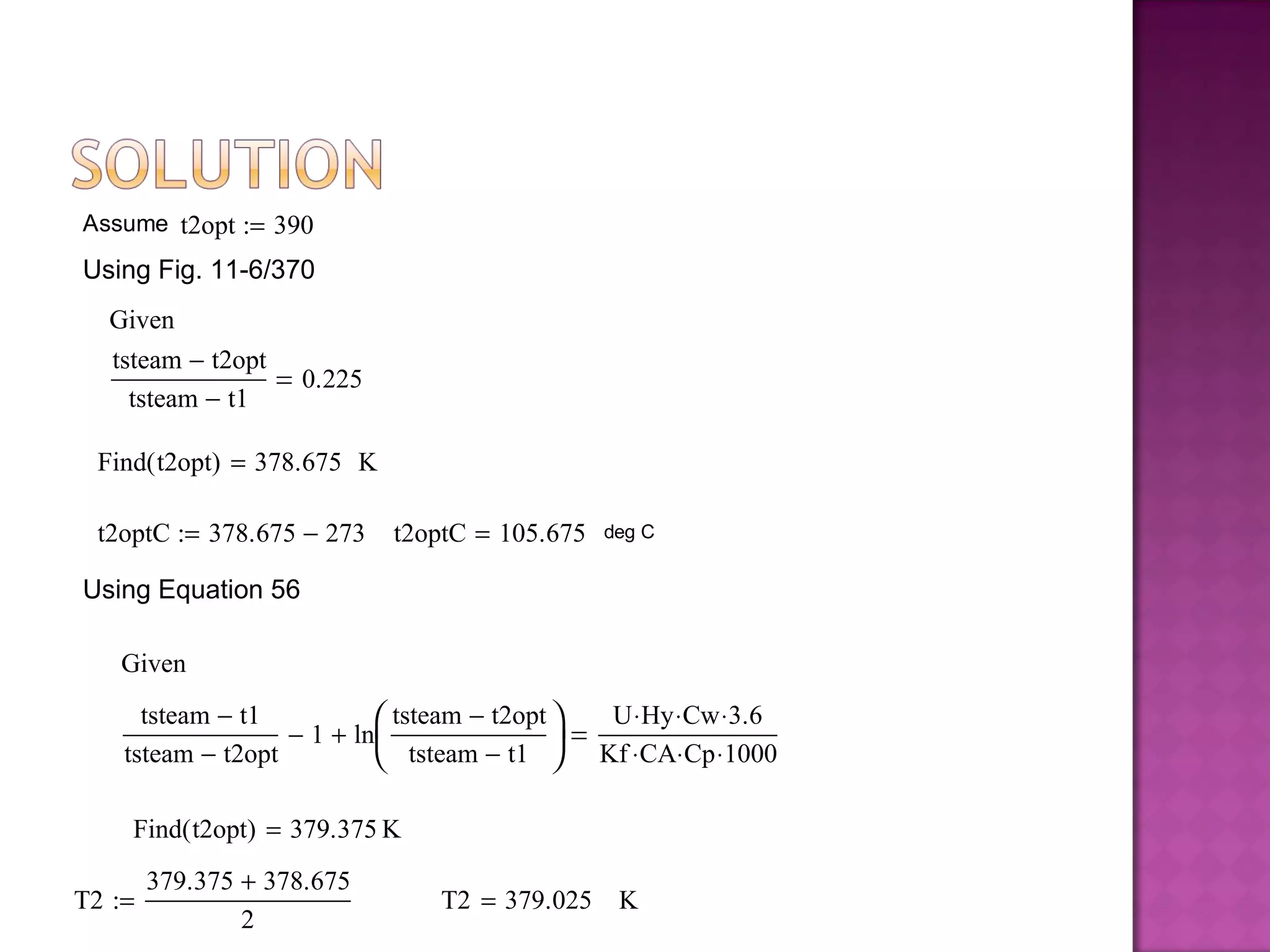

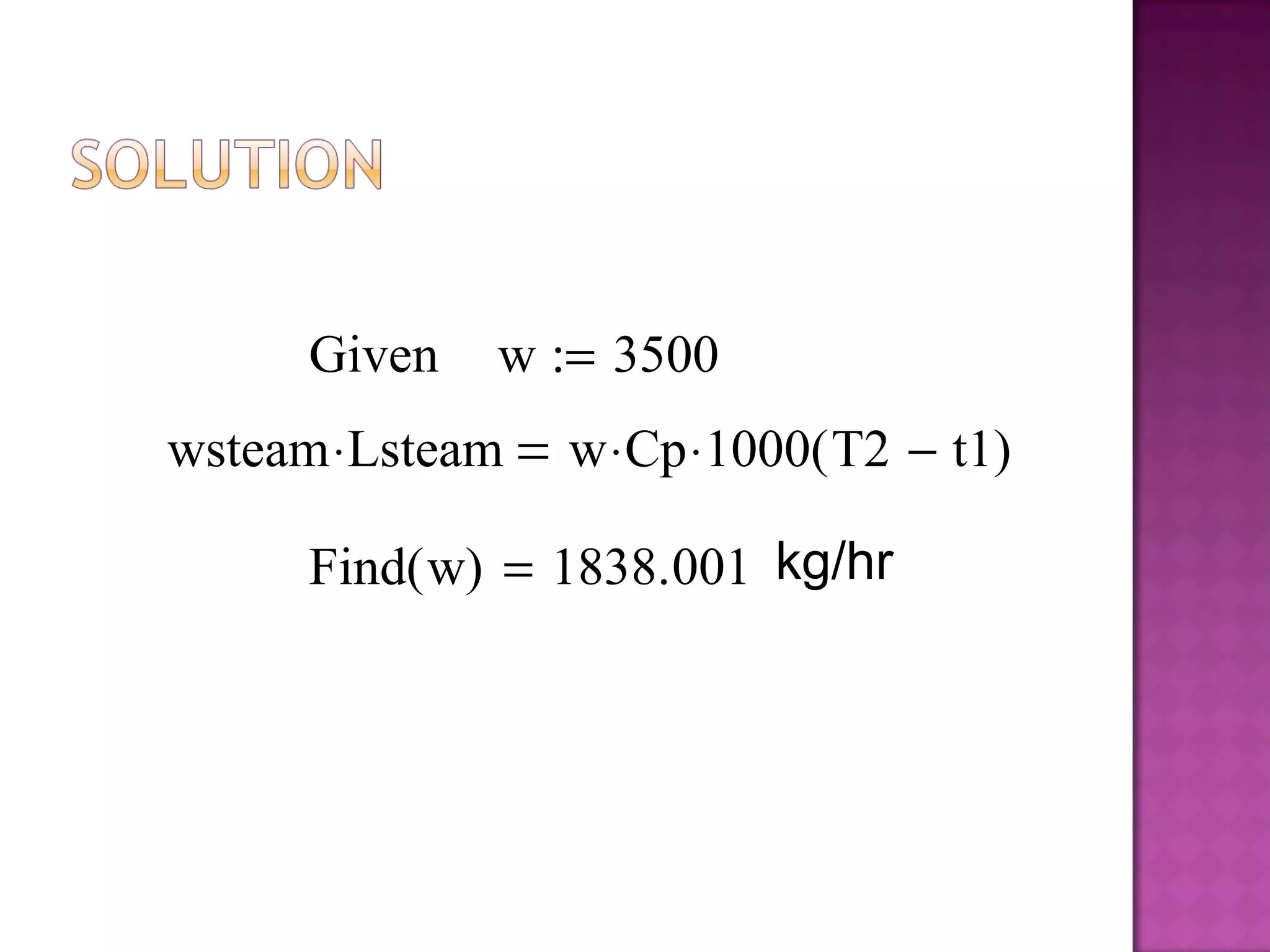

A condenser needs to be designed to condense 2000 kg/h of vapor at 132°C with a heat of condensation of 350000 J/kg. Cooling water is available at 15°C, and the optimum design calls for a heat transfer coefficient of 300 W/m2K. The task is to determine the cooling water flow rate and exit temperature that provides the most economical operation over 10 years.